In today’s competitive oral care market, quality and durability are non-negotiable when it comes to devices like water flossers. With consumers demanding long-lasting performance and enhanced safety, Powsmart technology co., ltd focus on advanced surface treatments and stringent material certifications. In this blog, we delve into the importance of Water Flosser Anodizing and Steel Certification in ensuring that water flossers not only perform at their best but also withstand the rigors of daily use. Below, we break down these critical aspects into six detailed sections.

The modern consumer expects their water flosser to deliver consistent performance, even after prolonged use. Durability is a key factor that influences purchasing decisions. However, without robust surface treatments and certified materials, water flossers may quickly succumb to wear, corrosion, and mechanical failures. By emphasizing quality, manufacturers can ensure that their products remain reliable and safe over time.

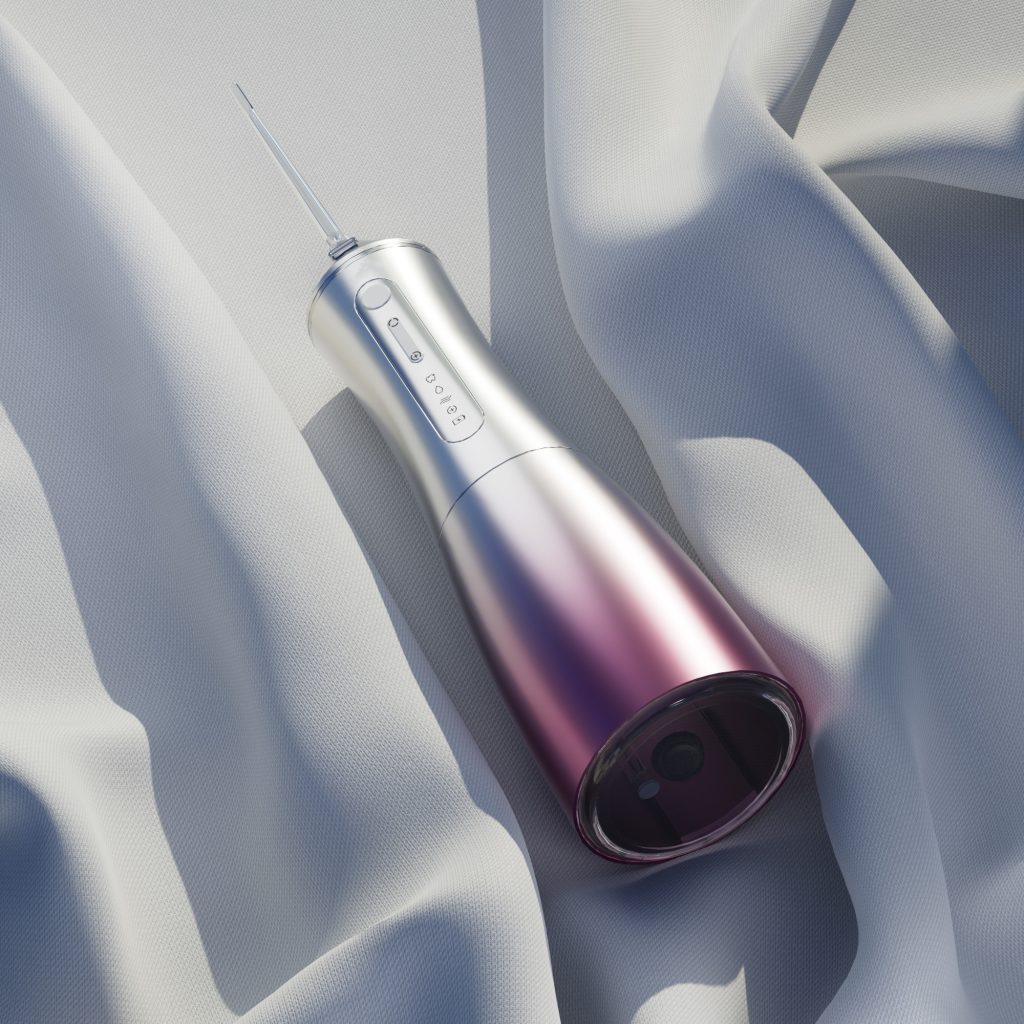

Water Flosser Anodizing is an advanced electrochemical process that transforms the surface of metal components into a protective, corrosion-resistant layer. This treatment not only strengthens the water flosser’s housing but also provides an attractive finish that resists scratches and everyday wear. Moreover, anodizing improves the adhesion of additional coatings, making it an essential step in delivering products that meet high performance and aesthetic standards.

