In modern oral care manufacturing, performance and safety must evolve together. Selecting Food-grade Bristle Material from a trusted Micro Motor Supplier ensures that brush heads are engineered not only for effective cleaning, but also for material safety, mechanical compatibility, and long-term product reliability in high-frequency motor-driven systems.

Food-grade bristle materials are designed to meet strict safety standards for oral contact, while also withstanding the dynamic forces generated by micro motors. A qualified Micro Motor Supplier understands how bristle flexibility, resilience, and fatigue resistance interact with motor vibration and rotational speed.

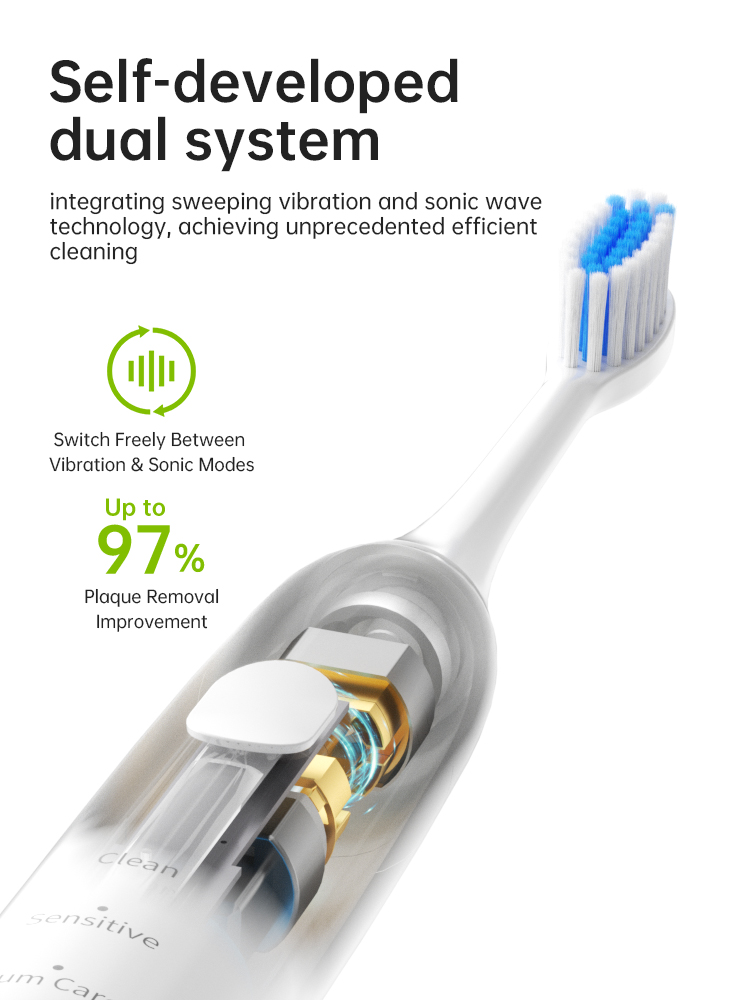

The efficiency of a brush head depends on how well bristles respond to motor-generated motion. When Food-grade Bristle Material is sourced through a Micro Motor Supplier, bristle stiffness and filament geometry can be matched precisely to motor torque and frequency for optimal plaque removal.

High-speed micro motors can accelerate bristle wear if materials poorly matched. Trusted suppliers select Food-grade Bristle Material with proven abrasion resistance and elastic recovery, helping maintain consistent brushing performance throughout the recommended replacement cycle.

A reliable Micro Motor Supplier typically works with standardized injection molding and tufting processes. This ensures that Food-grade Bristle Material integrates smoothly into automated production lines, reducing defects, variation, and downstream assembly issues.

Food-grade Bristle Material sourced through an experienced supplier supports compliance with FDA, EU, and other international safety frameworks. A knowledgeable Micro Motor Supplier helps align material documentation, testing protocols, and traceability requirements for multi-market distribution.

Beyond component sourcing, a trusted Micro Motor Supplier often provides system-level insights. This includes guidance on how Food-grade Bristle affects noise levels, vibration transmission, and overall user comfort in motor-driven oral care devices.

Choosing Food-grade Bristle from a trusted Micro Motor Supplier is a strategic decision that balances safety, performance, and manufacturability. By aligning material science with motor engineering, brands can deliver durable, compliant, and high-performing oral care products that stand out in competitive markets. Contact us

Can a Wireless Charging Coil Maximize the Efficiency of a Lithium Battery Pack in Electric Toothbrushes?

Can a California whitening brush protect California sensitive teeth?

How Does Packaging Customization Service Enhance the Appeal of Products with UV Sanitizing Component?

Teeth whitening kit manufacturers

.jpg)

Waterproof Sonic Toothbrush Manufacturer

Can a Portable Water Flosser incorporate elements of Desktop Irrigator Design for versatility?

Do I Need FDA Approval to Sell Household Teeth Whitening Products?

-1-scaled.png)

Teeth Whitening Gel Manufacturer

.jpg)

California electric toothbrush wholesaler

What Safety Regulations in Local Laws Need to Be Met for the Sale of Teeth-Whitening Product Ingredients in the United States?

.jpg)

Wireless Teeth Whitening Kit | Cord-Free LED Oral Beauty System for modern beauty and oral-care OEM brands.

Are At-Home Teeth Whitening Kits Safe for Long-Term Use? An OEM Analysis

Top 10 California electric toothbrush factory for OEM/ODM Services

.jpg)

Electric Toothbrush Supplier California

.jpg)

Wireless Inductive Charging Whitening Electric Toothbrush manufacturers

.jpg)

best electric toothbrush for sensitive teeth