Choosing a reliable teeth whitening products factory is crucial for ensuring high-quality products and successful business collaborations. Looking for Teeth whitening device OEM process or seeking a manufacturer for ODM/OEM cooperation? Evaluating potential suppliers based on key indicators can help you make the right choice. Here are five essential factors to consider:

A trustworthy teeth whitening products factory should comply with international quality and safety standards. Look for certifications such as ISO, FDA, CE, or GMP, which indicate that the factory follows stringent manufacturing protocols. Compliance with these regulations ensures that your products meet market entry requirements in different countries.

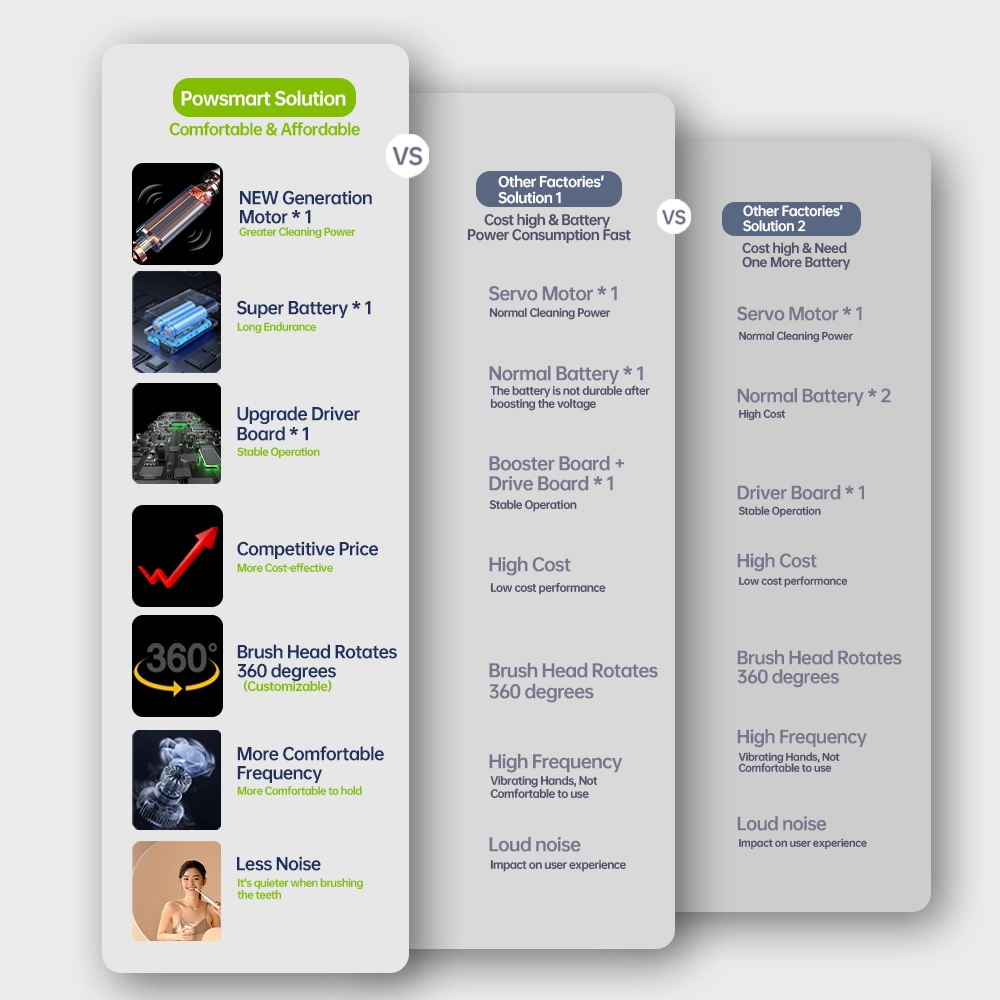

Experience plays a crucial role in determining the reliability of a factory. A manufacturer with a long-standing reputation in the industry will have refined production processes, extensive knowledge of whitening formulations, and advanced Teeth whitening device OEM process capabilities. Always check the factory’s track record and ask for case studies or client references.

