In today’s highly competitive personal care and home appliance market, maintaining product reliability is crucial for brand reputation and customer retention. However, Button failure and Bristle deformation have become major concerns, leading to an increasing number of product recalls. These issues not only result in financial losses but also damage consumer trust. In this article, we will explore the causes behind these failures and outline effective strategies to prevent them.

Product recalls are more than just a logistical headache; they can significantly impact a company’s brand image and financial health. When customers experience Button failure, where buttons become unresponsive, stuck, or loose, they quickly lose confidence in the product. Likewise, Bristle deformation in toothbrushes or cleaning devices can compromise functionality, leading to dissatisfaction and potential safety concerns. The rise in global consumer protection standards means that these issues must be addressed before they reach the market.

Button failure is often caused by poor material selection, inadequate structural design, or inconsistent manufacturing processes. Common issues include:

To prevent these problems, manufacturers must invest in high-durability materials, improve sealing mechanisms, and conduct rigorous life cycle testing.

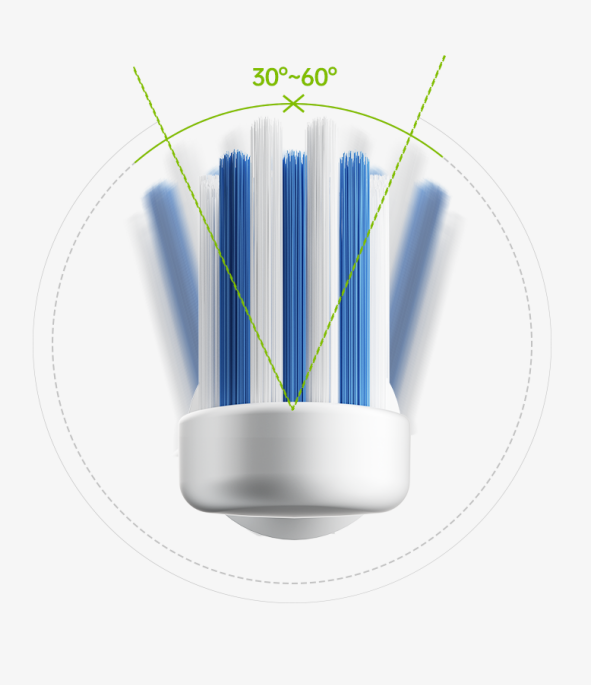

Bristle deformation occurs when bristles lose their shape, bend excessively, or break prematurely. This issue is particularly problematic for toothbrushes, cleaning brushes, and other hygiene-related products. The root causes include:

The consequences of Bristle deformation go beyond aesthetics—it can reduce cleaning effectiveness, cause discomfort, or even lead to hygiene concerns. To mitigate these risks, manufacturers should focus on using high-quality, heat-resistant bristle materials and refining production processes for enhanced durability.

Addressing Button failure and Bristle deformation requires a proactive approach in design and material selection. Manufacturers can consider:

By integrating these improvements, manufacturers can significantly extend product lifespan and reliability.

A robust quality control system is essential to minimize the risk of product failures before they reach consumers. Key measures include:

Companies that implement these quality control steps can drastically reduce failure rates and build a reputation for reliability.

Looking ahead, smart manufacturing and AI-driven quality monitoring will play a vital role in preventing Button failure and Bristle deformation. Innovations such as:

By leveraging these technologies, manufacturers can not only reduce recalls but also enhance consumer satisfaction and long-term brand loyalty.

Button failure and Bristle deformation are two common issues that can lead to costly recalls and damage brand credibility. By improving material selection, refining design structures, strengthening quality control, and adopting smart manufacturing practices, companies can ensure product reliability and customer trust. A proactive approach to these challenges will position manufacturers for sustained success in an increasingly demanding global market.https://www.powsmart.com/product/electric-toothbrush/

.jpg)

Smart Sonic Electric Toothbrushes: Family-Friendly, App-Connected for US & Canada Markets

.jpg)

custom color electric toothbrush | Color Customization Electric Toothbrush OEM

Rethinking LED Whitening in Your OEM Product Strategy

.jpg)

Are Erratic Brushing Mode confusion and Timers Failing Simultaneously?

.jpg)

Electric Toothbrush Quality Control in OEM & ODM Manufacturing

Custom Logo Electric Toothbrush Vendor: Private Label Solutions

Customizable Electric Toothbrushes: Meeting Diverse Consumer Needs

Top Chicago-Based Kids’ Electric Toothbrush Manufacturers for Safe & Fun Designs

.jpg)

Electric Toothbrush Customization Service for B2B Oral Care Brands

.jpg)

Hotel Amenity Electric Toothbrush Supplier | Premium Guest Oral Care

How Often Should You Use a Water Flosser?

-1-scaled.png)

How Red Light Therapy Boosts Gum Health in Advanced Oral Care Products

Compact Electric Toothbrush Design: Key Features for Travel & Minimalist OEMs

.jpg)

Powsmart Private Label Sonic Electric Toothbrushes: FDA-Certified OEM Solutions for Europe & US

Popular Electric Toothbrush Design Styles – OEM Trends for Brand Success

.jpg)

Electric Toothbrush Production Factory for OEM Manufacturing