In the competitive oral care market, electric toothbrush manufacturers must deliver consistent product quality while managing potential risks effectively. One of the most crucial ways to ensure product reliability is through a robust traceability of electric toothbrushes. Especially for key components like motors and the waterproof casing, strict control through motor calibration standards and a detailed waterproof test process is vital. Together with proper quality inspection record archiving, these measures help maintain brand reputation and significantly contribute to product recall prevention.

The motor is the heart of any electric toothbrush, directly impacting performance, user experience, and product life. Adhering to precise motor calibration standards ensures that each unit operates within specified parameters, including:

Rotational speed (RPM) consistency

Vibration strength within optimal ranges

Noise level control to enhance comfort

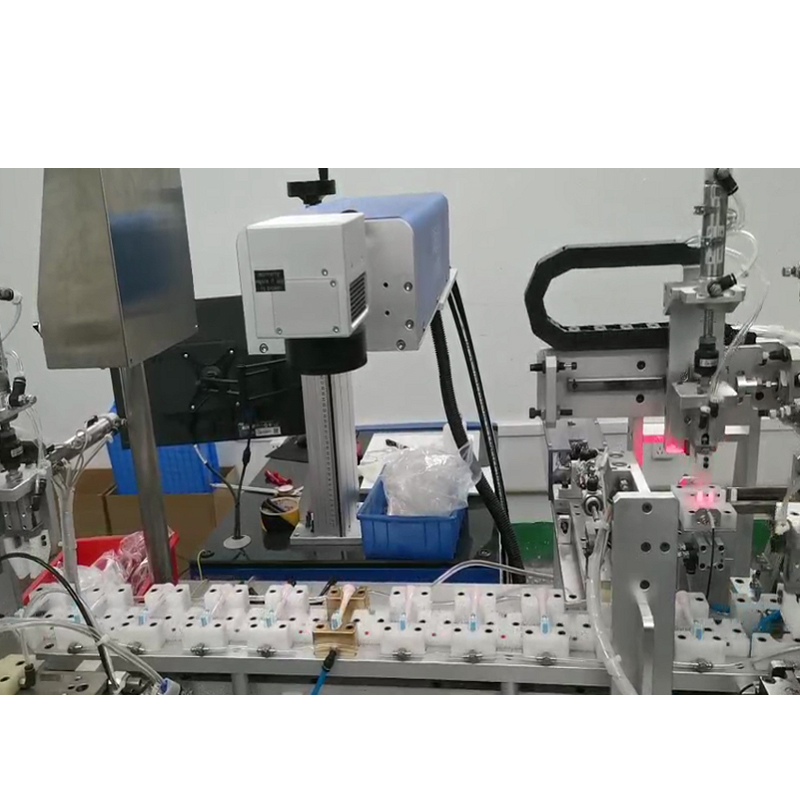

During production, every motor undergoes calibration using specialized testing equipment. Detailed calibration data are recorded in the production traceability system, linking each motor to its corresponding toothbrush serial number. This practice guarantees that any deviation can be traced back instantly.

Daily exposure to water makes the waterproof test process critical for electric toothbrushes. The standard testing procedures typically include:

IPX7 or IPX8 level testing (depending on product design)

Simulated submersion and spray testing

Seal integrity inspections after assembly

Each unit must pass waterproof testing before packaging. Testing results are digitally logged into the system for full traceability, supporting both quality assurance and future troubleshooting.

A complete taceability of electric toothbrushes captures detailed data at every critical stage, including:

Component sourcing information (e.g., motor batch numbers, casing material suppliers)

Assembly records (e.g., assembly line, operator ID)

Calibration and testing results (e.g., motor RPM, waterproof test pass/fail results)

Using barcode or RFID tagging, each product’s full manufacturing history is stored in an integrated database, accessible for audits, client reports, or after-sales service.

Proper quality inspection record archiving ensures that all data related to motor calibration, waterproof testing, and final inspections are securely stored for the long term. Best practices include:

Digital archiving to prevent loss or damage of physical documents

Cloud-based systems to allow remote access and enhanced security

Periodic audits to verify record accuracy and completeness

This system not only supports internal process improvements but also acts as strong evidence in regulatory compliance and client quality assurance reporting.

By enforcing strict motor calibration standards, executing a thorough waterproof test process, building an effective traceability of electric toothbrushes, and maintaining detailed quality inspection record archiving, manufacturers can greatly enhance product reliability.

More importantly, these steps are crucial to product recall prevention — protecting brand reputation, minimizing financial loss, and ensuring customer trust.

Partnering with a professional manufacturer who values process traceability is the first step toward producing world-class electric toothbrushes.

Contact our team today to learn how our traceability and quality management systems can support your OEM/ODM electric toothbrush projects!https://www.powsmart.com/oral-care-products-private-label/

How to Handle Temperature Spikes and Handle Slippage?

.jpg)

A Complete Guide to OEM Customization of Electric Toothbrushes: From LOGO Printing to Core Function Development

How a Gentle senior brush protects Sensitive elderly gums

Why a College essential toothbrush tops Student oral care lists

How Can Gradient Color Injection Molding Technology Improve the Attractiveness of Electric Toothbrushes?

Gentle Electric Toothbrush for Sensitive Aging Gums

Food-Grade Materials Solve Gum Irritation?

Traditional Values Modern Electric Toothbrush India

-2-scaled.png)

Different Selling Points of Teeth Whitening Devices: Portable, APP-Linked, Gel Customization. Which Selling Point Attracts the Most Attention from Brands?

.jpg)

Does a Clinic strength brush qualify as an India medical toothbrush standard?

Could Your Toothbrush Be Damaging Gums?

Why Does Whitening Efficacy Decline Trigger Pulse Intensity Spikes?

How to Make Your Own Electric Toothbrush

Why Dentist Consultations Mitigate Home Treatment Risks?

How Does Maintenance Difficulty Worsen Enamel Weakness?

.jpg)

How Can a Travel-Friendly Water Flosser Open Up the Young Market Through Portable Size + IP Collaboration?

electric toothbrush heads Ultra Soft

electric toothbrush heads Deep Clean

electric toothbrush heads Regular Clean

Private Label Whitening Gel

electric toothbrush heads Charcoal Infuse-Round

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Customization Teeth Whitening Gel

Electric toothbrush heads Charcoal Infused-Diamond

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638