In the realm of oral care devices, fluid-handling components, and consumer appliances, tank scaling is more than just a hygiene concern—it’s a silent disruptor that may lead to part incompatibility. For B2B clients, this doesn’t just translate into performance instability but also impacts assembly efficiency, aftersales costs, and long-term product reliability.

Tank scaling refers to the accumulation of mineral deposits—mostly calcium and magnesium—from hard water inside water tanks and flow systems. It’s especially prevalent in:

Scaling manifests as white residues, internal roughness, and narrow flow paths—often overlooked but extremely damaging to component fit and function.

Although mineral buildup might seem cosmetic, its functional consequences can be severe:

This “invisible misalignment” makes devices appear normal on the outside but faulty during use—often misattributed to poor QC or batch inconsistency.Company web:https://www.powsmart.com/product/electric-toothbrush/

For manufacturers, tank scaling–induced part incompatibility introduces complications across multiple stages:

To safeguard against tank scaling from the outset, consider integrated design-level solutions:

-2-1024x576.png)

Beyond smart design, manufacturers should support end-users with education and maintenance tools:

This proactive approach turns potential product faults into manageable maintenance workflows.

In a market where durability and intelligence drive purchase decisions, resistance to tank scaling—and the prevention of part incompatibility—will become critical value markers:

Embedding scale mitigation into product quality benchmarks ensures higher satisfaction and stronger brand reputation.

Tank scaling may begin as a mineral residue, but it often ends as a functional mismatch. For manufacturers targeting high-precision, long-lifecycle B2B products, proactively managing scaling risks and preventing part incompatibility is a fundamental step toward quality excellence.

Looking to engineer scale-resistant water systems or need support in optimizing your fluid-based product design? Contact us for technical consultation and tailored development solutions.

Kids Water Flosser Age Guide: When to Introduce and How to OEM the Right Product

.jpg)

custom color electric toothbrush | Color Customization Electric Toothbrush OEM

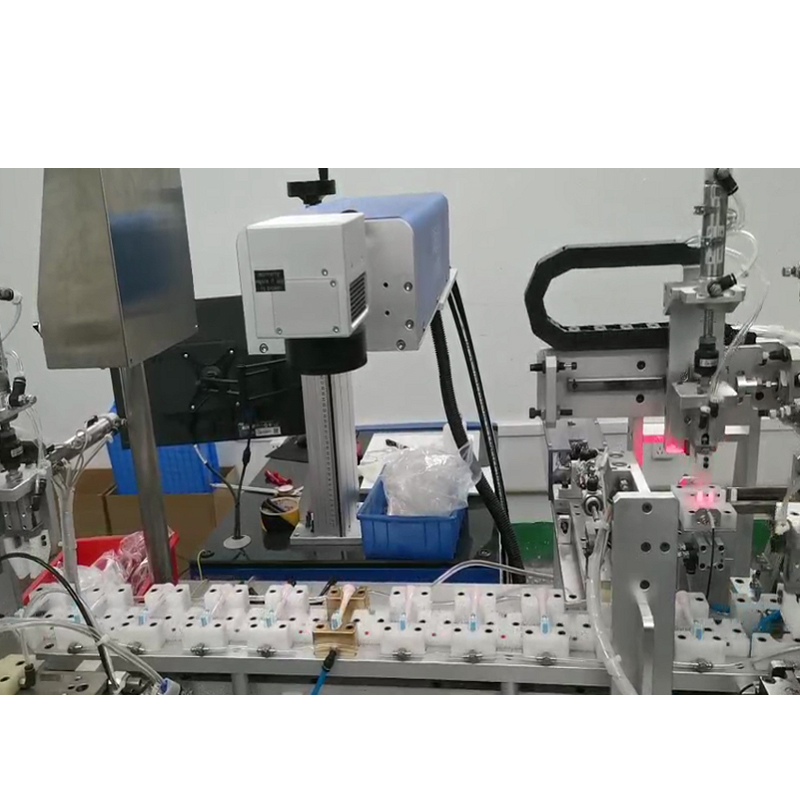

Electric Toothbrush Laser Engraving LOGO Process: How to Set the Depth, Speed and Power Parameters?

.jpg)

Hose Kinking Leading to Weak Suction—A Hidden Efficiency Killer?

How Does Ethical Toothbrush Material Sourcing Contribute to a Sustainable Toothbrush Product?

About the Battery Maintenance Problem During the Use of Electric Toothbrush

.jpg)

Need funding? Dental grants for WA clinics – how to apply

.jpg)

Teeth Whitener Moldflow & Anti-Mold Process: Ensuring Product Quality and Durability

.jpg)

Luxury Smart Electric Toothbrush Dallas

When North Campus budget meets a Delhi festival offer?

.jpg)

OEM Sonic Toothbrush Manufacturer for Custom Brand Projects

The Science of Light: How Red & Blue LED Technology Enhances Modern Oral Care

.jpg)

Electric Toothbrush Distributor Program – Strategic B2B Partnership Solutions

Can Scalable Toothbrush Production Capacity Optimize Your Toothbrush Material Sourcing Costs?

.jpg)

Do Vibration Weakening and Circuit Short Increase Risks?

Common quality problem with electric toothbrushes