For oral care brands seeking long-term growth and product credibility, finding the right electric toothbrush factory is critical. In today’s competitive market, quality, consistency, and regulatory compliance are essential. This blog serves as a practical guide for brand owners to conduct a structured electric toothbrush factory evaluation, covering the key factors that ensure your product meets both market expectations and global toothbrush production standards.

Below are 5 must-read criteria to help you identify a reliable manufacturing partner.

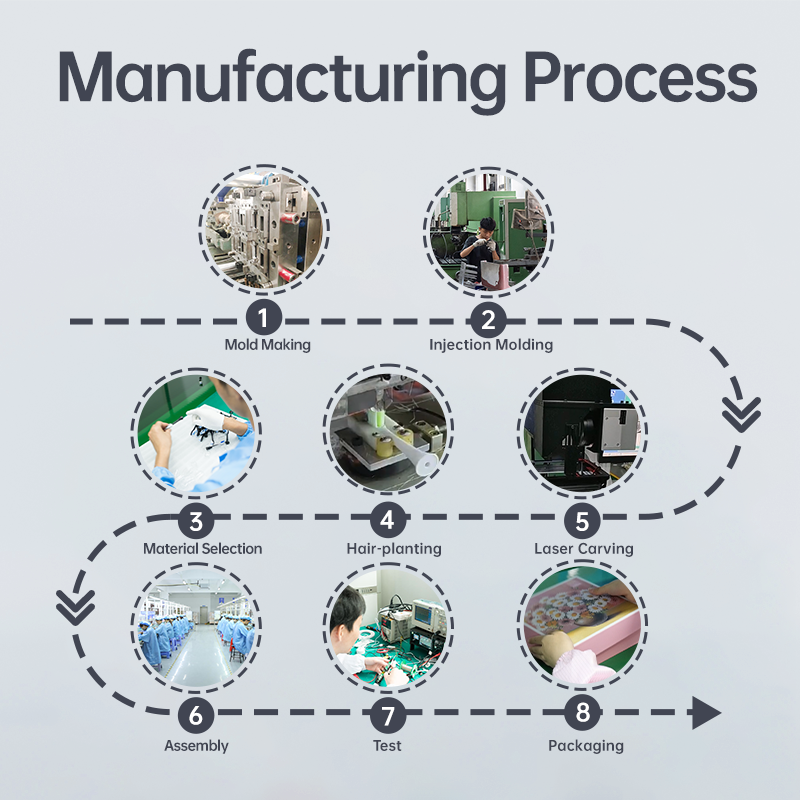

When evaluating a potential partner in oral care manufacturing, begin by examining their production scale and technical infrastructure. Key areas to consider include:

In-house mold development for brush heads and motor components

Automated production lines to ensure precision and consistency

Capacity to handle large OEM/ODM orders without quality compromise

A high-quality electric toothbrush factory will be able to demonstrate robust capabilities across all production stages, from injection molding to final assembly and packaging.

Global markets demand strict adherence to safety and quality regulations. A factory’s ability to comply with international toothbrush production standards is a non-negotiable factor. Look for compliance with:

ISO 13485 (for medical-grade manufacturing)

CE, FCC, FDA certifications depending on target markets

RoHS and REACH environmental safety standards

Request documentation to verify compliance during your OEM quality inspection process.

Consistent quality is vital for brand reputation. During your OEM quality inspection, ensure the factory follows rigorous QC protocols, such as:

Incoming Quality Control (IQC) of raw materials (e.g. bristles, motors, batteries)

In-Process Quality Control (IPQC) to catch issues early

Final Product Inspection (FQC) with functional testing, including battery life and water resistance

Ask the manufacturer for a full overview of their quality inspection procedures and defect rates.

Innovation drives differentiation. An excellent oral care manufacturing partner should offer strong R&D support, especially for brands targeting premium segments. Look for factories that provide:

Industrial design and 3D prototyping services

Firmware customization for smart toothbrush features

Packaging and branding integration

A partner with flexible development capabilities will help bring your brand vision to life faster and more cost-effectively.

Even the best product designs can fail if timelines and logistics fall apart. During your electric toothbrush factory evaluation, ask about:

Lead times for new product development and mass production

Inventory management and spare parts availability

Partnerships with key suppliers for core components

Supply chain transparency is essential for long-term cooperation.

Finding the right electric toothbrush factory requires more than just comparing prices. By focusing on these five key areas—manufacturing capabilities, standards compliance, quality systems, R&D strength, and supply chain reliability—brand owners can confidently choose a partner who aligns with their product and growth strategy.

Whether you’re launching a new oral care line or scaling an existing one, this structured electric toothbrush factory evaluation framework will help ensure your products meet consumer expectations and regulatory demands worldwide.

Looking for a trusted partner in oral care manufacturing? Contact us today to learn more about how our factory supports premium electric toothbrush OEM/ODM projects with full OEM quality inspection support and industry-leading production standards.https://www.powsmart.com/contact-us/

.jpg)

Fort Worth Electric Toothbrush Wholesale

.jpg)

San Diego Electric Toothbrush Wholesale

Four Core Factors Brand Owners Must Pay Attention to When Choosing Competitive Water Flossers

How Can Servo Motor Customization Optimize Precision in Brush Head Injection Molding for B2B Toothbrush OEMs?

About Powsmart

.jpg)

Phoenix Electric Toothbrush Wholesale

Is High-Frequency Vibration Harmful to Gums?

Does POWSMART Multi-Function Toothbrush Cause User Adaptation Struggles?

-2-scaled.png)

Does 3D Rotation Oscillation Brush Trigger Sensor Failure?

.jpg)

San Antonio Electric Toothbrush Wholesale

.jpg)

Austin Electric Toothbrush Wholesale | Retail Growth Guide

Can a Rechargeable Battery Solution power an LED Display Module efficiently in flossers?

How does Brush Head Mold Design influence the effective integration of Food-grade Bristle Material?

.jpg)

Gel Leakage Causing Chemical Burns – Still Ignoring It?

Why Pair Cosmetic Whitening Equipment with a Portable Charging Case?

Why Is the Anti-Swallow Structure in Powsmart Toddler Toothbrush Design Pediatrician-Recommended?