In the competitive world of oral care devices, ensuring long-lasting performance and reliability is critical for gaining consumer trust. One of the key components of any water flosser is the motor, which drives the water pressure and determines the device’s effectiveness. To meet consumer expectations for durability and performance, it is essential to carry out thorough Water Flosser Motor Life Tests. Additionally, innovative design features such as mold venting play an important role in improving product longevity and functionality. In this blog, Powsmart technology co., ltd explores the relationship between motor life testing and mold vent design, and how these factors work together to create reliable, high-performance water flossers.

The motor in a water flosser is the heart of the device, responsible for generating the high-pressure water pulses that help remove plaque and debris between teeth. The motor’s longevity and efficiency directly impact the device’s overall performance and the user experience. Premature motor failure or performance issues compromise water flosser effectiveness, causing customer dissatisfaction. For manufacturers, testing the motor’s durability through Water Flosser Motor Life Tests ensures that the product will continue to function optimally throughout its expected lifespan.

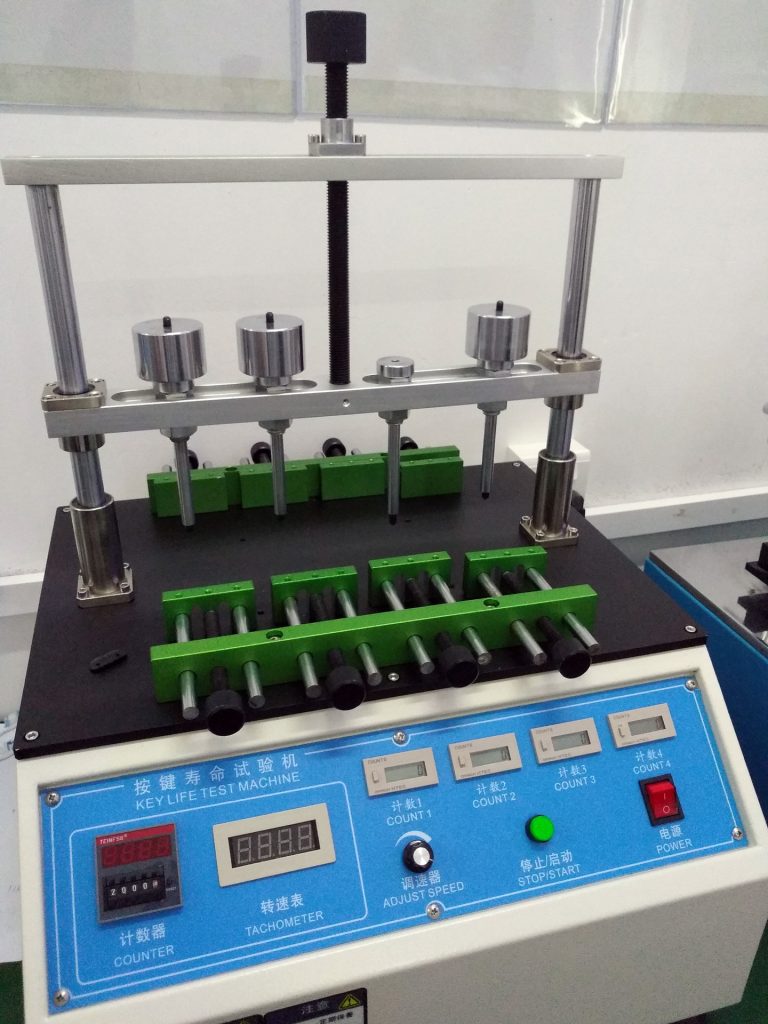

Water Flosser Motor Life Tests are designed to simulate the long-term use of a water flosser under various real-world conditions. These tests simulate long-term use by running the motor through continuous water pressure cycles. The objective is to assess the motor’s durability under pressure, temperature response, and post-use performance. This process helps manufacturers identify potential issues like overheating or motor components’ degradation before market release.

By conducting Water Flosser Motor Life Tests, manufacturers can ensure that each unit is built to withstand prolonged usage, providing a reliable and high-performing product for the consumer. These test results refine product design and quality control, ensuring durable, effective devices reach the market.

