In the competitive oral care market, product differentiation often starts with something simple yet crucial — the toothbrush handle. While bristle quality and motor performance draw attention, handle design plays a vital role in user comfort, safety, and brand perception.

For OEM brands looking to compete with industry leaders, understanding the Oral-B style handle is key to balancing ergonomic design with manufacturing efficiency.

The Oral-B style handle has become an industry benchmark, not only for its recognizable aesthetics but also for its advanced ergonomics. This handle style often integrates dual-material molding, combining hard plastic cores for structure with soft elastomer surfaces for enhanced grip and comfort.

This dual-material approach allows for better control during brushing and improved tactile feedback — essential features that today’s consumers expect in premium toothbrushes and power brush handles.

Dual-material molding (also known as two-shot or overmolding) is a process where two materials are combined into one cohesive handle. For OEM manufacturers, this technique enhances both functionality and visual appeal:

Improved Grip Technology: The softer material provides non-slip properties even in wet conditions.

Enhanced Aesthetics: Contrasting colors and finishes create a more premium, professional look.

Durability: The fusion between materials reduces the likelihood of peeling or wear.

While the technology demands higher tooling investment initially, it delivers long-term value through better user satisfaction and brand differentiation.

Adopting Oral-B style handle designs involves evaluating trade-offs between upfront mold costs and product positioning benefits.

Tooling & Setup: Dual-material molds are more complex and expensive to produce.

Production Efficiency: Once established, cycle times remain competitive and scalable.

Brand Premium: The end product commands higher retail margins and reinforces brand credibility.

For mid- to high-tier brands, this investment often yields substantial returns through consumer loyalty and reduced aftersales issues related to poor ergonomics or material fatigue.

Not all factories are equipped to handle dual-material molding with consistent precision. When sourcing a partner, OEM brands should assess:

Injection Molding Capabilities: Availability of multi-shot or overmolding machines.

Experience with Oral-B Style Designs: Proven track record in producing similar ergonomic handles.

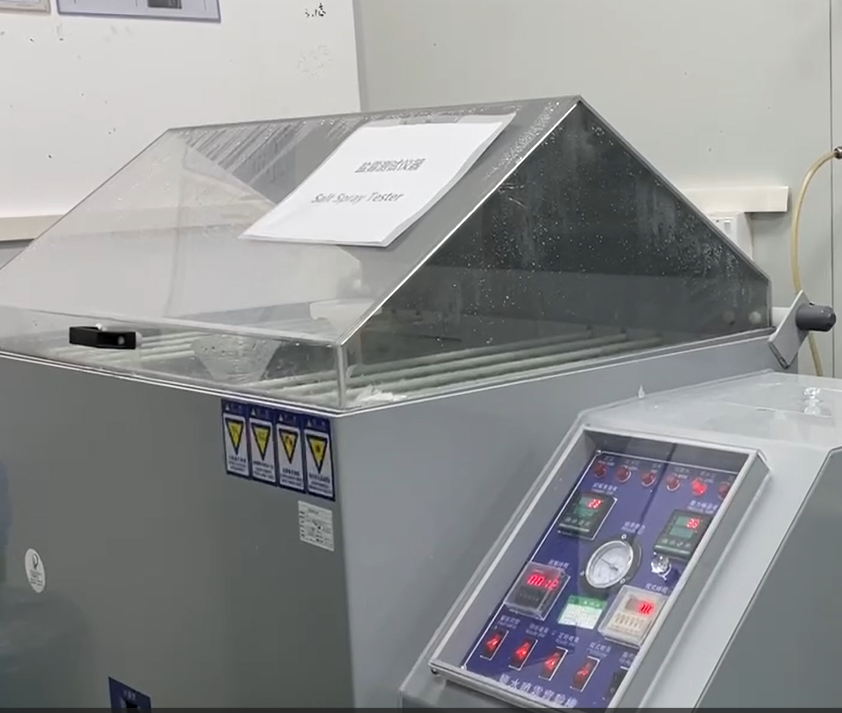

Quality Control Systems: Testing for adhesion strength, grip durability, and finish consistency.

R&D Support: Ability to co-develop new handle geometries and surface textures for better grip technology performance.

A strong OEM partner not only provides manufacturing services but also supports innovation, helping your brand stay ahead of consumer trends.

Adopting Oral-B style handle technology is not just about copying a design. It’s about leveraging proven ergonomics and grip technology to enhance user experience. By understanding the OEM cost-benefit equation and partnering with capable dual-material molding specialists, brands can create toothbrushes that feel premium, perform reliably, and stand out on retail shelves.

For oral care brands seeking to expand or optimize their product lineup, now is the time to turn handle technology into a competitive advantage.

Smart Electric Toothbrush OEM: Advanced Features for Modern Brands

.jpg)

Perfect Pressure Every Time: Designing User-Friendly Water Flosser Settings for Your OEM Brand

What Are the Benefits of Our Patented Structural Design for Electric Toothbrushes?

.jpg)

Electric Toothbrush for Professional Dental Kits – Clinical-Grade Oral-Care Solutions

Electric Toothbrush for Students: Budget-Friendly OEM Options

Anti-Swallow Design in Kids’ Electric Toothbrushes – Custom Manufacturing

Clean & Maintenance Tips for Your Sonic Electric Toothbrush

Which of the Two Marketing Strategies for Electric Toothbrushes – “Feature Overload” or “Simplicity and Practicality” – Would You Choose?

.jpg)

Weak Vibration Plus Sensor Failure – Double Malfunction?

How Does Pulse Water Technology Incorporate a Gum Protection Feature?

.jpg)

Research on Consumers’ Preferences for the Functions and Prices of Electric Toothbrushes – From the Perspective of Suppliers

.jpg)

Do Water Flosser Battery leakage and Overheat Dangerously?

Reducing Electric Toothbrush Auto power-On Failure Rates: Manufacturer’s 3-Fold Guarantee from Design to Assembly

.jpg)

Can Innovative Water Flosser Design Incorporate an Ergonomic Flosser Handle for User Comfort?

Electric Toothbrush Charging Dock OEM: Stylish and Functional Accessories

.jpg)

Is Battery Swelling Causing Pressure Loss?