In today’s competitive market, toothbrush manufacturing equipment plays a crucial role in ensuring that toothbrushes meet high standards. When combined with strict production processes, this equipment is essential for obtaining toothbrush quality certification. In this blog, we will explore how advanced manufacturing technology ensures your toothbrush products are certified for quality.

Advanced toothbrush manufacturing equipment allows for precise control over the production process. This includes accurate bristle placement, handle shaping, and the alignment of all parts. Precision is critical to meet the requirements of toothbrush quality certification, ensuring that every toothbrush is identical and functions as expected, maintaining high standards across all units.

With the rise of automated production lines, toothbrush manufacturing equipment can now monitor and control every aspect of production. Automated systems can detect defects in real time, minimizing human error and ensuring that each toothbrush meets the necessary specifications. This consistent quality control is vital for passing toothbrush quality certification processes.

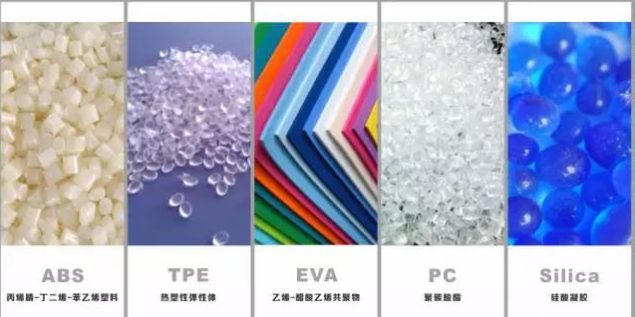

Advanced manufacturing equipment allows manufacturers to use high-quality, certified materials, ensuring that each toothbrush is durable, safe, and effective. The equipment helps manage the consistent blending and handling of materials like nylon bristles and plastic handles. By ensuring the correct material composition, the toothbrush quality certification process becomes smoother and more reliable.

Modern toothbrush manufacturing equipment often includes integrated testing mechanisms that simulate real-world use. These testing systems can check the bristle strength, handle flexibility, and overall durability of the toothbrush. This advanced testing ensures that every batch is subjected to the same rigorous standards, which is essential for securing toothbrush quality certification.

For a toothbrush to obtain toothbrush quality certification, it must meet regulatory requirements set by agencies such as the FDA or ISO. Advanced toothbrush manufacturing equipment is designed to adhere to these regulations by ensuring that production is conducted in controlled, clean environments. This compliance ensures that all manufactured toothbrushes meet the necessary safety and quality standards.

Many manufacturers are incorporating environmentally friendly practices into their production lines. Advanced toothbrush manufacturing equipment can be optimized to reduce waste and energy consumption. This sustainability is an important aspect of modern quality certifications, as agencies are increasingly prioritizing environmental impact alongside product quality.

Advanced toothbrush manufacturing is critical in ensuring that toothbrushes meet rigorous toothbrush quality certification standards. By providing precision, automation, and robust testing, this equipment ensures that each product is safe, durable, and effective. Manufacturers who invest in such technology are more likely to meet quality certification requirements, gain customer trust, and maintain a competitive edge in the market. Contact us

.jpg)

Brooklyn Fast Local Delivery Electric Toothbrush Wholesale Suppliers

Electric toothbrushes: personalized oral care solutions

How to Find an Electric Toothbrush Factory with Strong Comprehensive Capabilities

Life Expectancy of an Electric Toothbrush: OEM Quality Considerations

Which Electric Toothbrush Shell Material is More Durable?

.jpg)

.jpg)

Why Is Smart Toothbrush APP Development Crucial for Rechargeable Toothbrush Battery Optimization?

Light Teeth Whitening: How It Works & Is It Safe?

.jpg)

Washington Hygienist Recommended Toothbrush Distributor

.jpg)

OEM Sonic Toothbrush Manufacturer China | Custom Oral Care Production

.jpg)

Gentle Oral Care Products for Sensitive Gums: A Guide for Brands Seeking the Right Manufacturer

.jpg)

How Does Allergen Testing Prevent Bleach Residuals?

.jpg)

How Does a Water Flosser Nozzle Manufacturer Support an Orthodontic Water Flosser OEM for Specialized Care?

.jpg)

Are Runtime Drop and Thermal Failure Related?

.jpg)

Chicago holiday deals on a Chicago subscription toothbrush — worth it?

Can a Delhi student toothbrush be quality under a Rupees 1500 toothbrush price point?