For B2B buyers and OEM/ODM partners, the question isn’t only how green a product looks—it’s whether a Seattle eco toothbrush is engineered for real end-of-life recovery and can plug into local take-back flows. Below we outline six manufacturer-focused dimensions—design, materials, electronics, reverse logistics, packaging/comms, and KPIs—to ensure your electric line aligns with Seattle toothbrush recycling programs while preserving margin and user experience.

First, clarify the expectations in eco-aware metropolitan markets. Seattle shoppers reward brands that make recycling effortless and transparent. Therefore, position the Seattle eco toothbrush as a product-plus-service:

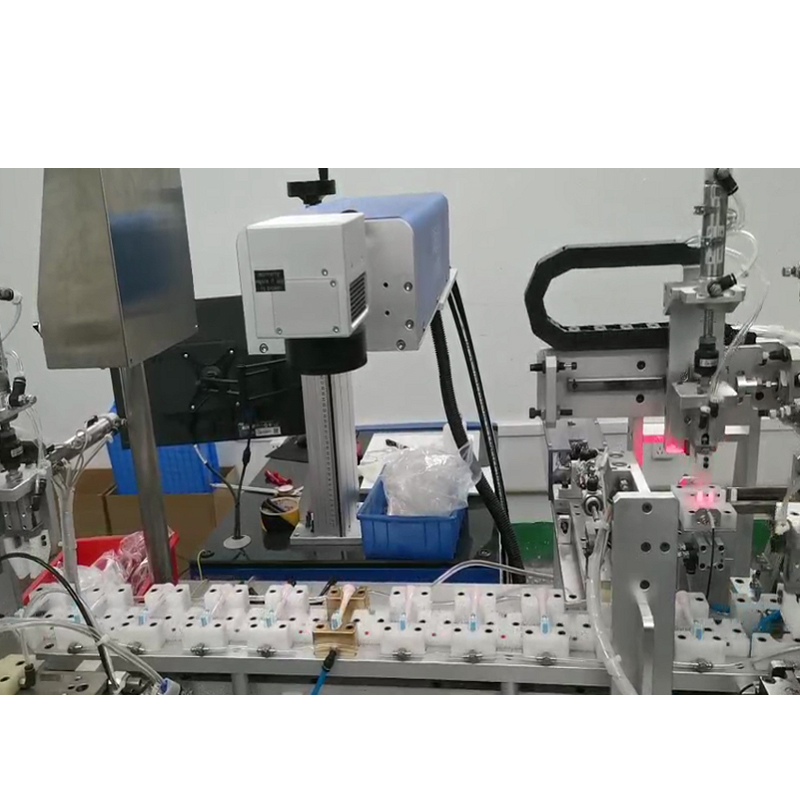

Next, enable quick, tool-light disassembly so parts actually get recycled:

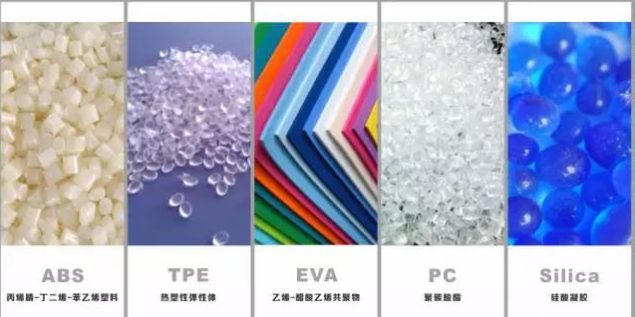

Moreover, choose materials that balance sustainability with clinical performance:

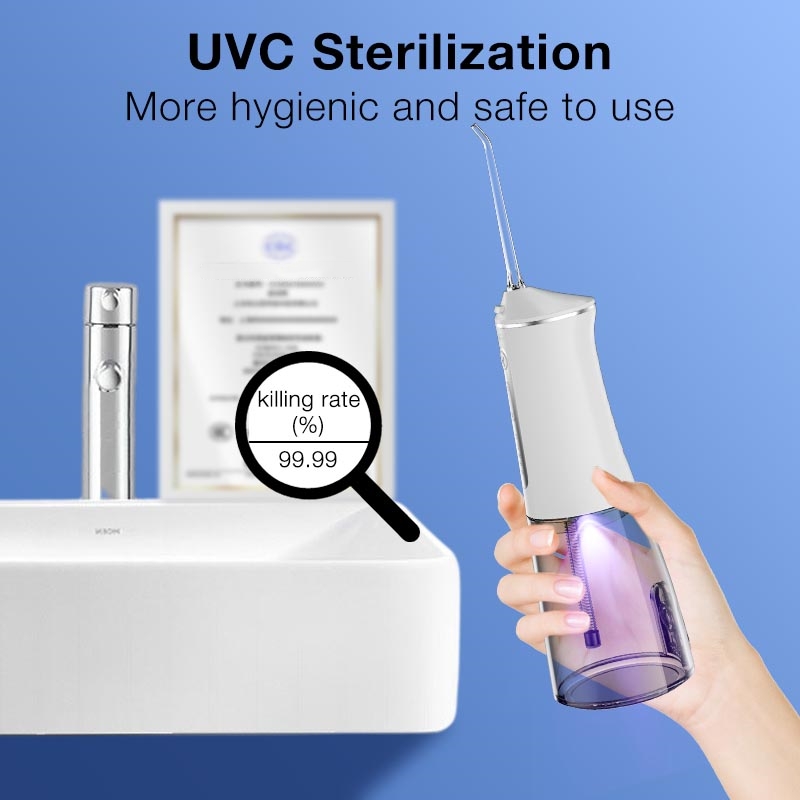

Furthermore, the electronics architecture must support safe recovery:

Meanwhile, align operations so users naturally return items:

Finally, convert eco engineering into measurable value:

To align an electric Seattle eco toothbrush with real-world Seattle toothbrush recycling programs, B2B teams should:

Looking for a ready-to-ship spec pack (DfD drawings, resin callouts, battery sled CAD notes, tear-down SOP, and a pilot KPI dashboard) tailored to your factory and retail partners? I can draft it in a production-ready format. Contact us

.jpg)

Need Toothbrush Bristles from a Toothbrush Parts Supplier?

Does the 40000 Strokes/Min Sonic Brush Trigger Gum Recession?

What is the Core Technology of the Oral Irrigator?

Is Small Batch Customization Feasible? The Minimum Order Quantity and Cost Control of Electric Toothbrush Labeling

Oral Care Products CPSR Material List: Ensuring Safety and Compliance

.jpg)

Taste Distortion Alongside pH Imbalance – Vicious Cycle?

.jpg)

Can the right oral care products prevent pain this National Toothache Day?

Cost Control and Quality Assurance Strategy of Electric Toothbrush OEM Production

.jpg)

Multi-Mode Sonic Toothbrush for OEM Buyers | Advanced Cleaning Modes & Customizable Designs

Does Dental Grade Whitening Necessitate the Use of Safe Whitening Ingredients?

.jpg)

Toothbrush Head Replacement Bulk Supplier | OEM Oral Care Parts

How Does Brush Head OEM Production Integrate with Toothbrush PCB Design for Smart Toothbrush Development?

Reasons to enter the oral irrigators industry in 2024

.jpg)

Reasons for Water Flosser Leaking Problems: OEM Design Insights

How Can Gradient Color Injection Molding Technology Improve the Attractiveness of Electric Toothbrushes?

.jpg)

Biofilm Regrowth Inducing pH Imbalance – Vicious Cycle?