As water flossers become increasingly popular for daily oral hygiene, one question frequently arises from users and distributors alike:

“Why can’t the nozzle of the water flosser be disassembled and replaced like a toothbrush head?” understanding the technical and design reasons behind this decision is essential. In this blog, we dive into the factors that influence nozzle design and explore how water flosser manufacturers prioritize safety, hygiene, and product durability in their engineering choices.

Unlike toothbrush heads, the nozzle of the water flosser is not just an attachment—it is a pressure-sensitive component. Many nozzles are structurally integrated with the body or water channel to ensure:

Allowing users to disassembled and replace the water flosser nozzle without proper sealing mechanisms could result in water leakage, reduced device efficiency, or even user injury.

From a medical and hygiene standpoint, a fixed or semi-fixed nozzle design allows manufacturers to:

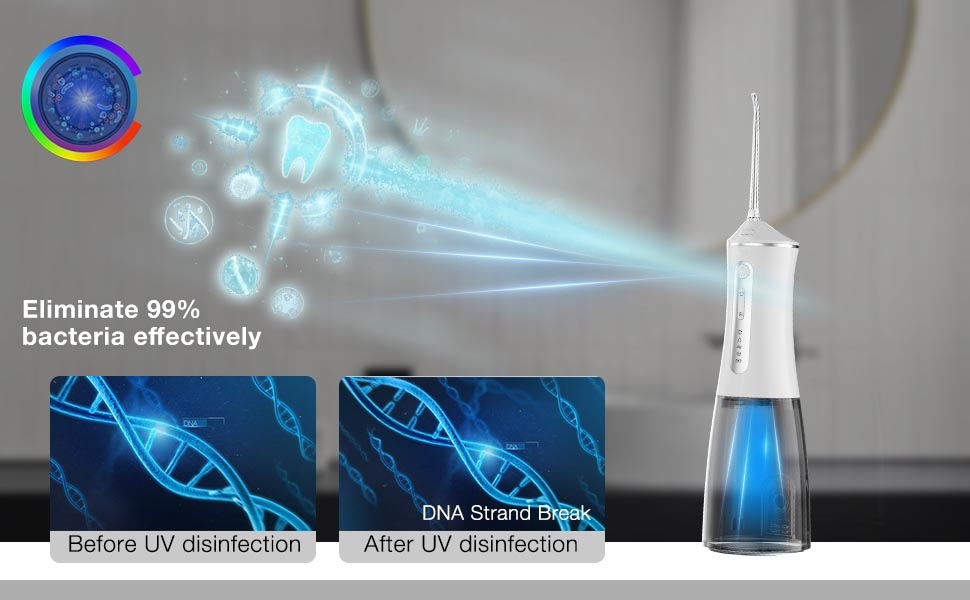

Leading water flosser manufacturers conduct extensive testing to ensure the internal structure remains sterile and safe throughout regular use. A detachable nozzle may introduce hygiene risks that are difficult to control in non-clinical settings.

A fixed nozzle design offers superior durability over time. Repeated insertion and removal of a detachable nozzle can cause:

For this reason, many manufacturers prefer to design the nozzle of the water flosser as a semi-permanent part, engineered to last through the device’s full usage cycle.

That said, some professional water flosser manufacturers do offer OEM/ODM options where replaceable nozzles are available—especially for products intended for multi-user or clinical use.

In such cases, manufacturers implement:

This allows brands to strike a balance between convenience and safety based on their target audience.

The decision not to allow users to freely disassemble and replace the water flosser nozzle is not a limitation—it’s a deliberate design choice:

Maximizing pressure performance

Ensuring hygienic operation

Extending product durability

At the same time, advanced water flosser manufacturers provide customized solutions for brands needing replaceable nozzles, ensuring both flexibility and safety.

? Looking to develop a custom water flosser with replaceable nozzles? Contact our engineering team for tailored OEM support.https://www.powsmart.com/contact-us/

The Market Potential of Teeth Whitening: The Consumer Psychology Behind Annual Growth of Home Teeth Whitening Devices

How Does Your LED Whitening Lamp Activate Our Whitening Gel Formulation?

.jpg)

LA Affordable Toothbrush – Budget-Friendly Oral Care

Teeth Whitening in Mexico: Navigating Regulations & Safety for Market Entry

.jpg)

Professional Teeth Whitening Supplier China for Global Distributors

.jpg)

Can a Florida electric toothbrush soothe Florida sensitive gums?

.jpg)

Dental Hygienist Promo Products Supplier | Oral Care Marketing Tools

.jpg)

Can Chemical Burns from Whitening Kits Cause Crown Discoloration?

Can the Water Flosser Work if It’s Moldy and Smelly?

Competitive Water Flosser Features That Drive Sales

.jpg)

Custom Oral Care Products Manufacturer for Private Label Brands

How Does Desktop Irrigator Design Incorporate an Anti-bacterial Hose for Hygiene?

The Science Behind Sonic Toothbrush Motors

Can a Dual Care Brush Be Both a Teeth Whitening Brush and Gum Massager?

.jpg)

High Pressure Oral Irrigator OEM – Bulk High-Power Water Flosser Manufacturing

.jpg)

Low MOQ Sonic Toothbrush Supplier for Emerging Oral Care Brands