In the development of oral care and medical-grade fluid devices, seal degradation is often an underestimated issue. However, when seal integrity is compromised, it can lead to unintended pressure irregularities, fluid leaks, or component misalignment—conditions that directly contribute to tissue trauma during user interaction. For B2B manufacturers and OEM/ODM partners, exploring this link is critical to reducing user complaints and enhancing product performance.

Seal degradation refers to the gradual breakdown of sealing materials used in devices such as water flossers, irrigators, or other pressurized instruments. This degradation may be caused by:

Once degraded, seals can become brittle, lose elasticity, or even crack, resulting in a partial or complete loss of containment.

When a seal begins to fail, pressure regulation becomes unstable. This often results in:

This unstable delivery system is not only inefficient—it may also direct water or air at unpredictable angles and intensities, inadvertently causing tissue trauma, particularly to delicate oral mucosa. Company web:https://www.powsmart.com/product/electric-toothbrush/

.jpg)

Tissue trauma refers to localized damage such as:

In a water flosser or similar oral hygiene device, such injuries are typically caused by forceful, uncontrolled jets or misdirected fluid due to degraded seals. Users may attribute the problem to the nozzle or motor, when in fact, the root cause lies deep within the internal sealing system.

From a production standpoint, seal degradation is challenging to detect during routine quality checks because:

This disconnect often leads to recurring complaints of pain or discomfort with no obvious cause, undermining product reputation.

To reduce the incidence of tissue trauma linked to seal degradation, manufacturers can consider:

These measures help ensure consistent internal pressure and fluid containment throughout the device’s lifecycle.

Ignoring seal degradation is not just a technical risk—it’s a business risk. For B2B clients, this oversight can lead to:

Proactively addressing seal quality safeguards both user health and product longevity—two key metrics for any brand’s success.

In summary, seal degradation can silently compromise device functionality and user comfort, ultimately leading to tissue trauma. By recognizing this relationship, B2B manufacturers can refine design specifications, enhance QC protocols, and strengthen their position in a competitive market focused on safety and performance. Contact us

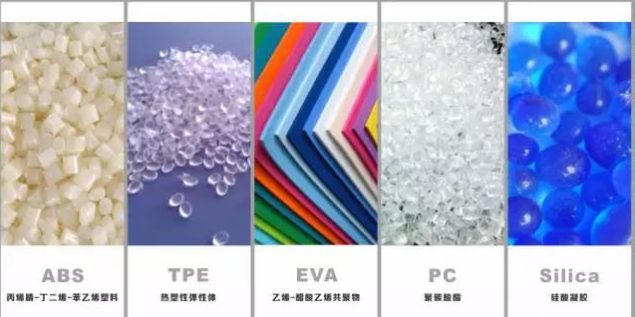

What Are Electric Toothbrushes Made of?

.jpg)

Sourcing Water Flosser Manufacturers: Key Considerations for Oral Care Brands

Improve Smile with Electric Toothbrush: OEM Customization Options

Oral Irrigator Factory Tell You How to Keep Water Flosser from Spraying Everywhere

.jpg)

Los Angeles Teeth Whitening Kit Wholesale

.jpg)

Solution for Color Customization of Water Flossers: From Pantone Code to Actual Machine – A Comparison of Two-Color Injection Molding and Gradient Spraying

Comparing Button Types in Electric Toothbrushes: Which is Best for Your Product?

.jpg)

Texas Wedding Guest Gift Electric Toothbrush

From manual to electric toothbrushes: a revolution in changing toothbrush habits

Is Whitening Kit Certification Necessary for Marketing a Portable Whitening Kit Globally?

.jpg)

Powsmart Electric toothbrush Factory Springdale Arkansas

OEM Electric Toothbrush Quality Manufacturing in USA Texas

How Can Toothbrush OEM Manufacturing Services Boost Your Custom Toothbrush Branding Strategy?

.jpg)

Hospital Grade Electric Toothbrush Supplier

.jpg)

Quiet Operation Electric Toothbrush for OEM | Low-Noise Sonic Cleaning for Premium Markets

.jpg)

How to Choose a High-Profit Electric Toothbrush? A Must-Read Guide for Distributors