When developing antibacterial oral care OEM products, ensuring the highest level of hygiene and safety is non-negotiable. Choosing the right sanitizing tech plays a critical role in both consumer trust and regulatory compliance. Among the leading methods available today, two technologies stand out: UVC vs. Ozone Sterilization. Both methods offer unique advantages, but which is the better option for OEM manufacturing needs based on efficacy and safety?

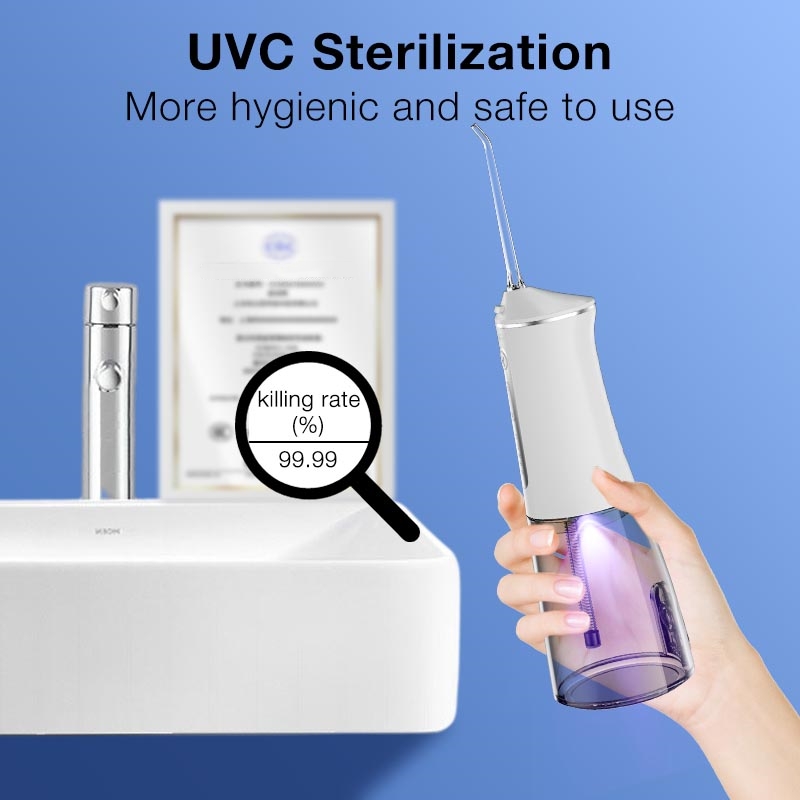

UVC Sterilization: Utilizes short-wavelength ultraviolet light to damage microbial DNA, effectively neutralizing bacteria, viruses, and fungi. Recent advances in UVC LED technology make this method more compact, energy-efficient, and eco-friendly compared to traditional mercury lamps.

Ozone Sterilization: Leverages ozone gas (O3), a powerful oxidizer, to disrupt microorganisms. Ozone has been widely used in water treatment and medical equipment sanitation due to its ability to penetrate crevices and hard-to-reach areas.

When considering UVC vs ozone sterilization, both demonstrate high levels of microbial reduction. However:

UVC LED technology offers targeted sterilization in seconds, making it suitable for smaller devices like toothbrush sanitizers or portable oral care tools.

Ozone can reach surfaces UVC light cannot directly touch, but it requires longer treatment times and controlled conditions.

For OEM manufacturing needs based on efficacy and safety, UVC often has the edge. Ozone, while powerful, can pose health risks if not fully contained or if residual ozone is inhaled by users. UVC, especially when integrated with smart sensors and shielding, can be designed for safe consumer use.

Today’s consumers demand eco-friendly, chemical-free solutions. UVC LED technology aligns with these preferences by avoiding harmful residues and providing a “clean tech” appeal. Ozone sterilization, while effective, may face pushback from safety-conscious customers in the oral care segment.

For antibacterial oral care OEM products such as toothbrush sanitizers, travel cases, or aligner cleaning devices:

UVC sterilization is ideal for compact, portable devices with frequent consumer use.

Ozone sterilization might be better suited for larger, centralized sterilization units where controlled environments are possible.

Ultimately, the decision between UVC vs ozone sterilization depends on your product goals, target market, and regulatory strategy. If your priority is consumer safety, fast sterilization, and eco-friendly design, UVC LED technology is likely the better fit. If you require deeper penetration and are designing professional-grade sanitation systems, ozone may still be valuable.

As the oral care industry advances, selecting the right sanitizing tech will define brand competitiveness. OEMs should weigh both efficacy and safety when integrating sterilization methods into their products. For many oral care applications, UVC LED technology stands out as the forward-looking solution, offering a balance of performance, safety, and consumer trust.

.jpg)

Advanced LED Sonic Toothbrush Manufacturer

Is the Specific LED Wavelength the Key to Being Truly Enamel Safe?

Analyze the Advantages and Disadvantages of Different Types of Flossing Technology According to Different User Needs

.jpg)

Electric Toothbrush Production Capacity for OEM & Wholesale Buyers

.jpg)

Perfect Pressure Every Time: Designing User-Friendly Water Flosser Settings for Your OEM Brand

.jpg)

Travel-Friendly Smart Toothbrush Supplier | Portable Oral Care Partner

.jpg)

Is Your Electric Toothbrush Losing Power Too Fast?

.jpg)

Whitening Gel Leakage Leads to Teeth Yellowing? Experts Issue Warning!

Private Label Electric Toothbrush & Water Flosser Manufacturing

Why Choose a Miami waterproof toothbrush for Miami beach toothbrush trips?

.jpg)

Is an LA affordable toothbrush available at LA store toothbrush locations?

How Does a UV Sanitizing Component Benefit from Medical-grade Material Construction?

IPX7 Waterproof Electric Toothbrush Customization for Global Markets

.jpg)

Bamboo Electric Toothbrush Handle OEM Manufacturer | Eco-friendly Design Solutions

.jpg)

Short Battery Life and Motor Overheating in Electric Toothbrushes: How to Enhance Durability?

Smart Toothbrush OEM Manufacturing for Tech Professionals