As the demand for teeth whitening products continues to rise, businesses seeking to enter the market often turn to OEM (Original Equipment Manufacturer) solutions. The Teeth whitening device OEM process allows brands to create customized products without investing in their own manufacturing facilities. In this guide, we will walk through the entire process, from initial design to final mass production, and explore the benefits of ODM/OEM cooperation with a reliable teeth whitening products factory.

Before initiating an OEM project, thorough market research is essential. Understanding customer preferences, market trends, and competitive landscape ensures that your teeth whitening device meets consumer needs. Collaborating with an experienced teeth whitening products factory at this stage can provide insights into viable product features and design considerations.

Once the concept is finalized, the next step involves creating a design blueprint. This includes:

Device shape and ergonomic considerations

Material selection for safety and durability

Functional components such as LED lights, power sources, and whitening gel compatibility

Manufacturers specializing in the Teeth whitening device OEM process will assist in prototyping, enabling you to test design feasibility before committing to mass production.

Quality assurance is crucial in the teeth whitening industry. Before moving to mass production, the prototype undergoes rigorous testing, including:

Performance testing for efficacy and durability

Safety testing to meet regulatory requirements (e.g., FDA, CE, RoHS)

Compliance with international standards for electronic and cosmetic devices

Collaborating with an experienced ODM/OEM cooperation partner ensures your product meets all necessary legal and quality benchmarks.

Once the prototype passes all necessary tests, production preparation begins. This stage involves:

Creating molds and tooling for device components

Setting up production lines

Ensuring a stable supply chain for materials

A professional teeth whitening products factory ensures streamlined production setup, minimizing costs and lead time.

With production lines ready, mass manufacturing begins. The key elements in this stage include:

Assembling components with precision

Conducting multiple quality control checks at different production stages

Implementing batch testing to ensure consistency

Partnering with an experienced Teeth whitening device OEM process manufacturer guarantees efficiency and high-quality output.

Finalizing packaging design is essential for brand identity and customer appeal. At this stage:

Custom packaging is developed to align with branding

Compliance with shipping regulations is ensured

Logistics and distribution planning is executed for seamless market entry

A reliable teeth whitening products factory will often provide packaging solutions to optimize shipping costs and product presentation.

The Teeth whitening device OEM process provides businesses with an efficient way to launch innovative products. By working closely with an experienced ODM/OEM cooperation partner, brands can ensure a smooth journey from concept to mass production. Choosing the right teeth whitening products factory is crucial to achieving high-quality results, regulatory compliance, and successful market penetration.

If you’re looking for a trusted partner to bring your teeth whitening device to life, contact us today to explore customized OEM/ODM solutions tailored to your business needs!https://www.powsmart.com/contact-us/

New Technical Possibilities for Wireless Teeth Whitening Devices

.jpg)

Wireless Inductive Charging Polishing Electric Toothbrush manufacturers

The Science of Light: How Red & Blue LED Technology Enhances Modern Oral Care

.jpg)

Child Compatibility Meets Cold Light Sensitivity: Safe?

Case Study of Intelligent Upgrading of Dental Instrument Factory

Mitigating LED Teeth Whitening Side Effects Through OEM Design & Formulation

Do At-Home Light Therapy Teeth Whiteners Really Work?

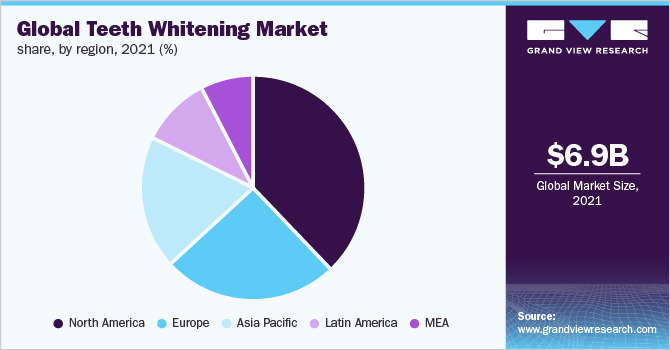

Analysis of Differences in Preferences for Teeth Whitening Devices in the European and American Markets vs. Asian Markets

.jpg)

Smart Toothbrush India | Modern Oral Care Solutions

Five Key Points in Quality Control of Blue Light Teeth Whitening Device: How to Ensure LOW Defects in Products?

The Market is Growing Rapidly: Is There Still an Opportunity to Enter the Oral Irrigator Industry?

.jpg)

Sync Errors Causing Taste Distortion – Tech Glitch?

.jpg)

powsmart electric toothbrush factory

Is Blue Light Under 480nm Safe for Teeth Whitening Devices?

How Does a Photobleaching Catalyst Interact with Optical Brighteners in Advanced Whitening Formulations?

Teeth whitening device OEM: In-Depth Cooperation Model from LOGO to Light Wave Customization