For modern oral care devices, durability is no longer optional—it is a baseline expectation. A reliable PCB Assembly Service must integrate seamlessly with a Waterproof IPX7 Solution to ensure long-term performance in wet environments such as bathrooms and daily rinse cycles. Achieving this integration requires close coordination between electronics engineering and waterproof structural design.

Effective waterproofing starts at the PCB design stage. A professional PCB Assembly Service considers component placement, trace routing, and board shape to align with sealing structures required by a Waterproof IPX7 Solution.

Not all electronic components perform reliably under high-humidity or immersion conditions. Selecting moisture-resistant ICs, connectors, and passive components is essential to support a stable Waterproof IPX7 Solution.

Conformal coating, potting, or selective encapsulation are often applied during PCB Assembly Service processes. These protective layers work in tandem with mechanical seals to reinforce the overall Waterproof IPX7 Solution.

Precision soldering, controlled cleaning, and residue management help eliminate micro-gaps that could compromise waterproof integrity. Process discipline within the PCB Assembly Service directly affects the success of IPX7-level sealing.

A seamless integration requires joint validation. Functional electrical testing combined with immersion and pressure testing ensures the PCB Assembly Service output fully complies with Waterproof IPX7 Solution standards.

Oral care devices experience repeated exposure to water, vibration, and temperature changes. A well-integrated PCB Assembly and Waterproof IPX7 Solution reduces failure rates and extends product lifecycle in real-world use.

A durable oral care device depends on more than waterproof housing alone. When a PCB Assembly is designed to integrate seamlessly with a Waterproof IPX7 Solution, manufacturers gain higher reliability, fewer field failures, and stronger brand credibility. For OEM and ODM partners, this integration is a critical foundation for next-generation oral care products. Contact us

Reasons Why the Water Pressure of Your Water Flosser Decreases (And How to Fix It)

.jpg)

Pulp Inflammation After Periodontal Pocket Deepening – Emergency?

10 Eco-Friendly Oral Care Upgrades for Your OEM Product Line

.jpg)

Gel Crystallization with pH Imbalance – Toxic?

Electric toothbrushes: Eco-friendly and sustainable oral care

.jpg)

Enamel Wear from Overbrushing Habit – Reversible?

How Can Oral Care Product Brands Improve Customer Trust Through Content Marketing?

.jpg)

Is Tooth Sensitivity with Enamel Erosion Whitening’s Side Effect?

Is a TSA Friendly Toothbrush with Portable Toothbrush Case Truly Hassle-Free at Airports?

.jpg)

When Selecting Products, How Can You Make the Pricing of Electric Toothbrushes Best Suit Your Brand Image?

.jpg)

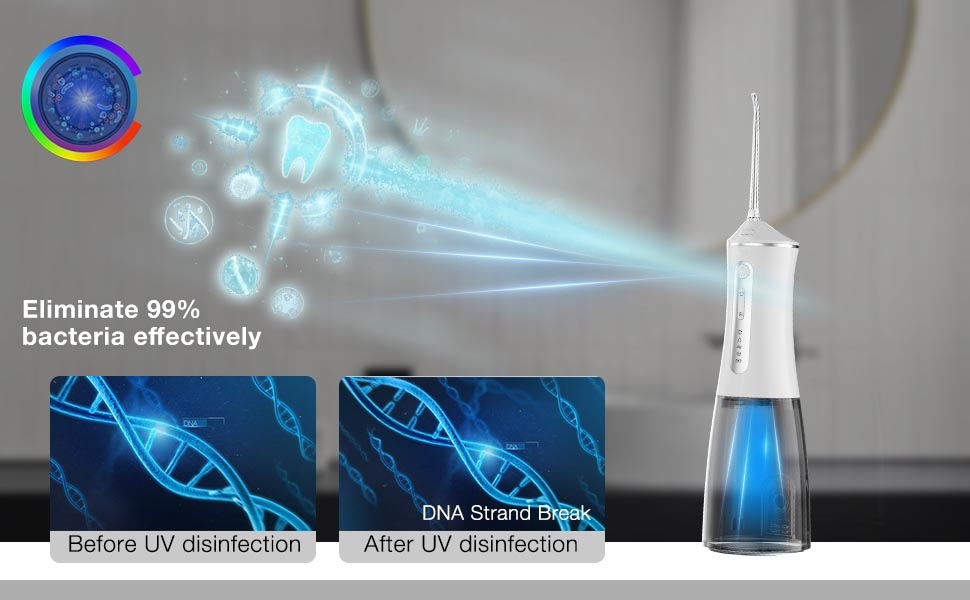

The Role of UV Light in Water Treatment for Modern Oral Care Products

Professional Teeth Whitening Business Starter Kit – High-Profit OEM Kit

.jpg)

Why Offer B2B Water Flosser Customization for Eco Friendly Water Flosser Demand?

.jpg)

Orthodontic Electric Toothbrush OEM: Specialized Care Solutions

.jpg)

ABS Nozzle Smart Molding & Cycle Optimization | Manufacturing Efficiency

.jpg)

LED Whitening Mouthpiece | Fast-Acting Light Therapy for Teeth OEM/ODM Solution