Strong electric toothbrush OEM capabilities are essential for international distributors and private-label brands seeking long-term competitiveness in oral-care markets. When selecting an OEM partner, buyers often evaluate technical strength, manufacturing scale, design flexibility, and regulatory compliance. As markets continue to expand, choosing an experienced supplier becomes even more important for brand differentiation.

Leading OEM manufacturers typically offer full in-house engineering services. These include structural design, PCB development, motor selection, vibration optimization, waterproof engineering, and testing protocols. Since toothbrushes operate in humid environments, waterproof integrity is crucial. Therefore, professional factories implement ultrasonic sealing processes and strict IPX7/IPX8 verification.

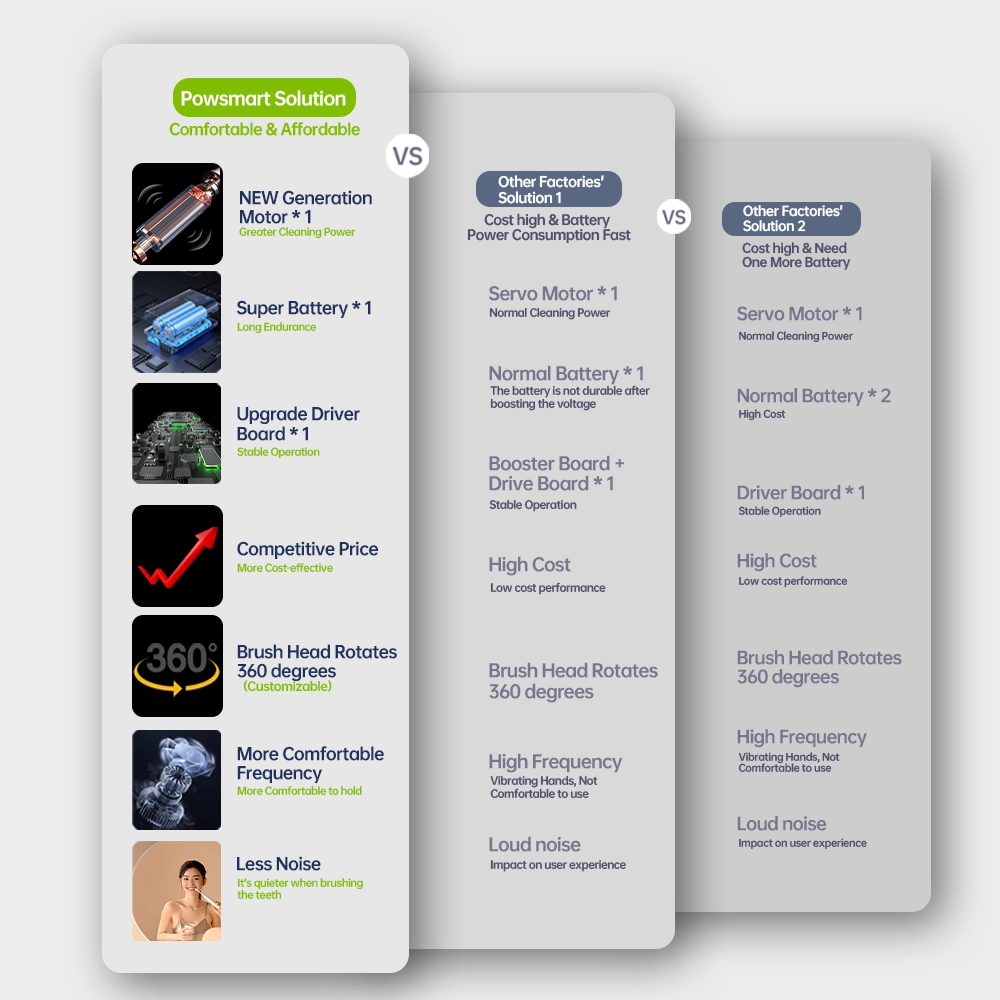

Additionally, strong factories also optimize noise performance, motor lifespan, and brushing-mode algorithms. These engineering capabilities allow brands to establish higher product positioning and meet regional compliance requirements.

Check more OEM-ready components on:

https://powsmart.com/oem-electric-toothbrush

OEM projects often require custom handle shapes, LED layouts, and surface-treatment options. A factory with comprehensive design capabilities allows buyers to create products that reflect brand aesthetics without requiring major technical adjustments. Furthermore, experienced suppliers maintain ID design libraries that accelerate development cycles and ensure compliance with internal structural layouts.

Design flexibility also extends to packaging. Since packaging affects retail visual impact, especially in Europe and the U.S., OEM suppliers often provide dielines and carton templates for quick adaptation.

Production capacity remains a major decision factor in selecting OEM partners. Automated bristle-planting, SMT lines, and intelligent assembly stations ensure consistency and reduce quality variations. For global brands preparing retail launches, this stability directly affects order planning and supply-chain predictability.

Because international buyers often require multiple brushing modes, stable PCB programming and vibration consistency become key. Factories with complete testing stations ensure every item meets performance standards before shipping.

You may consult additional certification references on:

https://www.ada.org

When selecting an OEM partner, long-term technical support matters. Whether adjusting motor performance or upgrading battery technology, a strong supplier offers sustained engineering assistance. This stability allows distributors to continuously update their product portfolio and maintain competitive advantage.

To remain competitive, brands must collaborate with suppliers that demonstrate strong electric toothbrush OEM capabilities, from engineering design to automated manufacturing and compliance support.

.jpg)

Which Electric Toothbrush Is Best for College Students in Boston?

.jpg)

Noise Complaints from Handle Corrosion? A Silent Threat Uncovered!

.jpg)

Children’s Smart Toothbrush | OEM Solutions for Pediatric Oral-Care Brands

.jpg)

Seal Degradation Plus Circuit Shorting – Safety Risk?

.jpg)

Benefits of Travel-Friendly Water Flosser Design

.jpg)

How to support dental charity? Free clinics in Kirkland

.jpg)

Electric Toothbrush for Clinics Europe – Professional Oral-Care Supply

Why Is a Dependable Toothbrush Battery Supplier Crucial for a Long-Lasting Toothbrush?

Analysis of the Core Components of Electric Toothbrush: How Do High-Performance Motors Improve Cleaning Efficiency?

Ensuring Long-Term Quality: How to Prevent Mold in Electric Toothbrush Handles

Electric Toothbrush Wholesale Market Analysis: Some of the Best-Selling Models in 2025

.jpg)

Silent Sonic Toothbrush Manufacturer

What Impact Will There Be If Only the Cost-Effectiveness of Price Is Considered When Sourcing Oral Care Products?

.jpg)

Electric Toothbrush Troubleshooting Flowchart: A Practical OEM Guide for Brands

.jpg)

Does Your Brush Fight Plaque Smartly?

Preventing Water Damage in Electric Toothbrush Charging Ports: A Manufacturing Perspective