Many manufacturers of rechargeable devices are noticing a recurring issue during product usage: a gradual runtime shortening even when the battery is not yet at the end of its cycle life. One frequently suspected cause is battery memory — a phenomenon often misunderstood or overlooked. But are these two issues truly connected? This blog explores the relationship between runtime degradation and memory effect, and provides insights on how manufacturers can address this potential performance risk through informed design and quality control.

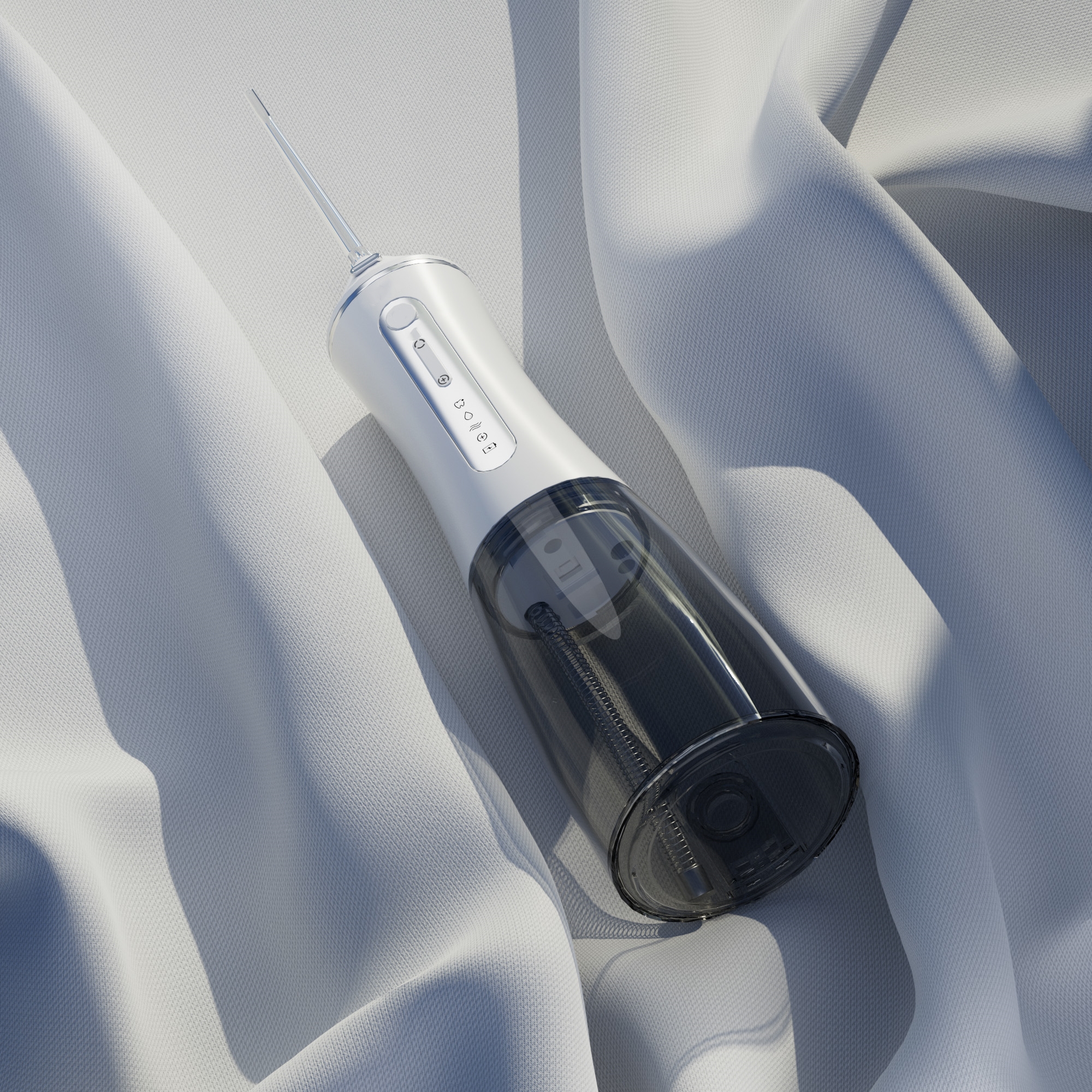

Runtime shortening refers to a device’s decreasing ability to maintain its intended performance duration after a full charge. In the context of electric toothbrushes, water flossers, or whitening systems, this means less cleaning time or lower motor efficiency—both of which can negatively impact the end-user experience. While aging batteries are a common culprit, devices with relatively new battery packs have also exhibited runtime drops, prompting further technical analysis. Company web: https://www.powsmart.com/product/electric-toothbrush/

Battery memory (also known as the memory effect) is a condition historically associated with nickel-cadmium (NiCd) batteries, wherein the battery “remembers” a shorter discharge cycle if it’s repeatedly recharged without full depletion. Over time, this partial charging habit can lead to a reduced usable capacity, as the battery stops delivering its full power range. While modern lithium-ion batteries are less susceptible to this effect, improper charging protocols and poor battery management systems can still cause similar behavior, contributing indirectly to runtime shortening.

The relevance of battery memory in today’s battery-powered devices depends heavily on the battery chemistry and charging patterns. While lithium-ion and lithium-polymer cells dominate current portable medical and personal care devices, these chemistries are not completely immune to charge cycle-related degradation. Suboptimal firmware or BMS (battery management system) algorithms can mimic memory-like symptoms by recalibrating charge thresholds inaccurately, resulting in premature cut-off points and reduced runtime, giving the impression of runtime shortening without actual battery damage.

