Plaque is the biofilm that underpins most common oral-health problems, and therefore product teams and channel partners care deeply about which toothbrush features actually reduce it. For B2B buyers — distributors, dental clinics and OEM partners — understanding the engineering and behavioral levers that drive plaque reduction helps you specify better products, reduce returns, and improve end-user satisfaction. Below are six evidence-informed factors to prioritize when designing or sourcing an electric toothbrush that truly fights plaque.

First and foremost, the physical interface matters. A compact brush head with appropriately tapered, end-rounded soft bristles reaches the gingival margin and posterior areas more effectively than a bulky head. Moreover, mixed-length bristle patterns (filament tiers or angled “cross-action” clusters) dislodge biofilm mechanically by entering fissures and interproximal gaps. Consequently, specifying head geometry and filament stiffness in the BOM is one of the highest-leverage design choices for plaque removal.

Next, the motor and the motion it creates determine how plaque is disrupted. Oscillating-rotating action cleans by sweeping and scrubbing, while high-frequency sonic vibration creates fluid dynamics that flush biofilm from crevices. Therefore, choose a motor and transmission tuned for consistent amplitude and frequency; additionally, optimize brush-to-tooth contact time (strokes per second or VPM) rather than raw power alone, because controlled motion with good bristle-to-surface engagement is what removes plaque efficiently.

Furthermore, user behavior is crucial: inadequate time or uneven coverage leaves plaque behind. Hence, embedding a reliable 2-minute timer with a Quadpacer interval — plus targeted modes such as “Deep Clean” and “Gum Care” — nudges users to evenly clean all quadrants and apply appropriate intensity where plaque accumulates. For B2B customers, highlighting timer and mode design in specs helps differentiate devices on clinical outcome potential.

In addition, excessive force both damages tissue and paradoxically reduces effective plaque removal by flattening bristles. Integrating a pressure-sensor (mechanical or electronic) that provides haptic, visual, or audible feedback helps users correct technique and maintain effective contact without over-brushing. In other words, pressure control protects gums while enabling the brush to target and remove plaque optimally.

Moreover, worn bristles lose cleaning efficiency. Therefore, define expected bristle life (commonly ~3 months), incorporate visible indicators (color-fade filaments or app reminders), and support an easy replacement program. From a commercial standpoint, well-engineered replacement heads both sustain plaque-removal performance and create recurring aftermarket value for B2B channels.

Finally, hygiene of the brush itself affects long-term plaque control. Waterproofing (e.g., IPX ratings), non-porous antimicrobial housings, and optional UV or ozone sanitization for brush-head docks reduce microbial load between uses. Consequently, selecting durable materials and serviceable designs reduces contamination risk and preserves cleaning performance over the product lifetime.

Conclusion (short):

To summarize, an effective toothbrush for fighting plaque is the product of considered hardware, smart electronics, and behavior-shaping features. In practice, manufacturers who combine optimized head geometry, a proven motion profile, timers/modes, pressure control, robust replacement systems, and hygienic materials will deliver the best outcomes for end users — and the strongest commercial proposition for B2B partners.

6-point action checklist for manufacturers & B2B buyers:

Medical note: This article speaks to product design and user behavior. For persistent plaque, advanced periodontal issues, or clinical questions, recommend that end users seek professional dental care. Contact us

.jpg)

-1024x1024.jpg)

.jpg)

Rechargeable Oral Care Kit Supplier | Complete OEM/ODM Solutions

The Market Prospect of Children Electric Toothbrush

Does Black Electric Toothbrush ODM Face Handle Corrosion?

.jpg)

Portable LED Teeth Whitening Device Supplier

Electric Toothbrush Head Customization Solution and Range

UV Sanitizing Toothbrush Holder OEM: Hygienic Oral Care Accessories

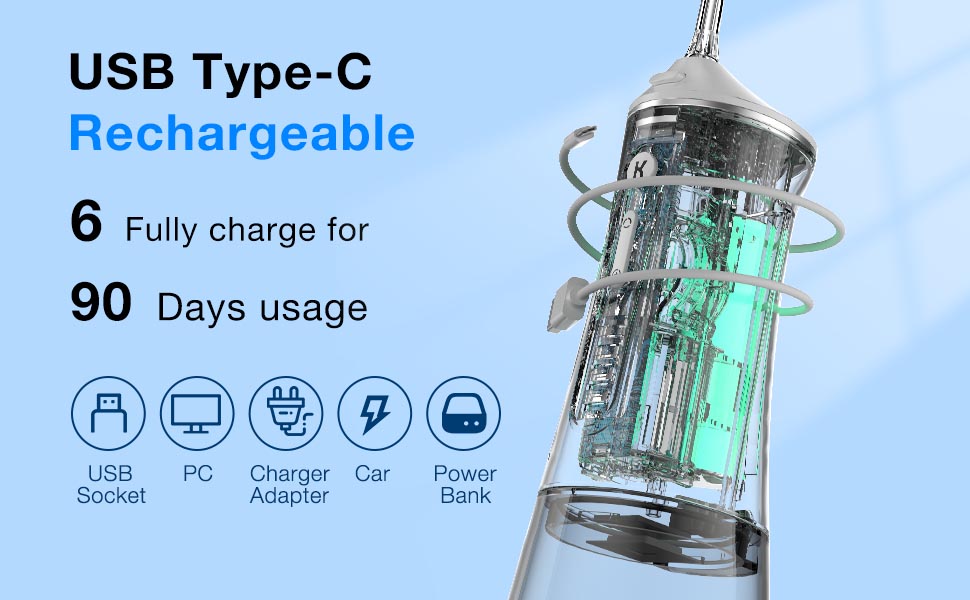

Wireless Water Flosser Production Guide: The Perfect Match Between Lithium Battery and Water Pump

Some Common Charging Problems of Electric Toothbrushes and Solutions from the Electric Toothbrush Factory

.jpg)

Seal Degradation Plus Circuit Shorting – Safety Risk?

.jpg)

ADA-Style Toothbrush Supplier China for OEM & Private Label Brands

Tips for Preventing Mold in Water Flosser Tanks

.jpg)

Water Dispersion plus Jet Scattering – Fixable?

Where to Find Electric Toothbrush Sales in Dallas?

.jpg)

Electric Toothbrush for Wellness Subscription Boxes – OEM/ODM Supply Guide

.jpg)

Before or After Brushing? Solving the Water Flosser Sequence for Your OEM Brand

Technical R&D and production capacity of the factory