It’s essential to ensure that the factory can customize products according to your branding and technical specifications. This includes custom formulations, packaging design, and logo printing. A good manufacturer should offer flexibility and provide professional R&D support. In order to develop innovative whitening products tailored to your market needs.

A reliable factory should have a strong production capacity to handle bulk orders without delays. Ask about the factory’s monthly production output, equipment, and workforce. Additionally, understanding the lead time for both sample production and mass production is essential to ensure a smooth supply chain and timely delivery.

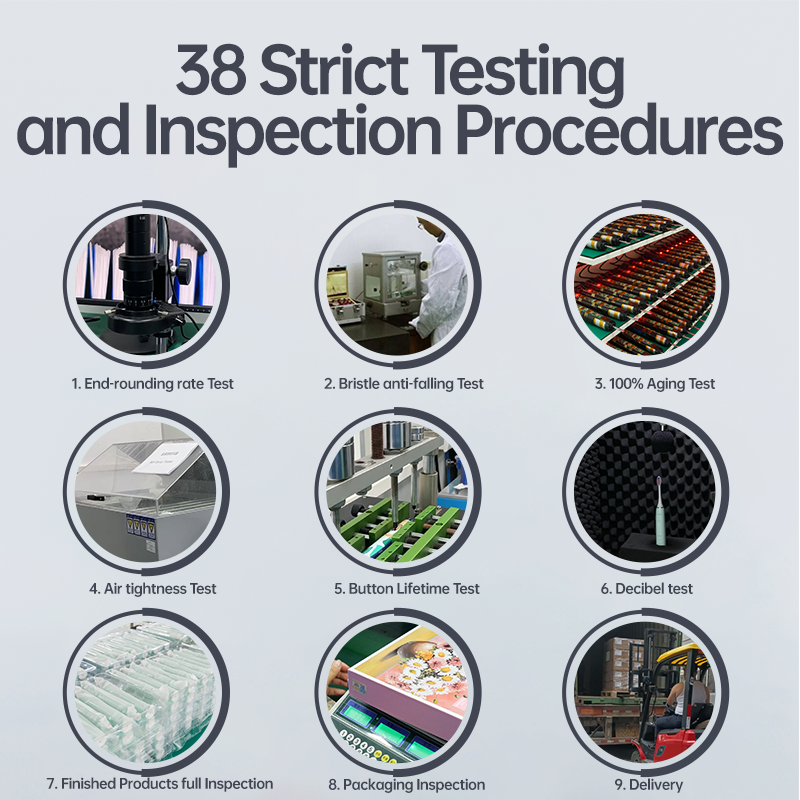

Quality control is a critical factor when selecting a teeth whitening products factory. Ensure that the manufacturer has a strict quality control system in place, including raw material inspection, in-process quality checks, and final product testing. Request information about testing procedures, product safety measures, and quality assurance reports to guarantee the effectiveness and safety of the whitening products.

Choosing a reliable teeth whitening products factory involves careful evaluation based on certifications, experience, customization capabilities, production capacity, and quality control. By partnering with a factory that excels in these areas, you can ensure a seamless Teeth whitening device OEM process and a successful ODM/OEM cooperation that meets market demands. Conduct thorough research, visit the factory if possible, and establish clear communication to build a strong and sustainable business relationship.

Environmentally Friendly Manufacturing and Sustainable Development of Electric Toothbrushes

.jpg)

Dental Hygienist Promo Products Supplier | Oral Care Marketing Tools

.jpg)

Can Short Tank Runtime Delay Oral Ulcer Care?

.jpg)

smart electric toothbrush OEM | Custom Smart Sonic Toothbrush Manufacturer

.jpg)

Children’s Day Gift Ideas Electric Toothbrush | Powsmart

Which Types of Water Flosser Does the ADA Recommended for Optimal Oral Health?

.jpg)

ADA Approved Electric Toothbrush Chicago

Analysis of the Core Components of the Electric Toothbrush: Technical Secrets from the Motor to the Brush Head

.jpg)

Incomplete Flushing after Flow Interruption?

.jpg)

Are Filter Degradation and Voltage Drops Linked?

.jpg)

Why Do Efficacy Comparisons Focus on Bleach Breakdown?

.jpg)

Hose Leakage Leading Mucosal Lesions – Double Damage?