Steel is a primary material used in many water flosser components, and ensuring its quality is paramount. Steel Certification verifies that the steel used meets strict industry standards for strength, durability, and safety. This certification process involves rigorous testing to ensure that the steel can withstand repeated impacts, high pressures, and exposure to corrosive environments. When a water flosser is built with certified steel, it offers greater reliability and longevity, instilling confidence in both end-users and distributors.

Combining Water Flosser Anodizing with Steel Certification creates a synergy that elevates product quality significantly. Anodizing enhances the external surface by providing a protective, non-reactive layer, while certified steel guarantees that the internal framework is robust and durable. Together, these processes ensure that every water flosser not only looks premium but also performs consistently under various conditions. Manufacturers who invest in both technologies can significantly reduce the risk of product failure, thereby improving overall reliability.

Products that boast advanced surface treatments and material certifications are more likely to stand out in a crowded market. When consumers see that a water flosser is built with Water Flosser Anodizing and uses Steel Certification-approved components, they immediately recognize the commitment to quality and longevity. This, in turn, leads to higher customer satisfaction, fewer returns, and enhanced brand reputation. In today’s competitive landscape, such assurances can be the deciding factor for distributors and retailers when choosing products to represent.

As technological advancements continue, the integration of even more sophisticated anodizing techniques and more rigorous steel certification standards will become commonplace. Future water flossers may feature multi-layered anodized coatings that further enhance durability, as well as smart monitoring systems to track the health of critical components. Manufacturers who keep pace with these innovations will not only meet but exceed consumer expectations, paving the way for a new era of high-performance, reliable oral care devices.

In summary, investing in Water Flosser Anodizing and ensuring Steel Certification are critical strategies for manufacturers looking to deliver high-quality, durable products. These processes guarantee that water flossers can endure daily use while maintaining optimal performance and safety. By integrating these advanced technologies, companies can boost consumer confidence, reduce maintenance issues, and secure a competitive edge in the ever-evolving oral care market.

Analyzing Oral-B Style Handle Technology: A Cost-Benefit Guide for OEM Brands

.jpg)

Electric Toothbrush for Plaque Removal – Professional Cleaning for Dental Businesses

.jpg)

Can Electric Toothbrush Private Label Models Leverage Electric Toothbrush Bulk Pricing?

Brooklyn Fast Local Delivery Electric Toothbrush Wholesale Suppliers

What Impact Will There Be If Only the Cost-Effectiveness of Price Is Considered When Sourcing Oral Care Products?

.jpg)

FDA Certified Electric Toothbrush Supplier | Trusted B2B Oral Care Manufacturer

.jpg)

Handle Grip Design Affecting Mucosal Irritation?

How Does This Quiet Electric Toothbrush Score in Noise Comparison Test?

How Does an LED Whitening Lamp Integrate into a Home Use Whitening System?

What is the Safest Teeth Whitening Method?

.jpg)

Soft Bristle Toothbrush Bulk Order Solutions for Importers

Why Pair Custom Teeth Whitening Tray Services with a Teeth Whitening Pen Manufacturer for Diverse Options?

Why can’t the electric toothbrush be charged?

.jpg)

Practical Mother’s Day Gifts Smart Toothbrush | Powsmart

.jpg)

Micro-Vibration Toothbrush OEM | Precision Sonic Cleaning for Global Distributors

Is waterproof design important for your bathroom essential toothbrush?