Mold venting is another key design element that affects the performance and longevity of the water flosser, particularly in relation to the motor. It refers to the incorporation of vents or air channels in the product’s casing or mold to facilitate proper airflow during manufacturing and operational use. These vents allow for better heat dissipation and airflow around the motor and internal components, preventing overheating during extended use.

Without adequate mold venting, the water flosser motor could overheat, causing damage to the motor or other critical components. By integrating effective mold venting strategies, manufacturers can improve the cooling system of the device, ensuring that the motor continues to perform efficiently over time, even during long usage sessions. This design feature contributes directly to the motor life by preventing excessive heat buildup, which can cause the motor to burn out prematurely.

While Water Flosser Motor Life Tests evaluate the motor’s performance under various conditions, mold vent design plays an integral role in ensuring the motor’s longevity during real-world usage. Areas needing better airflow or cooling are revealed by life tests and addressed through improved mold venting.

For example, if a water flosser motor experiences overheating in a specific area during testing, designers can use mold venting to create channels or vents that direct airflow to those areas, effectively improving heat dissipation. This type of iterative design and testing process ensures that the water flosser performs optimally, with a motor that lasts longer and operates at peak efficiency.

For consumers, the longevity of the water flosser motor is a key factor in determining satisfaction with the product. A motor that fails prematurely can lead to frustration and negatively impact the brand’s reputation. By investing in both Water Flosser Motor Life Tests and advanced mold venting design, manufacturers can significantly reduce the likelihood of motor failure and enhance the overall durability of the product.

A durable motor means fewer repairs and replacements, contributing to greater customer satisfaction and trust. A product rigorously tested for longevity and backed by superior engineering is recommended, strengthening brand loyalty.

As technology continues to evolve, the future of water flosser design will see even more advanced Water Flosser Motor Life Tests and mold venting solutions. For example, future testing may incorporate more precise simulations of real-world conditions, including varying water quality and external environmental factors. This will provide even more accurate data on how motors perform over time.

Additionally, mold venting designs will become increasingly sophisticated, utilizing new materials and innovative air-flow optimization techniques to ensure that water flosser motors remain cool and efficient. Staying ahead of design trends keeps products at the forefront, meeting growing consumer demands with reliable, long-lasting performance.

In conclusion, the combination of thorough Water Flosser Motor Life Tests and thoughtful mold vent design is essential for creating high-quality, durable water flossers. These elements ensure motor long-term efficiency and prevent overheating and damage. Advanced testing and design ensure products meet reliability, longevity, and performance expectations. As the oral care industry continues to evolve, these innovations will play a critical role in shaping the future of water flossers and ensuring that they deliver consistent, high-quality results for years to come.https://www.powsmart.com/about-powsmart/

.jpg)

dual-action electric toothbrush OEM

.jpg)

Where can you find a Texas Christmas gift that promotes healthy smiles?

How to Solve the Common Charging Problems When Using a Water Flosser?

Electric Toothbrush Head Customization Solution and Range

.jpg)

Wholesale Electric Toothbrush San Antonio – Affordable Oral Care for Businesses

Why Is a Smart Battery Management System Critical for a Portable Water Flosser?

.jpg)

Red Light Gum Therapy Whitening Device Supplier | LED Oral-Care OEM Manufacturer

.jpg)

Why Does Whitening Efficacy Decline Trigger Pulse Intensity Spikes?

.jpg)

How Brands Can Achieve Higher Margins with Premium Water Flossers

.jpg)

Boston Electric Toothbrush for Sensitive Gums

.jpg)

Indicator Failure Leading Periodontal Pocket Deepening – Undetected?

.jpg)

How to Build a Differentiated Oral Care Brand?

.jpg)

Waterproof Electric Toothbrush – OEM Manufacturing & Bulk Supply for Global Partners

.jpg)

Waterproof Travel Electric Toothbrush OEM | Portable Oral Care

Things you should know about LED teeth whitening devices

.jpg)

Is Your Toothbrush Head Manufacturer Aligned with the Sustainable Toothbrush Movement?