In daily industrial operations, Hose Blockages and Motor Overheating often emerge as major challenges that can lead to equipment failures. In systems such as hydraulic or cooling systems, a blockage in the hose can restrict the smooth circulation of fluids, while an overheated motor may suffer from inadequate cooling and diminished longevity. This blog explores the root causes behind these issues, explains how they interact with each other, and provides a range of strategies for quickly diagnosing and resolving these problems to enhance equipment stability and prolong its operational life.

When hose blockages occur alongside motor overheating, device performance takes a significant hit. Blocked hoses impede the flow of cooling or lubricating fluids, which in turn leads to rapid temperature rises in the motor. This can trigger a cycle where the motor, already compromised by heat, further accelerates wear on the hose. The combined effect disrupts production, increases maintenance costs, and can negatively impact a brand’s reputation if left unresolved.

Hose blockages can result from several factors:

Identifying these issues early is critical to preventing system-wide failures.

Motor overheating is commonly caused by:

When a motor overheats, its performance degrades, potentially shortening the overall lifespan of the equipment.

The connection between hose blockages and motor overheating is both direct and compounded:

Understanding this interaction is vital to implementing effective mitigation measures.

To promptly address the combined issues of hose blockages and motor overheating, consider the following strategies:

Looking forward, the integration of smart, predictive maintenance solutions will become increasingly important. Future innovations may include:

By embracing these new technologies and maintaining robust quality management practices, companies can not only resolve existing issues faster but also prevent similar problems from recurring, ensuring long-term operational stability.

Conclusion

When hose blockages meet motor overheating, the resulting disruptions can severely hinder equipment performance and lead to increased downtime. However, by understanding the root causes, implementing regular maintenance and using high-quality materials, manufacturers can quickly fix these issues and minimize their impact. Through ongoing innovation and strategic planning, businesses can ensure their systems run smoothly and reliably, ultimately enhancing productivity and reinforcing brand trust.

Interested in learning more about advanced solutions to stabilize your systems and extend equipment lifespan? Contact us today to discover tailored approaches that meet your specific operational needs.https://www.powsmart.com/product/electric-toothbrush/

Is Your Water Flosser Saline Solution Compatible for Effective Calcified Deposit Remover?

.jpg)

Ultra-Fine Bristle Electric Toothbrush Wholesale – Sensitive Care OEM Supply

Five benefits of using a Wave electric toothbrush

.jpg)

Dental Clinic Toothbrush Bulk Supply | Reliable Oral Care Distributor

.jpg)

FDA Certified Electric Toothbrush Supplier | Trusted B2B Oral Care Manufacturer

.jpg)

Travel Electric Toothbrush with Case – Compact & Rechargeable B2B Supply

.jpg)

Gel Crystallization with Gingival Discoloration – Alarming?

Is a Business owner toothbrush worth a Surat premium gift investment?

.jpg)

USB rechargeable sonic toothbrush supplier

How Does a Smart Timer Chip Integrate with Pressure Sensor Technology for Safer Brushing?

.jpg)

Does Your Toothbrush Survive Adventures?

.jpg)

Powsmart Electric toothbrush Factory Springdale Arkansas

.jpg)

