In recent quality audits, water dispersion irregularities and jet scattering anomalies have become a recurring concern in oral irrigator systems. While consumers may initially tolerate these issues, the long-term impact on cleaning effectiveness, component durability, and user satisfaction cannot be ignored. Are these symptoms merely surface-level flaws, or do they signal deeper design or manufacturing challenges?

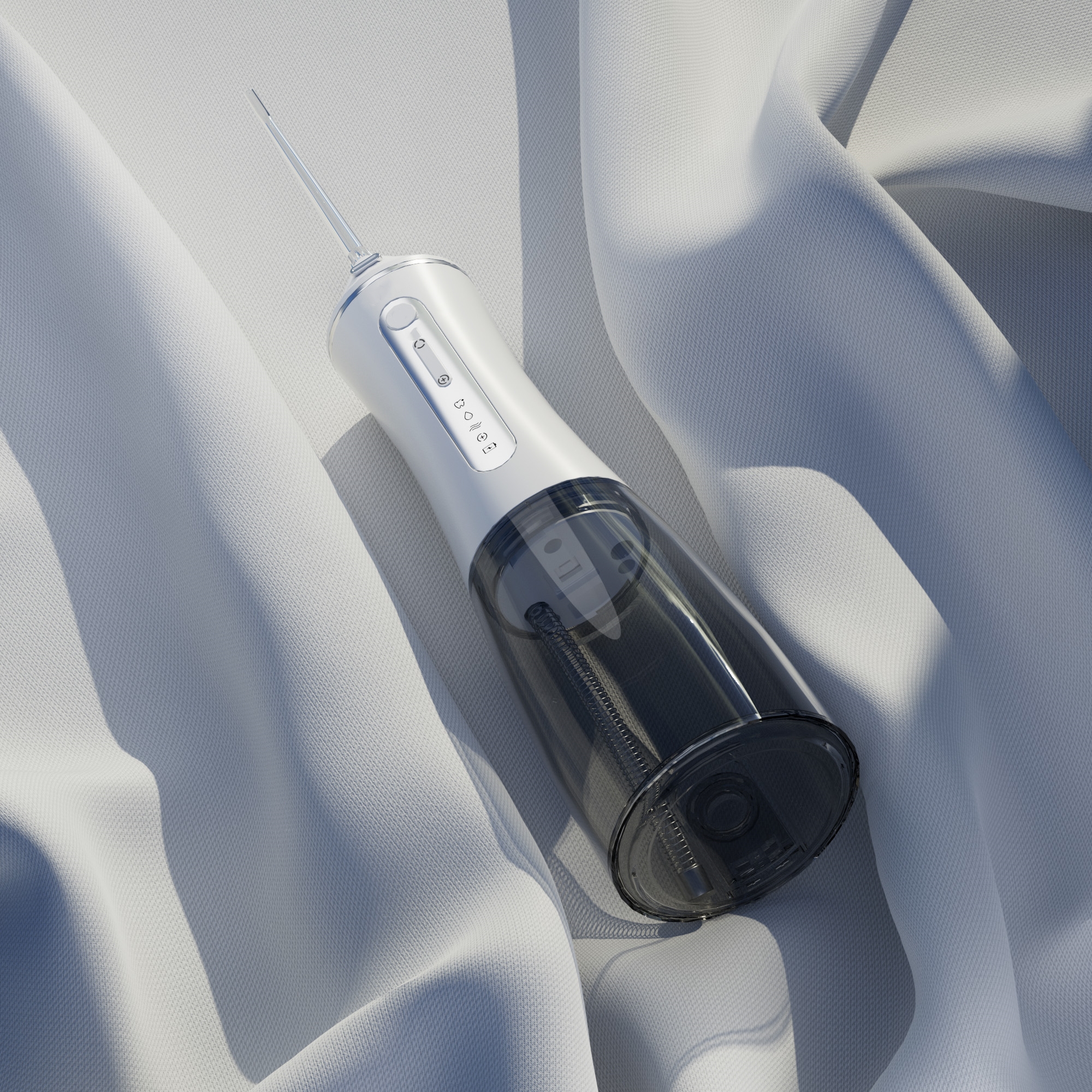

Water dispersion refers to the uncontrolled or non-uniform spreading of the water stream once it exits the nozzle. In precision-based devices such as dental irrigators, consistent flow is critical. When dispersion occurs, the water loses its directional focus, resulting in reduced impact pressure and ineffective debris removal.

Jet scattering typically accompanies water dispersion, manifesting as unpredictable or divergent spray paths. This may stem from several factors:

Such deviations can severely compromise a product’s perceived quality, especially in B2B scenarios involving dental professionals or healthcare retailers. Company web: https://www.powsmart.com/product/electric-toothbrush/

In many OEM/ODM designs, aesthetic nozzle shaping or overly compact dimensions may unintentionally increase the risk of jet scattering. It’s crucial to balance form with function—ensuring nozzle geometry is both ergonomic and fluid-optimized.

Even minor inconsistencies in injection molding or ultrasonic welding at the nozzle-head junction can create internal variances that alter flow dynamics. Tightening assembly tolerances and adopting in-line flow calibration during QC stages can significantly reduce jet scattering incidents.

While design and manufacturing account for a significant portion of these malfunctions, end-user cleaning and maintenance also play a role. Lack of descaling or improper storage can exacerbate water dispersion over time. B2B customers should consider including maintenance accessories or educational inserts as part of OEM packages.

So, is the combination of water dispersion and jet scattering fixable? Yes—but only with a systemic approach. Improvements across nozzle engineering, fluid channeling design, and QC protocols are essential. At the same time, clear communication to users on care practices helps maintain optimal performance throughout the product lifecycle.

Conclusion

Water dispersion and jet scattering are not just cosmetic issues—they signal potential gaps in design validation, fluid simulation, and process control. With proper corrective action, B2B manufacturers can not only eliminate these flaws but also elevate brand reliability in a highly competitive market. Contact us

.jpg)

.jpg)

Oral irrigator sourcing tips

Seeking an eco-friendly toothbrush from a bamboo toothbrush factory?

Compatibility of Water Flosser Accessories: How to Increase User’s Repurchase Rate Through Replaceable Nozzles?

What is the Least Damaging Way to Whiten Your Teeth with OEM Solutions?

.jpg)

Toothbrush Factory Audit Checklist – A Practical Guide for B2B Buyers

Is There a Way to Solve the Common Electric Toothbrush Water Ingress Problem?

Water Flosser vs. Traditional Dental Floss: A Manufacturing Perspective

How Does Integrated UV Sanitization Affect the Cartridge Replacement Cycle for Flossers?

Popular Electric Toothbrush Design Styles – OEM Trends for Brand Success

Discuss the application prospects of artificial intelligence, Internet of Things and other technologies in the field of water flosser

Can Waterproof IPX7 Design Protect a Hydro-dynamic Bearing in Humid Environments?

What is the Safest Teeth Whitening Method?

.jpg)

LED indicator water flosser supplier

Innovative Features That Make Your Electric Toothbrush Stand Out

Do Electric Toothbrush Heads Need Sterilization?

.jpg)

Seal Degradation Plus Circuit Shorting – Safety Risk?