In the electric toothbrush OEM business, controlling production costs is crucial to staying competitive. Among various expenses, mold cost is often one of the highest upfront investments. Many manufacturers have developed an electric toothbrush mold library, offering ready-made solutions that significantly shorten the mold opening cycle and reduce costs. But exactly how much money can be saved by using an existing mold? Let’s dive deeper.

An electric toothbrush mold library is a collection of pre-existing injection molds covering various designs of toothbrush handles, brush heads, and chargers. These molds are production-ready and meet common industry standards.

By leveraging these existing resources, OEM clients can:

Avoid the lengthy and costly mold development process

Accelerate time-to-market

Reduce risks associated with new product tooling

Typically, creating a new mold (from design to production) involves a mold opening cycle of 45 to 90 days, depending on complexity. This timeline includes:

Industrial design and structural optimization

Mold fabrication and testing

Correction and final approval

In contrast, using ready-made mold modification (such as minor logo engraving, color changes, or slight structure adjustments) can be completed within 2 to 4 weeks — drastically reducing project lead time.

The financial advantages are very clear:

| Category | New Mold Development | Ready-Made Mold Modification |

| Mold Cost | $8,000–$30,000+ | $500–$2,000 (modification fee) |

| Mold Opening Cycle | 45–90 days | 14–30 days |

| Risk of Redesign | High | Low |

In some cases, choosing a suitable mold from the electric toothbrush mold library can save up to 90% of the traditional mold cost!

OEM brands can optimize their budgeting by creating a smart cost control plan. Here’s how:

Prioritize product requirements: Determine if functional innovation is needed, or if appearance customization is enough.

Consult with suppliers early: Ask about available options in their electric toothbrush mold library.

Customize through modification: Use ready-made mold modification strategies to align with branding needs (logo, colors, surface texture).

Plan inventory scaling: With reduced upfront costs, allocate more budget to marketing or scaling production.

This approach ensures a more agile and financially sustainable launch.

Choosing to use an existing electric toothbrush mold library is a highly effective strategy to:

Shorten the mold opening cycle

Control the mold cost

Accelerate time-to-market

Minimize technical risks

By working with experienced manufacturers who offer ready-made mold modification services and providing a transparent cost control plan, OEM clients can launch high-quality electric toothbrush products faster and with much lower financial pressure.

Contact our team today to explore our full mold library and find the most cost-effective solution for your next OEM project!

Confused About the Multiple Flossing Options of the Water Flosser? Here’s How to Choose the Right One

.jpg)

Over-Bleaching Effects from Whitening Effectiveness Claims?

.jpg)

Child Compatibility Meets Cold Light Sensitivity: Safe?

Key Process Traceability of Electric Toothbrushes: Quality Inspection Record Management of Motor Calibration and Waterproof Testing

Why Does the Oral Irrigator Make Abnormal Noise After Being Used for a Period of Time?

.jpg)

A Complete Guide to OEM Customization of Electric Toothbrushes: From LOGO Printing to Core Function Development

ISO 13485 Certification Interpretation: How Do Electric Toothbrush Meet Medical Device-Grade Production Standards?

.jpg)

Does Your Brush Fight Plaque Smartly?

.jpg)

What’s the Best Electric Toothbrush for Outdoor Enthusiasts in Colorado?

.jpg)

Why Dentin Exposure Risk with UV Light Risks?

A Must-Have Guide for Brands to Deal with Water Leakage, Unstable Pressure, and charging failure repair of Water Flosser

.jpg)

Hydrogen Peroxide Concentration & Motor Durability: Linked?

.jpg)

sonic electric toothbrush Colorado Springs

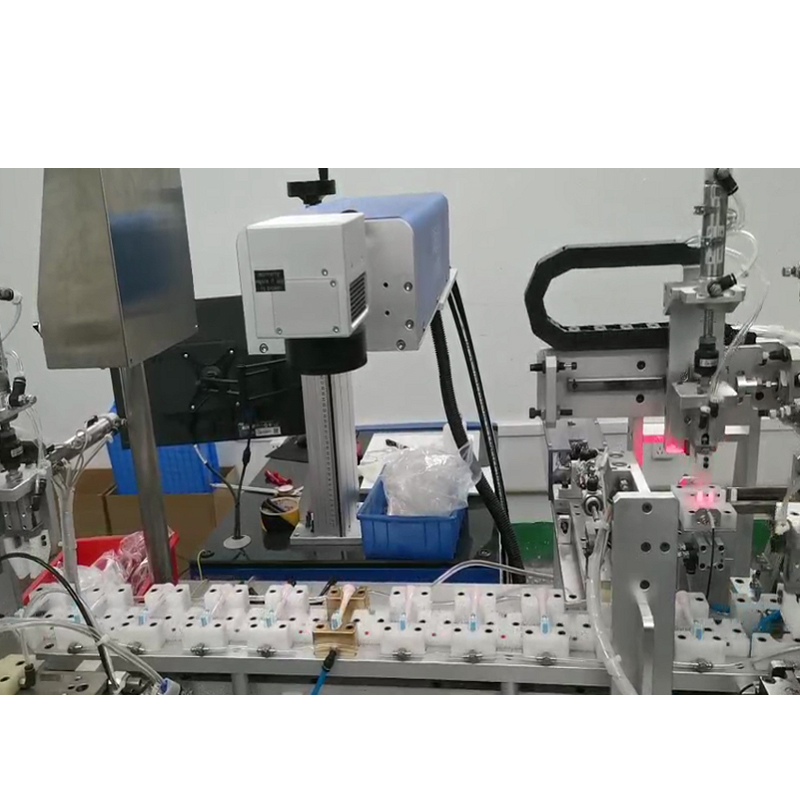

Electric Toothbrush Production Process Diagram: Complete Process from Injection Molding to Assembly and Key Points of Quality Inspection

How to Control the Life of Key Components of Water Flosser and Reduce the After-Sales Rate?

.jpg)

Charging Time Efficiency & Oral pH Alteration: A Subtle Link?