In the competitive oral care market, product performance and differentiation are closely tied to core components. Servo Motor Customization plays a vital role in elevating OEM/ODM Manufacturing capabilities for precision toothbrushes, enabling brands to achieve superior control, consistency, and adaptability across diverse product lines.

Customized servo motors allow manufacturers to fine-tune speed, torque, and vibration frequency. This precision is essential in OEM/ODM Manufacturing, ensuring every toothbrush delivers stable and repeatable brushing performance that meets brand specifications.

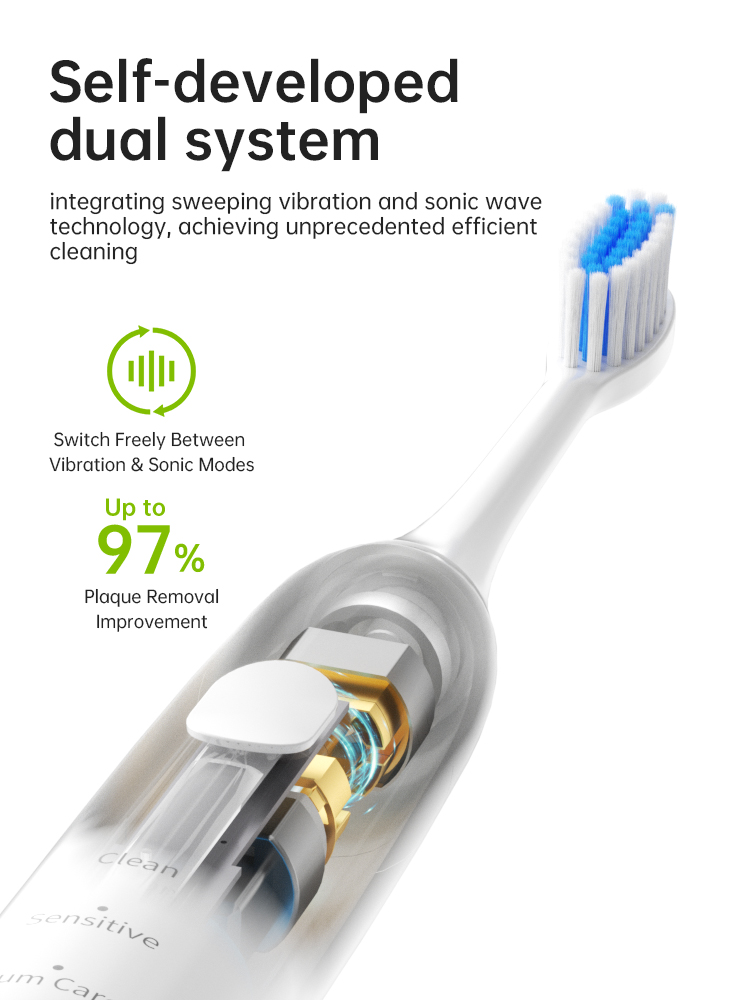

With Servo Motor Customization, a single platform can support multiple brushing modes such as sensitive, whitening, or deep clean. This flexibility enhances OEM/ODM Manufacturing efficiency by enabling faster development of differentiated models without redesigning the entire system.

Tailored servo motors can be optimized for power consumption based on brushing intensity and duration. This directly benefits OEM/ODM Manufacturing by extending battery life, reducing energy loss, and supporting compact or travel-friendly toothbrush designs.

Noise level and vibration comfort are critical user experience factors. Servo Motor Customization allows precise balancing and damping adjustments, helping OEM/ODM Manufacturing partners deliver quieter, smoother precision toothbrushes that meet premium market expectations.

Customized servo motors can designed to integrate smoothly with sensors, control chips, and firmware. This compatibility strengthens OEM/ODM Manufacturing capabilities, especially for smart toothbrushes requiring pressure sensing, timers, or app connectivity.

By developing servo motors tailored to specific product requirements, manufacturers can reduce engineering iterations and validation cycles. This streamlined approach makes OEM/ODM Manufacturing more agile, allowing brands to launch precision toothbrushes faster and with greater confidence.

Servo Motor Customization is a strategic enabler for advanced OEM/ODM Manufacturing in the precision toothbrush sector. By delivering superior control, flexibility, and integration potential, customized servo solutions help brands stand out with reliable performance, enhanced user experience, and scalable product innovation. Contact us

-1.jpg)

.jpg)

Why Offer B2B Water Flosser Customization for Eco Friendly Water Flosser Demand?

The Importance of Water Resistance for Teeth Whitening Devices and Anti-Saliva Corrosion Structure

.jpg)

Holi Family Gift Pack Electric Toothbrush Ahmedabad

How Does Quad-brush Synchronization Technology Enhance Laminar Flow Nozzle Performance in Water Flossers?

.jpg)

Why Are OEM Toothbrush Heads Essential for a Successful Toothbrush Subscription Service Model?

.jpg)

Tank Scaling Causing Part Incompatibility?

All-in-One Family Toothbrush Solution

Are Electric Toothbrushes a Good Investment?

1200 vs 1800 water flosser pulse/Minute: Which Water Flosser Pressure Setting Works Best for Plaque Removal Without Gum Irritation?

.jpg)

Why Does Poor Cleaning Leave Fiber Residue?

New Year Resolution for Better Oral Health: OEM Product Planning

.jpg)

Wholesale Waterproof Electric Toothbrush Washington Outdoor | Adventure Ready

3 Essential Capabilities of a High-Quality Oral Irrigator Manufacturer: Why Global Brands Choose Us

What Safety Precautions Should Be Taken When Installing the Electric Toothbrush Head?

.jpg)

Procuring Electric Toothbrush for Hotels Supply?

How Much Do You Know About the Manufacturing Industry of Home Teeth Whitening Products?