In the realm of medical and personal care devices, ensuring Electromagnetic Compatibility (EMC) Compliance and effective Thermal Suppression in Oral Irrigators is paramount. Adherence to industry standards minimizes electromagnetic interference and enhances device stability, preventing overheating that could damage electronic components or degrade user experience. This article delves into strategies for integrating precise design and advanced technologies to achieve EMC compliance while optimizing thermal management in oral irrigators.

EMC compliance is a fundamental requirement for all electronic products, including oral irrigators, to be legally sold in the market. EMC testing ensures that devices do not emit excessive electromagnetic interference (EMI) and are immune to external electromagnetic disturbances.

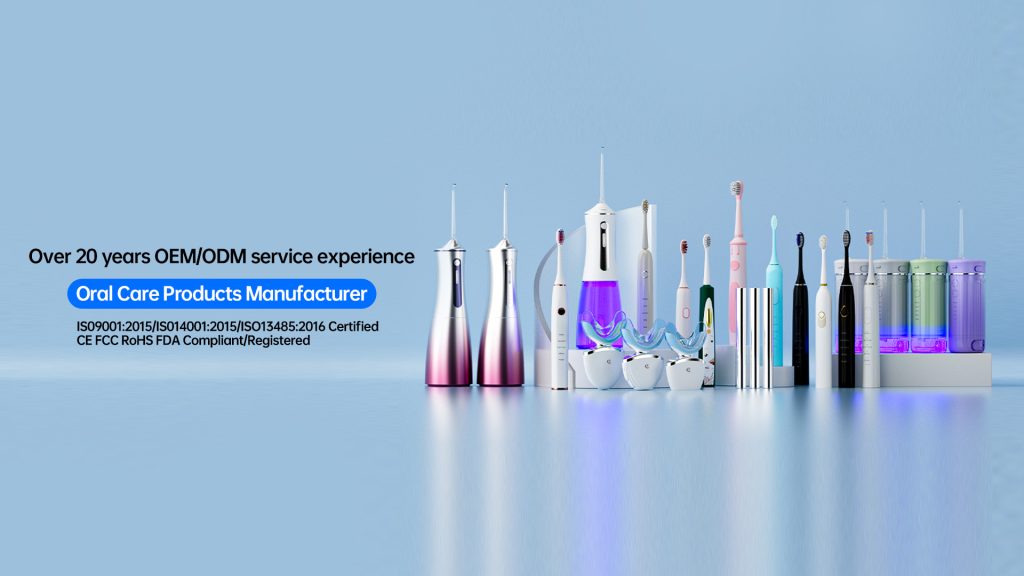

To meet EMC standards such as FCC, CE, and IEC 60601-1-2, manufacturers should incorporate appropriate shielding, filtering, and grounding techniques during the research and development phase.

When undergoing EMC testing, oral irrigators face several challenges:

Solutions include optimizing circuit layouts, employing appropriate filtering circuits, adding shielding materials, and conducting rigorous EMC testing to ensure compliance.

Beyond electromagnetic compatibility, thermal management is a critical aspect of oral irrigator design. The integration of motors, heating elements (in some models), and control circuits can lead to heat accumulation, potentially affecting product lifespan and performance.

Implementing these measures ensures that oral irrigators operate efficiently while maintaining low temperatures, thereby enhancing user experience and product longevity.

EMC compliance and thermal management often influence each other; optimizing one aspect may impact the other. Therefore, a balanced approach is essential during the design process:

Through systematic optimization strategies, manufacturers can ensure EMC compliance while maintaining effective thermal management performance.

Various markets impose different regulatory requirements for EMC and thermal management. Key testing standards include:

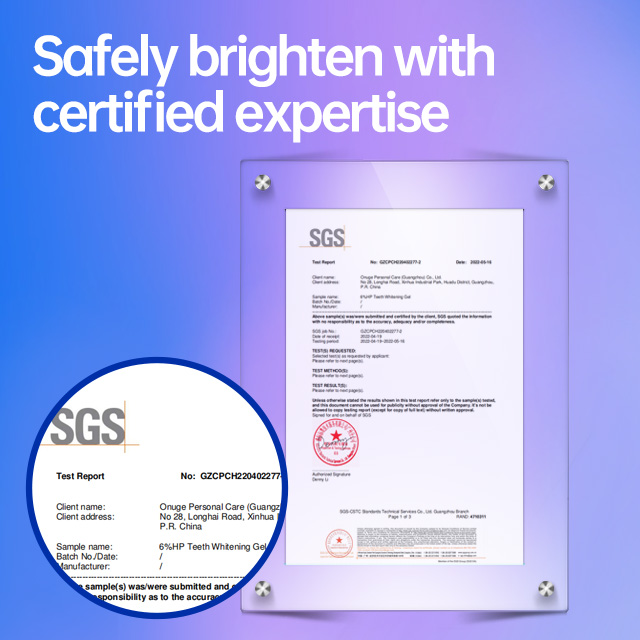

Manufacturers must ensure products comply with target market standards and undergo testing by third-party certification bodies to facilitate market entry.

As the oral care industry evolves, advancements in EMC compliance and thermal suppression technologies continue to emerge. Future trends include:

Continuous innovation enables manufacturers to improve product reliability and strengthen market competitiveness.

In the design and production of oral irrigators, EMC compliance and thermal suppression are critical factors. By implementing appropriate circuit designs, shielding techniques, thermal solutions, and rigorous testing and compliance certifications, manufacturers can ensure product safety, stability, and alignment with market demands.

If your enterprise seeks to optimize EMC and thermal management solutions for oral irrigators, our team offers professional support. https://www.powsmart.com/contact-us/

.jpg)

multi mode electric toothbrush OEM | Customized Sonic Toothbrush Manufacturer

.jpg)

Gentle Electric Toothbrush for Sensitive Aging Gums

Why Pair Custom Teeth Whitening Tray Services with a Teeth Whitening Pen Manufacturer for Diverse Options?

Oral irrigator sourcing tips

.jpg)

Is the tongue cleaner on the back of the toothbrush useful?

.jpg)

Orthodontic Care Electric Toothbrush OEM

Do You Have to Charge a Water Flosser for 24 Hours? OEM Fact Check

.jpg)

SF Toothbrush Deals: Factory-Direct Discounts from China to San Francisco

How to Select the Right Tip for a Water Flossing Device?

Can Pulse Frequency Control Be Achieved Without Compromising a Quiet Operation Motor?

Cheap vs High-End Electric Toothbrushes : 5 Key Differences You Should Know

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8 for Humid Climates

Enamel-Safe Whitening: OEM Products That Brighten Smiles Without Harm

How to Effectively Reduce the After-Sales Return Rate of Electric Toothbrushes

Can Intelligent Electric Toothbrushes Keep Evolving Like Mobile Phones?

How Do Surface Reflectance and Subsurface Scattering Measurements Improve Whitening Efficacy Evaluation?