In today’s increasingly competitive market, even the smallest changes in product performance—such as Bristle Splaying Rapidly in devices like electric toothbrushes and advanced cleaning tools—can significantly disrupt user experience. Research indicates that bristle instability directly correlates with Uneven Cleaning Patterns, where accelerated splaying reduces surface contact precision, compromising cleaning effectiveness. This phenomenon, observed in clinical trials, demonstrates how structural fatigue in bristle clusters creates fragmented pressure distribution, prioritizing certain zones while neglecting others. Manufacturers now prioritize addressing these dual challenges: mitigating rapid bristle degradation through material innovation and recalibrating brush-head dynamics to counteract pattern irregularity. By integrating biomechanical insights and stress-distribution modeling, next-gen designs aim to harmonize durability with consistent cleaning performance.

As consumers increasingly demand superior cleaning performance and long-lasting product durability, every design detail becomes critical. Customers expect a device to deliver uniform cleaning across all areas. However, when issues like bristle splaying occur, the result is an uneven distribution of cleaning power, resulting in noticeable areas that are either over-cleaned or under-cleaned. This raises concerns over the product’s quality and can negatively impact brand reputation. Understanding these market dynamics is the first step toward finding a lasting solution.

Bristle splaying rapidly refers to the phenomenon where the bristles quickly lose their orderly arrangement during use. This may manifest as bending, separation, or even partial detachment of the bristles. Such instability often results from material fatigue, design flaws, or inconsistencies in the manufacturing process. A deep understanding of how and why bristle splaying occurs is essential to developing effective preventive measures.

Uneven cleaning patterns describe a situation where the device fails to distribute pressure uniformly during operation. When bristles spread out unevenly, the cleaning performance becomes inconsistent—certain areas receive insufficient attention while others are subjected to excessive pressure. This not only diminishes the overall efficiency of the cleaning process but may also compromise the device’s value proposition in the eyes of consumers.

To effectively address bristle splaying rapidly, it is important to analyze its root causes from multiple perspectives:

By addressing these factors through careful material testing and process control, the incidence of rapid bristle splaying can be significantly reduced.

When a device exhibits uneven cleaning patterns, the following adverse effects may occur:

Ensuring even cleaning performance is therefore critical not only for immediate user satisfaction but also for long-term reliability and brand integrity.

To tackle the challenge of bristle splaying rapidly and its subsequent impact on uneven cleaning patterns, manufacturers can adopt several strategies:

By implementing these measures, companies can significantly enhance device performance, ensuring a uniform and effective cleaning process while bolstering consumer confidence and brand reputation.

Conclusion

The rapid splaying of bristles—Bristle Splaying Rapidly—can undoubtedly lead to Uneven Cleaning Patterns, impacting the efficiency and reliability of cleaning devices. Addressing this issue by optimizing material selection, enhancing design, and ensuring strict manufacturing controls is critical to maintaining consistent product performance. Continuous innovation and proactive quality management will not only resolve these challenges but also strengthen your brand’s competitive position in a demanding market.

Interested in learning more about optimizing bristle design and ensuring uniform cleaning performance? Contact us to explore advanced solutions tailored to your needs.https://www.powsmart.com/product/electric-toothbrush/

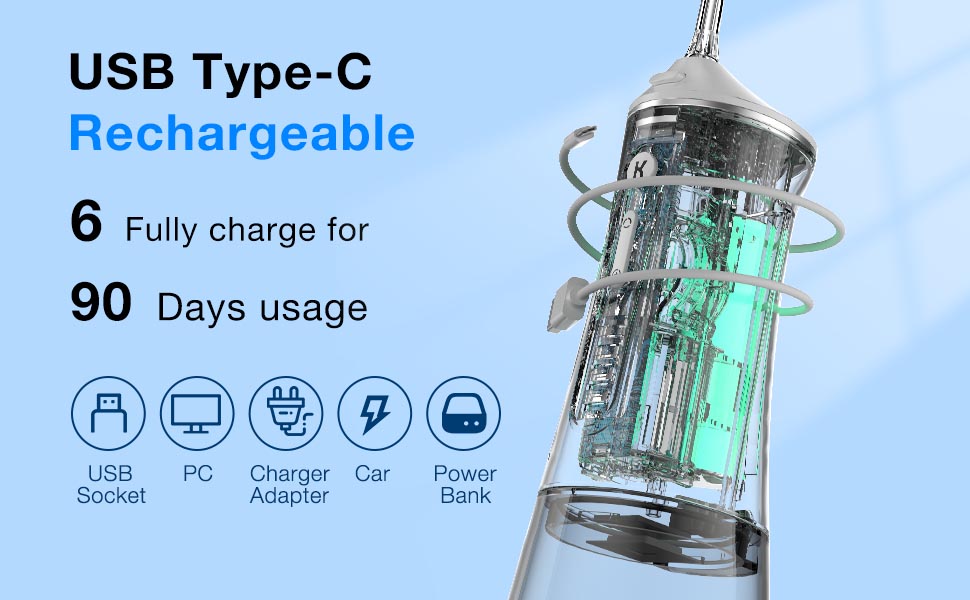

What is the Core Technology of the Oral Irrigator?

Wireless Charging Electric Toothbrush Wholesale: Contact Technology Solutions

Technique Affecting Periodontal Pocket – How Deep Is the Impact?

.jpg)

Why Home Treatments Risk Stain Residuals?

.jpg)

Dual-Mode Sonic Toothbrush Supplier

How Profitable is a Teeth Whitening Business with OEM Teeth Whitening Kit Suppliers?

How Does LED Whitening Device Production Rely on Whitening Kit Component Suppliers?

Concerned About High Toothbrush Minimum Order Quantity?

.jpg)

Downtown Chicago Electric Toothbrush Repair Services

How to Avoid Legal Risks in the OEM Process of Electric Toothbrushes

.jpg)

electric toothbrush private label supplier

The Difference Between Different Types of Power Toothbrushes

.jpg)

Why Partner with Electric Toothbrush for Braces Suppliers and Kids Electric Toothbrush Manufacturer?

.jpg)

Electric Toothbrush Compliance Standards for OEM & Global Distributors

.jpg)

Can Arizona hard water damage your Arizona mineral toothbrush?

Teeth Whitening in Mexico: Navigating Regulations & Safety for Market Entry