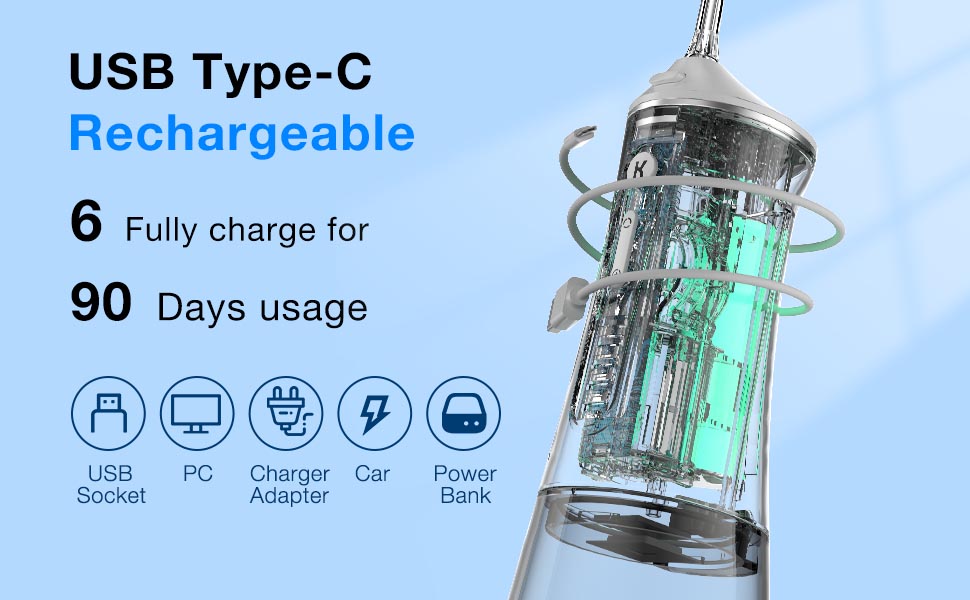

Electric Toothbrush Battery Life Engineering for OEM and ODM Manufacturing

How Does Your Whitening Gel Formulation Cater to a Sensitive Teeth Formula Requirement?

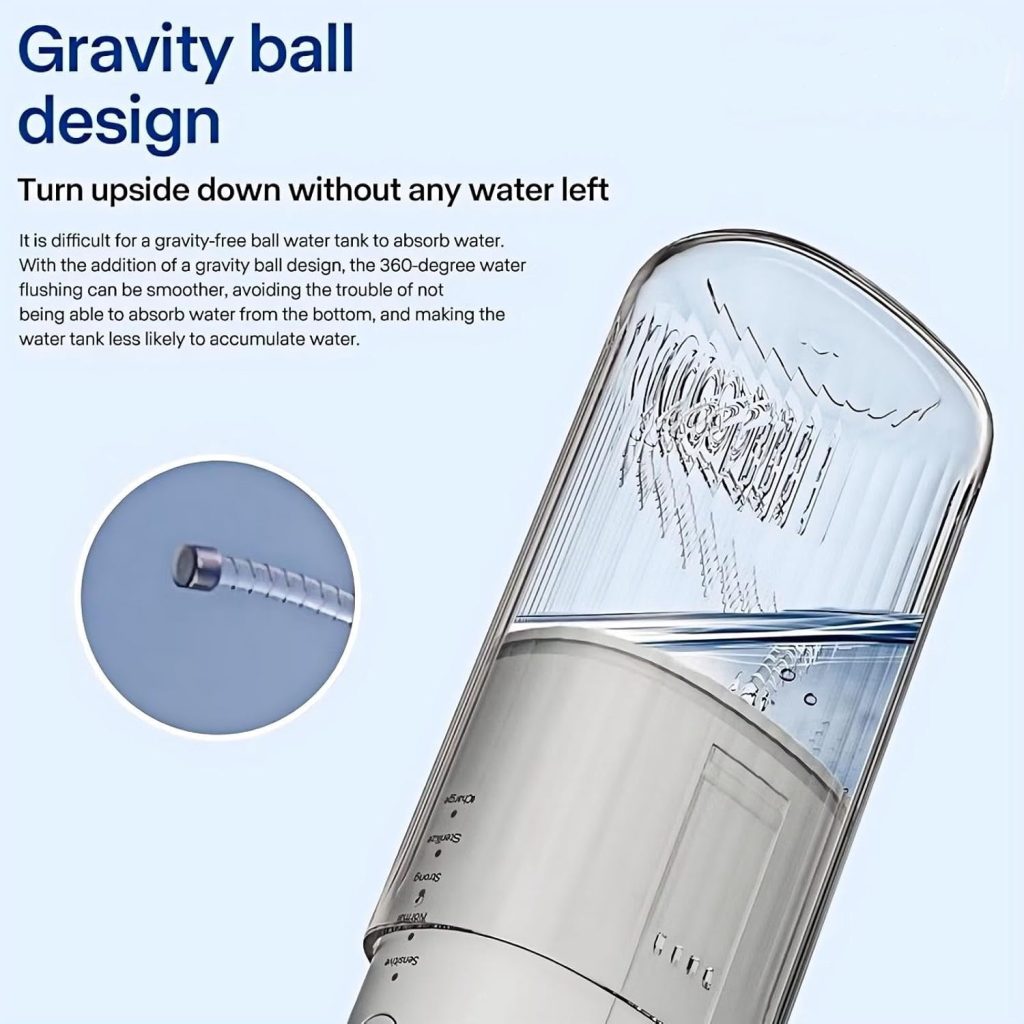

Does Optimal Flow Channel Design Reduce the Load on the Battery Management System?

Should Nozzle Material Always Be Medical-grade Material for Safety?