When sourcing from large-scale oral care manufacturers, the efficiency of water flosser accessory production plays a critical role in determining your overall oral irrigator bulk pricing. For distributors, dental brands, and private label buyers, partnering with a manufacturer that integrates accessory production — such as nozzles, chargers, and water tanks — directly into its main manufacturing process can lead to significant cost savings, faster turnaround, and better product consistency.

In this blog, we’ll break down how integrated accessory production helps optimize your supply chain, control pricing, and strengthen your brand’s market competitiveness.

Manufacturers that integrate water flosser accessory production with device assembly eliminate the need for multiple suppliers, reducing both communication and logistics complexity. Instead of outsourcing components like water tanks, tips, or power adapters, everything is produced under one roof.

This centralized process not only accelerates delivery schedules but also minimizes delays caused by supplier coordination. For bulk buyers, this integration ensures a smoother procurement cycle and ultimately lowers oral irrigator bulk pricing due to reduced overhead and administrative costs.

When all accessory parts — including nozzles, hoses, and charging cables — are produced in-house, manufacturers can better control raw material sourcing and processing costs. This efficiency directly impacts oral irrigator bulk pricing, giving distributors and private label brands more competitive rates.

With water flosser accessory production integrated into the main facility, waste materials can also be minimized, and economies of scale can be achieved across different models and product lines. This helps maintain consistent quality while offering flexibility in pricing for high-volume orders.

For oral care products, performance consistency is key. A high-quality oral irrigator depends on the precision and reliability of each accessory — from nozzle pressure control to waterproof seals.

