In professional oral care manufacturing, preventing enamel scratching during device use is a critical design and quality concern. Increasing evidence shows that tooth porosity—whether natural or treatment-induced—can significantly elevate the risk of enamel abrasion when using mechanical cleaning devices like sonic toothbrushes or whitening applicators. But once enamel is scratched, is the damage truly irreversible? Understanding the interaction between tooth porosity and surface wear helps manufacturers design safer, more consumer-trusted products.

Tooth porosity refers to microscopic pores or structural irregularities in enamel, resulting from:

Porous enamel lacks the uniform hardness of healthy enamel. This makes it more prone to enamel scratching during mechanical brushing, especially with stiff bristles or aggressive polishing heads.

Scratching doesn’t mean deep cuts—it refers to microabrasions at the enamel surface level:

These scratches compromise enamel’s natural smoothness and reflective properties, eventually making teeth appear darker or rough. Company web:https://www.powsmart.com/product/electric-toothbrush/

Unlike soft tissue injuries, enamel scratching cannot self-repair:

Thus, once significant enamel scratching has occurred, the damage is functionally irreversible—making prevention the only real solution.

Manufacturers can protect against enamel scratching, even on porous teeth, through:

These measures help minimize mechanical aggression on enamel, addressing varying tooth porosity across different users.

Effective product validation requires:

By testing devices under varied porosity conditions, manufacturers can proactively mitigate scratching risks before market release.

By addressing enamel scratching risk upfront, brands can:

In sensitive oral care markets, safety-driven design is no longer optional—it’s a competitive differentiator.

So, is enamel scratching from tooth porosity irreversible? In most cases, yes. This makes preventive design and testing critical for manufacturers of oral care devices. By understanding how porosity amplifies abrasion risks and applying targeted design protections, OEM and ODM suppliers can deliver devices that safeguard both aesthetics and long-term dental health. Contact us

.jpg)

.jpg)

Dentistry Instrument Factory Market Trends and Customized Production Solutions

How Does Blue LED Technology in Whitening Ensure Gum Protection?

.jpg)

Multi-Mode Electric Toothbrush Manufacturer for OEM Oral Care Projects

Introduction of 5 Important Teeth Whitening Products in Oral Care and Their Pros and Cons

How does a Pressure-sensitive Matrix leverage Hydro-kinetic Energy Transfer for gentle cleaning?

.jpg)

Powsmart-Soft Bristle Electric Toothbrush OEM Manufacturer for Sensitive Care

.jpg)

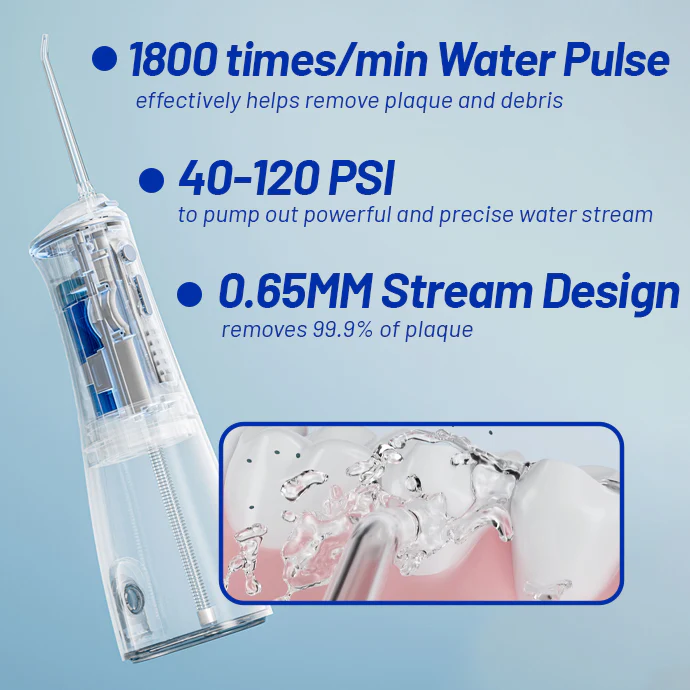

Solutions for Water Flosser Having Unstable and Intermittent Water Flow

Electric Toothbrush Manufacturing Process

.jpg)

Teeth Whitening Device Compliance in the EU Market: A Guide for OEM Buyers

Can a Wireless Whitening Kit Integrate Foam from a Teeth Whitening Foam Manufacturer for Innovation?

.jpg)

Oral Care Product OEM Manufacturer for Private Label Brands

.jpg)

Corporate Gift Supplier Alabama Dental | Custom Oral Care

.jpg)

Home-Use Whitening Lamp OEM | Custom LED Dental Light Manufacturer

.jpg)

Battery Corrosion + Charger Incompatibility — What’s Next?

.jpg)

Is an RV battery toothbrush truly an RV travel essential?