When seal degradation is left unchecked in oral care and hygiene devices, the result can be more than just cosmetic wear. A compromised seal allows moisture and organic debris to accumulate internally, creating the perfect environment for bacterial regrowth. Over time, this invisible contamination can undermine product safety, degrade user experience, and expose manufacturers to significant liability. So is this problem preventable? With proactive design and production measures, the answer is a resounding yes.

Seal degradation is the process by which gaskets, O-rings, or adhesive barriers lose their integrity. This can occur for several reasons:

Once these seals fail, pathways open for moisture infiltration and microbial contamination.

Bacterial colonies thrive in warm, damp spaces. When a degraded seal allows saliva, cleaning fluid, or even tap water to seep into the device:

This process fuels bacterial regrowth, which can persist despite surface cleaning. Company web: https://www.powsmart.com/product/electric-toothbrush/

For OEMs and distributors, identifying seal degradation before bacterial contamination escalates is critical. Look for these early indicators:

Routine visual inspections and periodic pressure tests help catch leaks before they become systemic.

To stop seal degradation and control bacterial regrowth, manufacturers can adopt proven best practices:

When combined, these measures help maintain a sterile internal environment over the entire product lifecycle.

Even with excellent engineering, defects occasionally occur. Leading manufacturers can protect partners by:

Clear documentation and transparent warranty support reassure distributors and retailers that user safety is always a top priority.

Unlike cosmetic blemishes, seal degradation combined with bacterial regrowth is a potentially serious health hazard. However, this threat is fully preventable with robust design, disciplined manufacturing, and proactive maintenance protocols. By taking these steps early, B2B suppliers protect end users, strengthen brand reputation, and stay ahead of increasingly strict hygiene regulations in global markets.

Conclusion

If you’re designing or sourcing oral care equipment, remember: a small seal can be the most critical barrier between your device and contamination. Invest in premium materials, enforce rigorous testing, and empower customers to maintain their devices correctly—so seal degradation and bacterial regrowth never have the chance to become a problem.Contact us

.jpg)

.jpg)

Why Is Pressure Sensor Calibration Important After Brush Head Injection Molding?

.jpg)

Kids Electric Toothbrush Hyderabad | Fun & Gentle Care

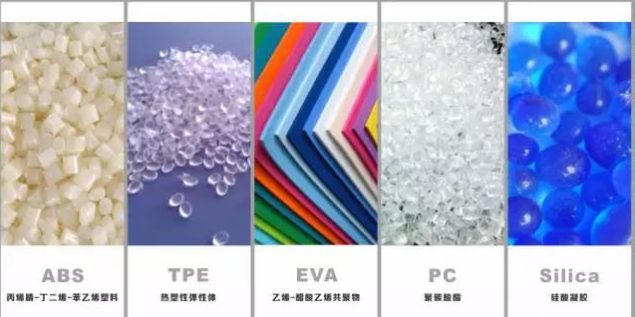

Oral Care Products CPSR Material List: Ensuring Safety and Compliance

Quality of Product is Vital to the Success of an Enterprise

.jpg)

Need a Transparent Electric Toothbrush Cost Breakdown to Build a Strong Electric Toothbrush Supplier Relationship?

.jpg)

USB-C Water Flosser Wholesale | Fast-Charging Oral Irrigator Distributor

.jpg)

Customizable Sonic Toothbrush OEM – Personalized High-Performance Designs for Global Brands

.jpg)

Wholesale Logo Printed Electric Toothbrush OEM Service

.jpg)

smart electric toothbrush OEM | Custom Smart Sonic Toothbrush Manufacturer

Solutions for Easily-Rolling Electric Toothbrush Handles

African Teeth Whitening Habits: Guide for OEM Product Development

.jpg)

Electric Toothbrush Sample Lead Time for OEM Projects

How Long Does It Typically Take to See Results in Teeth Whitening When Using Electrical Oral Care Products?

Bulk Personalized Electric Toothbrush: Custom Manufacturing Services

.jpg)

Clinical Strength Electric Toothbrush Colaba Clinic

Solving Electric Toothbrush Roll & Fall: Product Development Strategies for OEMs