In today’s competitive market, staying ahead requires more than just innovation. Adopting the latest toothbrush manufacturing technology is essential for meeting toothbrush production standards. This technology ensures high efficiency, precision, and quality in the production process, making it a key factor in the success of any toothbrush manufacturing business.

Toothbrush manufacturing technology has made great strides in precision. Automated systems and advanced machinery ensure that each toothbrush is produced to exact specifications, reducing the chances of errors. Meeting toothbrush production standards requires maintaining strict control over design details, and the latest technology allows for more accurate production processes.

One of the biggest advantages of using modern toothbrush manufacturing technology is the speed it brings to the production line. Automated systems and optimized workflows allow for faster production cycles, helping manufacturers meet high demand without sacrificing quality. Adopting this technology ensures that businesses can maintain efficiency and meet toothbrush production standards even during peak production periods.

To meet toothbrush production standards, manufacturers must ensure that their products meet rigorous quality requirements. The latest toothbrush manufacturing technology incorporates features like quality control sensors and automated inspections, ensuring that each toothbrush meets the highest standards. This minimizes defects and ensures that products consistently perform as expected.

Modern manufacturing technology also plays a significant role in promoting sustainability. By adopting energy-efficient machinery and waste-reducing techniques, manufacturers can minimize their environmental footprint. This helps meet the increasing demand for eco-friendly products while ensuring that toothbrush production standards are still met without compromising quality.

The adoption of toothbrush manufacturing technology also leads to more cost-efficient production. With improved automation and streamlined processes, manufacturers can reduce labor costs and minimize waste. This scalability ensures that as demand increases, the production process can quickly adapt while maintaining toothbrush production standards and profitability.

Meeting toothbrush production standards involves complying with a variety of industry regulations, from safety to environmental guidelines. By integrating the latest toothbrush manufacturing technology, manufacturers can stay up-to-date with the regulatory requirements, ensuring that their products are safe for consumers and compliant with international standards.

Adopting the latest toothbrush manufacturing is not just about keeping up with trends—it’s about meeting toothbrush production standards effectively and efficiently. The benefits, including enhanced precision, faster production, better quality, and sustainability, make it an essential investment for manufacturers looking to stay competitive in the global market. By leveraging these technologies, manufacturers can ensure high-quality products, meet regulatory standards, and remain responsive to changing market demands. Contact us

.jpg)

.jpg)

OEM Oral Care Products for Global Brands and Distributors

.jpg)

Why Dentin Exposure Risk with UV Light Risks?

Manufacturing the Most Effective Home Teeth Whitening Products for Your Brand

Custom Electric Toothbrush Packaging – Retail & Wholesale Options

.jpg)

Dual-Motor Electric Toothbrush OEM Solutions for Premium Oral Care Brands

How to Evaluate an Electric Toothbrush Factory’s Comprehensive Capabilities

.jpg)

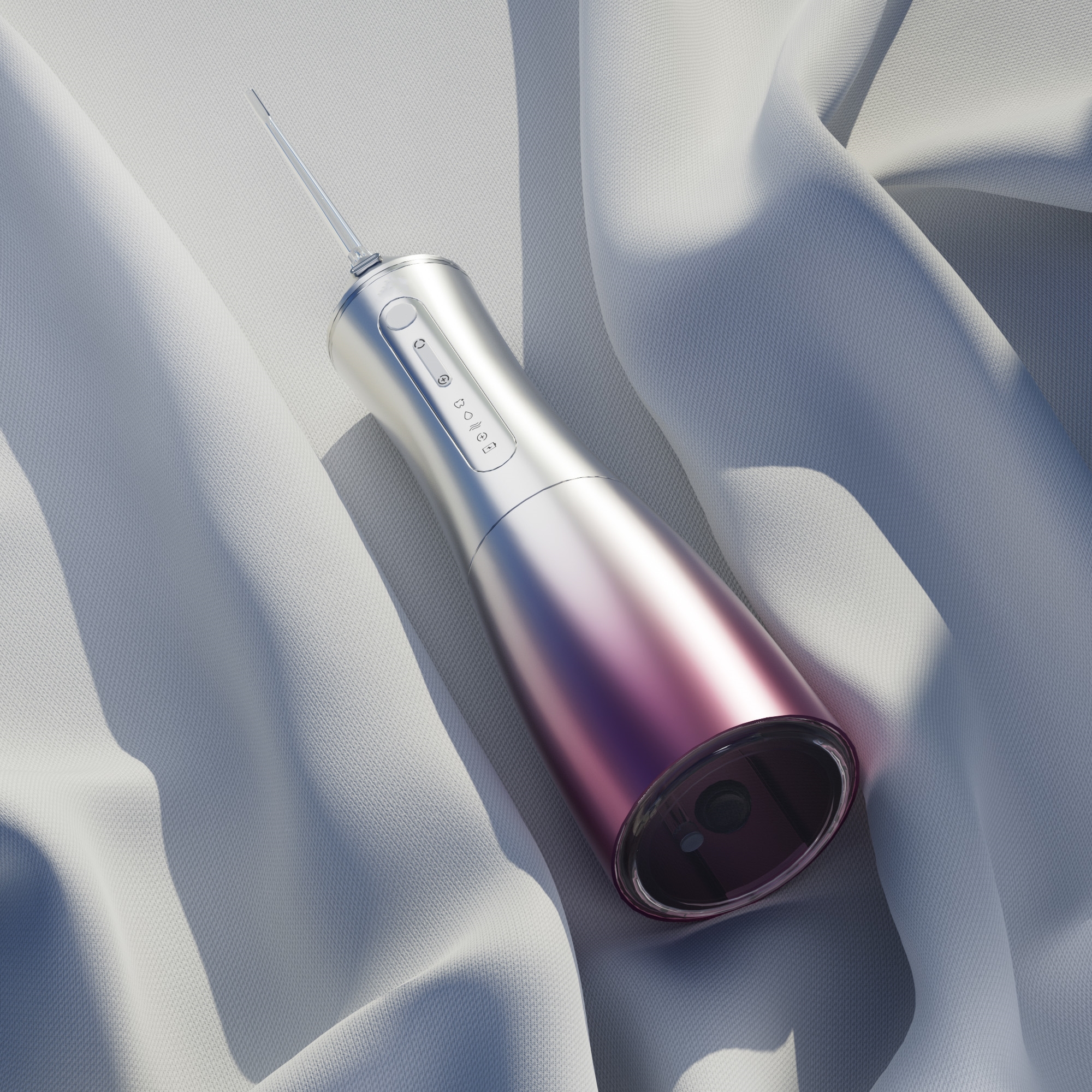

Must-Have Features for a Market-Leading Water Flosser

.jpg)

Boston Electric Toothbrush for Sensitive Gums: Gentle Yet Powerful

.jpg)

Can California pressure sensor tech power an LA affordable toothbrush? A B2B roadmap

What Makes a High-Quality Water Flosser? Material Choices for Durability and Performance

.jpg)

Portable Teeth Whitening Pen Supplier – OEM/ODM Private Label Solutions

.jpg)

Electric Toothbrush for Dental Kit Programs

.jpg)

New Year Resolution for Better Oral Health | Powsmart

Advantages and Disadvantages of Electric Toothbrushes

.jpg)

Electric Toothbrush Houston – Advanced Oral Care for Bright Smiles

Do I Need to Consider the Appearance Design When Choosing an Electric Toothbrush?