When users report inconsistent operation modes or sudden performance irregularities, two commonly overlooked root causes emerge: mode glitches and calibration drift. These two phenomena, though distinct in origin, often interact and compound each other, creating a confusing set of symptoms that frustrate users and burden support teams. Understanding the relationship between the two is key to ensuring product reliability in precision-driven devices.

Mode glitches refer to spontaneous or unintended switching, freezing, or misbehavior of a device’s operational modes. In products like water flossers, skincare devices, or precision cleaning equipment, these might include:

These glitches often stem from firmware instability, interference from internal sensors, or signal misprocessing, especially when real-time controls are involved.

Calibration drift happens when internal sensors or controllers gradually lose accuracy due to aging components, environmental exposure, or material fatigue. For example:

When calibration drift occurs, it skews the internal feedback loop, causing misalignment between expected vs. actual behavior—directly triggering mode inconsistencies.

The connection between the two is systemic. Calibration drift alters the baseline assumptions of the control logic. As a result:

Thus, mode glitches are not always bugs—sometimes they’re symptoms of degraded sensor trustworthiness.

In commercial or clinical use environments, mode glitching and calibration drift can be particularly disruptive:

These failures reduce customer confidence, increase training/support costs, and may even pose compliance issues in regulated markets.

To avoid this dual failure mode, B2B manufacturers should consider:

These steps significantly reduce long-term degradation, especially in high-use products.

Ignoring calibration drift today often results in escalated mode glitch complaints tomorrow. On the flip side, proactive drift management can deliver:

Addressing these interconnected issues is not just a technical necessity—it’s a competitive differentiator.

While mode glitches may appear random or user-induced, they frequently stem from deep calibration drift issues. Understanding this relationship empowers manufacturers to build smarter, more resilient systems that deliver stable performance across a product’s lifetime.

Looking to optimize your firmware, calibration protocols, or sensor systems? Reach out to our engineering team to explore tailored B2B solutions or advanced OEM collaboration opportunities. Contact us

Application of Water Transfer Printing and Thermal Transfer Printing on Electric Toothbrush Shell: 3D Texture and Wear Resistance Test

Is replacement head cost an important factor when choosing an electric toothbrush?

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8 for Humid Climates

Different types of water flosser nozzles and how to choose the right nozzle?

How To Prevent Mold in a Water Flosser?

How to Keep Teeth Clean with Braces?

.jpg)

Electric Toothbrush Troubleshooting Flowchart: A Practical OEM Guide for Brands

Mucosal Irritation with Chemical Residues – Toxic?

Travel Electric Toothbrush | Portable Oral Care

Can an electric toothbrush Houston truly elevate your Houston dental care routine?

FDA-Approved Antibacterial Bristles of Electric Toothbrush: A Safety Guide for Oral Care

Bulk Smart Toothbrush Washington | Dental Giveaway & Corporate Programs

Is Your Electric Toothbrush Losing Power Too Fast?

Battery Depletion with Pressure Fluctuation – Linked?

.jpg)

Senior-Friendly Oral Care: Design & Sourcing Considerations for Aging Adults

The process of brand owners customizing OEM whitening teeth Kit

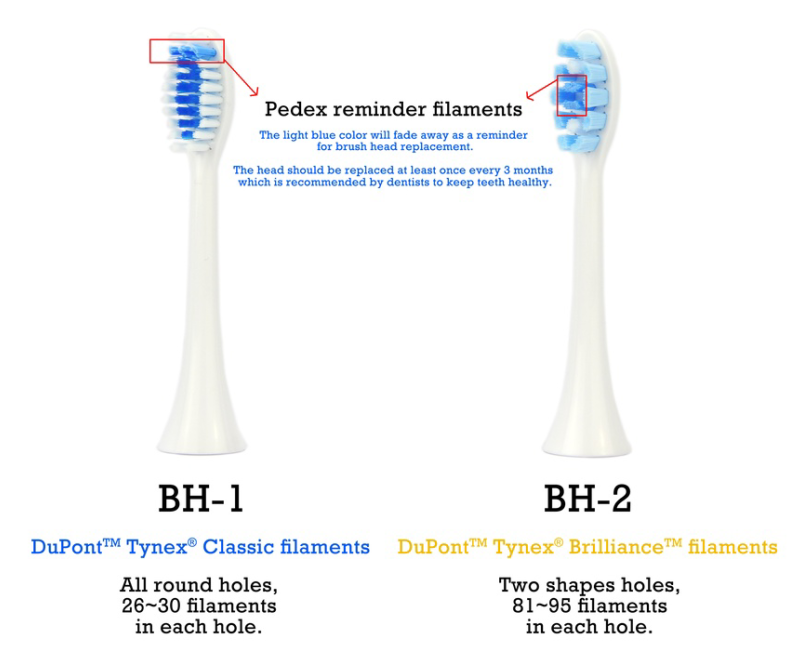

electric toothbrush heads Regular Clean

electric toothbrush heads Deep Clean

electric toothbrush heads Charcoal Infuse-Round

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Electric toothbrush heads Charcoal Infused-Diamond

Customization Teeth Whitening Gel

Private Label Whitening Gel

electric toothbrush heads Ultra Soft

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638