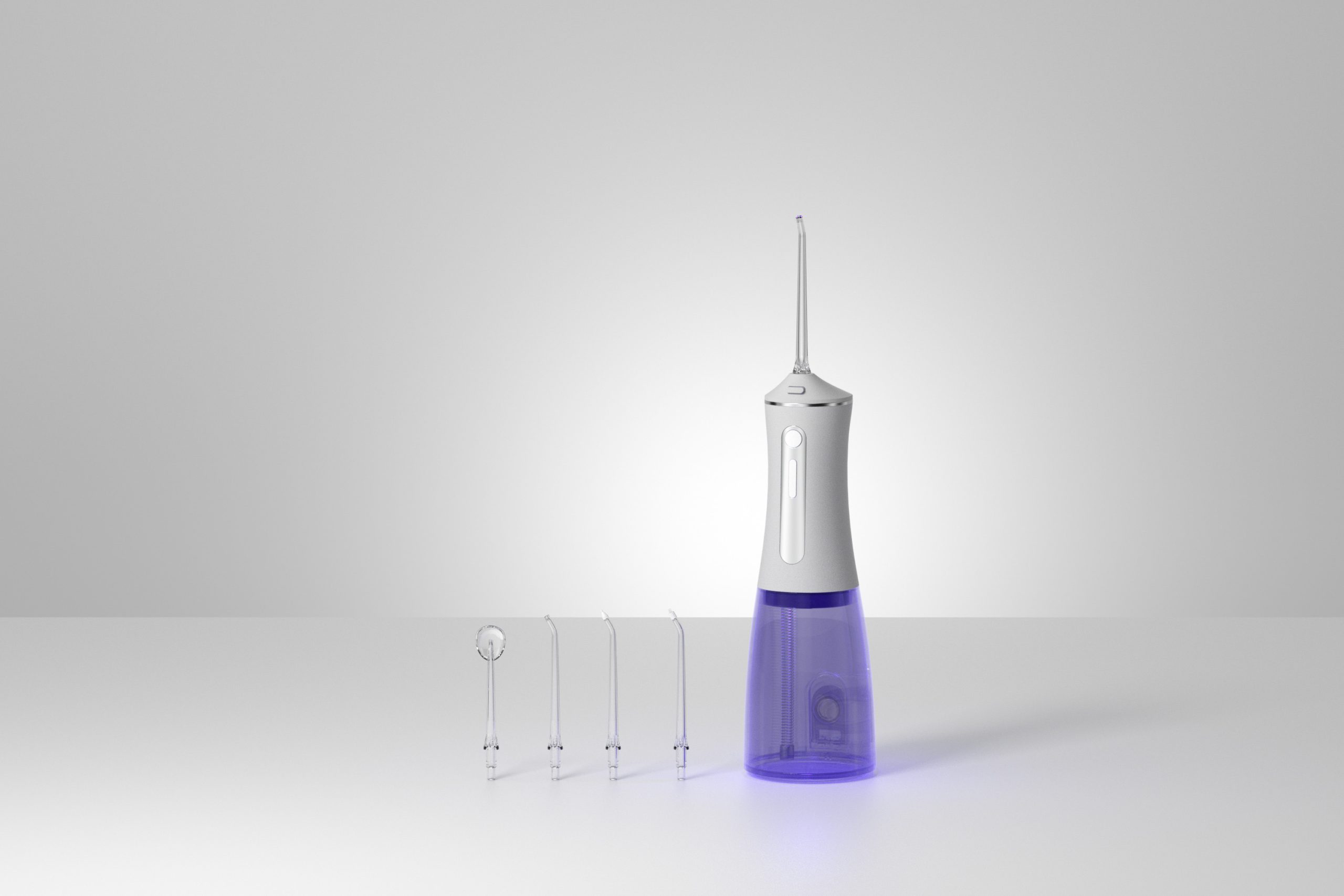

How to Pick the Right Water Flosser for Your Oral Health: Answers from an Oral Irrigator Manufacturer

What Safety Precautions Should Be Taken When Installing the Electric Toothbrush Head?

There Are Different Ways to Whiten Your Teeth, Which One Is Best for You?

.jpg)

Runtime Shortening with Battery Memory – Related?