Manufacturers must consider that runtime shortening is often a combined result of both hardware and software factors. A well-designed BMS should monitor voltage, temperature, charge cycles, and discharge rates, adapting in real time to preserve battery health. However, if operators do not properly tune these systems, they may allow early termination of discharge cycles or incorrect state-of-charge readings, both of which contribute to shorter perceived runtimes. Furthermore, frequent partial charges without periodic full discharge calibrations can reinforce false capacity readings—again, resembling the battery memory issue.

To avoid unexpected runtime shortening, manufacturers should implement the following preventive strategies during product development:

These measures collectively minimize performance drift and help separate actual battery degradation from behavior-induced issues like battery memory.

So, is runtime shortening related to battery memory? The answer is: it can be — but not always in the traditional sense. While classical battery memory effects are rare in modern lithium systems, user behavior, flawed battery management systems, and improper calibration can still simulate similar symptoms. For OEMs and device brands, understanding this nuanced relationship is key to preventing premature complaints, reducing warranty costs, and improving customer satisfaction.

By designing smarter, monitoring better, and educating users, manufacturers can ensure long-lasting runtime performance—and leave memory issues in the past where they belong. Contact us

Electric Toothbrush Inspection and Quality Control in China

.jpg)

Teeth Whitener Light Control & Weld Line Removal: Enhancing Aesthetics and Performance

.jpg)

Whitening Pen + LED Kit Supplier | Teeth Whitening Combo OEM

.jpg)

Can an Austin eco toothbrush double as an Austin whitening brush?

What Are the Advantages of Home Dental Beauty Products?

.jpg)

Teeth Whitening Device Tooling Cost — What B2B Buyers Should Plan For

.jpg)

USB-C Charging Electric Toothbrush OEM

.jpg)

Waterproof Sonic Toothbrush for Spas | Professional LED Oral Care Devices

Why Is It Important to Use a Water Flosser Instead of Dental Floss?

.jpg)

How to Stand Out in Dallas Electric Toothbrush Wholesale Market

Travel Water Flosser Design: Power Compatibility, Storage & Waterproofing

Does Jet Stream Precision Depend on Long-Term Hose Durability?

How to Enhance Brand Competitiveness by Segmenting the Market Demand for Teeth Whitening

Why Is Universal Brush Head Compatibility a Challenge for Certification Compliance?

Can the Elderly Use Electric Toothbrushes?

.jpg)

Long Island deals for NYC waterproof brush — pool-safe?