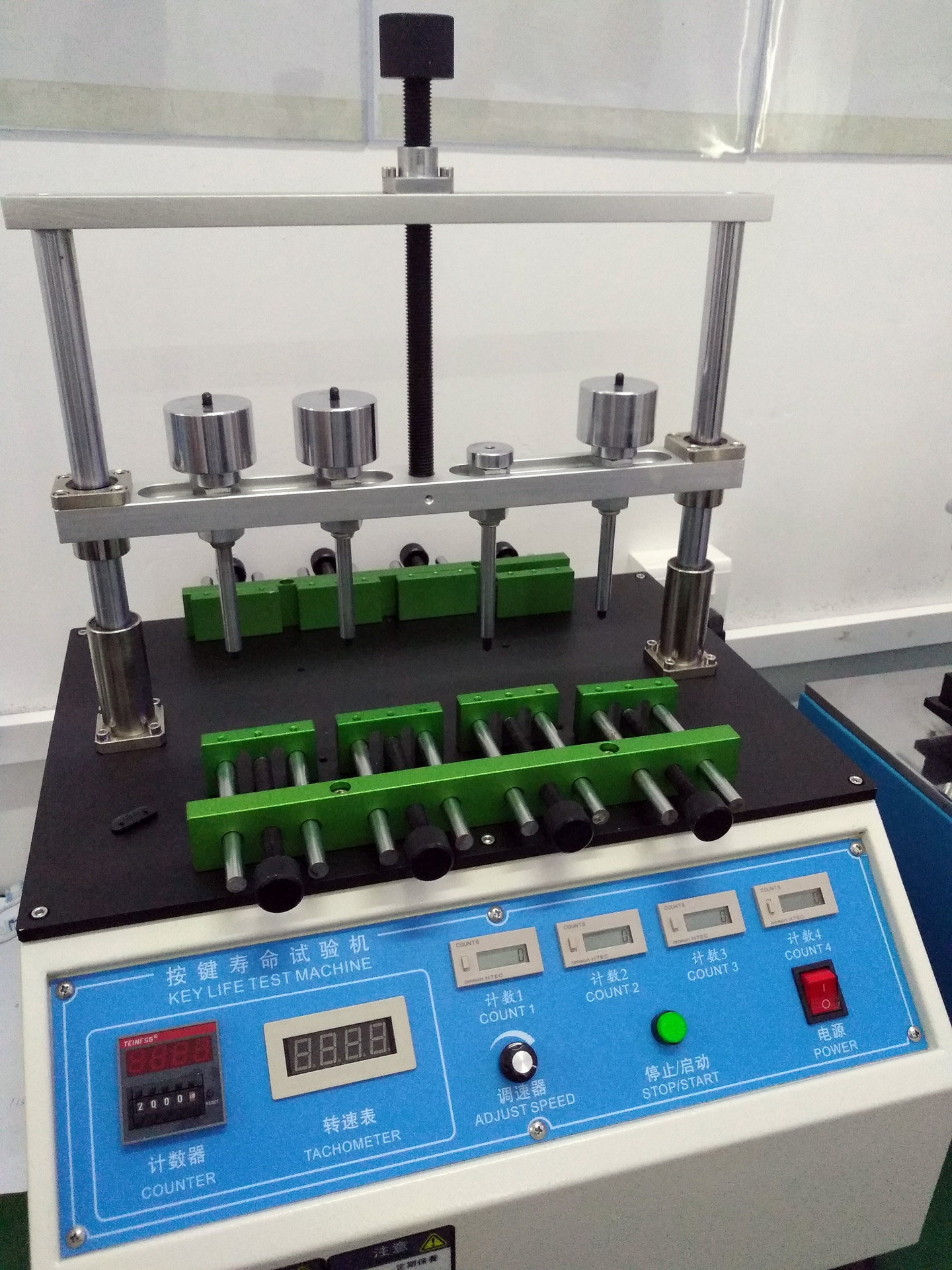

Through integrated water flosser accessory production, manufacturers can maintain unified quality standards throughout every stage of production. Testing protocols for accessories are aligned with main unit testing, ensuring that all components work harmoniously.

This alignment enhances product reliability, reduces returns, and provides distributors greater confidence in long-term brand quality — all while helping stabilize oral irrigator bulk pricing by minimizing defect-related losses.

Private label buyers and B2B distributors increasingly seek custom product configurations, from specialized nozzles to unique charging bases. With in-house water flosser accessory production, these customizations can achieve faster and at a lower cost.

Instead of waiting for third-party accessory suppliers to adjust designs or tooling, manufacturers can quickly modify molds, test new prototypes, and align accessory colors and branding with the client’s requirements.

This flexibility not only enhances your brand differentiation but also helps you negotiate better oral irrigator bulk pricing due to reduced customization overhead and shorter lead times.

Outsourced accessories often create bottlenecks in supply chains, especially when dealing with bulk orders or seasonal demand. A manufacturer managing its own water flosser accessory production avoids these risks by controlling both capacity and inventory.

By synchronizing accessory output with oral irrigator assembly, manufacturers can ensure that all necessary parts are available simultaneously — reducing backlogs and ensuring on-time delivery for wholesale clients.

This stability allows for predictable oral irrigator bulk pricing, helping distributors plan long-term procurement strategies with greater confidence and fewer cost fluctuations.

Integrated production is more than just a cost-saving measure — it’s a foundation for sustainable B2B relationships. Manufacturers with full accessory production capabilities tend to offer better communication, faster technical support, and long-term reliability.

For businesses investing in large-scale oral irrigator bulk pricing negotiations, choosing a manufacturer that manages water flosser accessory production internally ensures transparency in cost structure, easier process monitoring, and smoother cooperation over time.

This strategic partnership enables both parties to innovate together — whether through new nozzle technologies, energy-efficient charging systems, or upgraded user experience designs.

Integrated water flosser accessory production is a key factor in optimizing oral irrigator bulk pricing for B2B buyers. By consolidating accessory manufacturing within the same facility, companies benefit from cost efficiency, consistent quality, faster customization, and a more reliable supply chain.

For dental brands, e-commerce sellers, and importers aiming to scale their oral care business, partnering with a manufacturer that offers full in-house accessory production capabilities is not just an advantage — it’s a strategic investment in quality, speed, and long-term competitiveness.

? Looking for a trusted OEM/ODM partner with integrated water flosser accessory production and proven experience in optimizing bulk oral irrigator pricing? Contact our professional team today to learn how we can support your brand’s growth.

.jpg)

.jpg)

.jpg)

Proven Strategies to Unlock Premium Water Flosser Brands Positioning

Should You Partner with a Teeth Whitening Gel Manufacturing Expert?

.jpg)

long battery life electric toothbrush OEM | High-End Rechargeable Toothbrush Manufacturer

.jpg)

How Does a GMP Certified Toothbrush Factory Leverage Toothbrush Packaging Customization for Brand Appeal?

Identifying Chinese Electric Toothbrush Manufacturers That Listen and Improve With Your Feedback

AI Powered Toothbrush: Next-Generation OEM Technology

.jpg)

USB charging toothbrush wholesale supplier | OEM & Private Label Factory

.jpg)

electric toothbrush private label supplier | Custom Sonic Toothbrush Manufacturing

.jpg)

In-depth Analysis of the Logo Craftsmanship of Water Flossers

Can a Wireless Charging Toothbrush OEM Produce FDA Approved Electric Toothbrush Models Efficiently?

When Selecting Products for the US Market, What Kind of Aesthetic Electric Toothbrushes Are Most Popular?

5 Signs You Need to Replace Your Electric Toothbrush: Insights from an OEM Factory

Is Your Whitening Syringe Supplier Qualified for Home Use Whitening System Kits?

.jpg)

Light Decay Causing Gingival Discoloration?

Application of Water Transfer Printing and Thermal Transfer Printing on Electric Toothbrush Shell: 3D Texture and Wear Resistance Test

How does Brush Head Mold Design influence the effective integration of Food-grade Bristle Material?