Why This Happens — And How Brands Can Prevent It Through Better Manufacturing One of the most frequent complaints from end-users of electric toothbrushes is: “The brush head was shedding bristles while brushing my teeth.” This seemingly small issue is a red flag for both consumers and oral care brands. Not only does it affect customer satisfaction, but it can also damage brand reputation and reduce repeat purchases. In this article, we’ll explore the real causes of shedding bristles, including poor brush head manufacturing, improper usage like brushing with too much force, and what oral care brands can do when sourcing the right electric toothbrush manufacturing partner.

When users experience bristles falling out during brushing, it typically points to one of two issues:

Manufacturing Defect: Low-quality filament anchoring, weak glue, or poor assembly in the brush head.

User Error: Aggressive brushing technique or using the brush head far beyond its recommended replacement period.

Regardless of the cause, it creates a negative perception of product quality. This is why both user education and manufacturing quality are critical.

From a manufacturing standpoint, poor brush head manufacturing is often the core issue behind bristle loss. Common manufacturing shortcomings include:

Inconsistent bristle tufting or trimming

Weak thermal fusion or gluing processes

Low-grade bristle materials

Insufficient quality control checkpoints

For oral care product brands, working with a factory that follows international standards (e.g., ISO 9001, CE, FDA for bristle safety) is essential. Choosing the right electric toothbrush manufacturing partner directly impacts long-term product reliability.

Consumers also contribute to the issue by brushing with too much force. Many believe that the harder they brush, the cleaner their teeth will be — which is not true and can lead to:\n- Gum irritation

Premature brush head wear

Loosening of bristles

Educating users on the right brushing method — using gentle pressure and letting the brush do the work — is key. For brands, including user manuals and app-based brushing tutorials can reduce this kind of misuse.

A well-designed electric toothbrush — especially its brush head — should be able to withstand daily usage for at least 3 months without bristle loss. This requires partnering with manufacturers that:

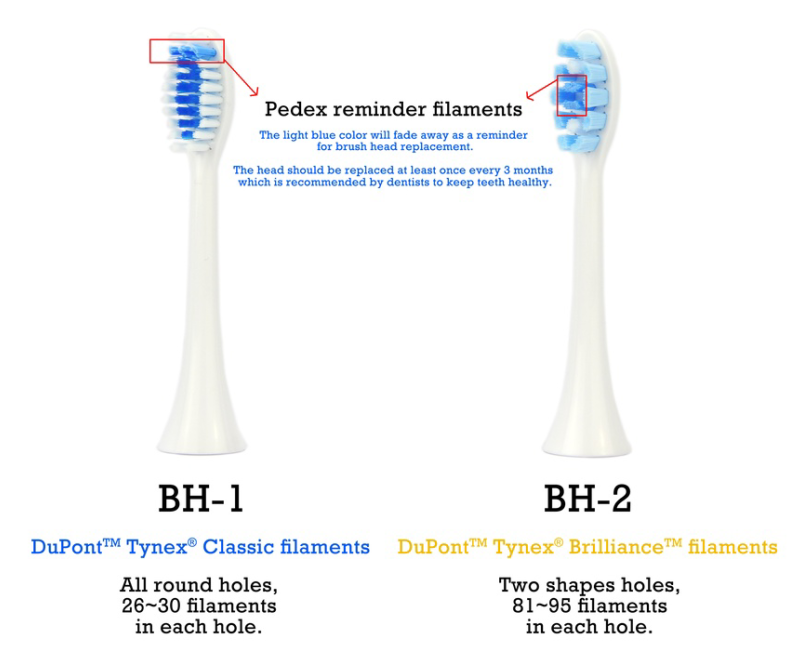

Use high-quality PBT or DuPont bristles

Follow precise tufting processes with automated machinery

Perform rigorous pull-testing and fatigue testing

Offer customization for bristle shape, density, and polishing finish

When brands prioritize electric toothbrush manufacturing quality, they drastically reduce customer complaints and enhance brand trust.

To recap:

✅ Shedding bristles is not just a user annoyance — it’s a brand risk

✅ It often stems from poor brush head manufacturing, but may also involve brushing with too much force

✅ Educating users on the right brushing method helps, but won’t fix a faulty product

✅ Working with a reliable electric toothbrush manufacturing partner ensures your product meets quality expectations

For oral care brands aiming to scale, now is the time to audit your supply chain, test your brush head quality, and find the right manufacturing partner who can uphold your brand’s reputation — not damage it.

.jpg)

Electric Toothbrush Warranty Policy for OEM & Private Label Brands

.jpg)

Sonic Toothbrush Cleaning Performance Engineering for OEM Manufacturing

.jpg)

Button Unresponsive with Flow Inconsistency – Fix?

How to choose an electric toothbrush for the First-Time User ?

.jpg)

Gingival Recession from Cervical Hypersensitivity – Irreversible?

.jpg)

Cleaning Residue Causing Tongue Irritation?

The Rising Market Potential of At-Home Teeth Whitening Devices

.jpg)

Alaska Electric Toothbrush for Travel

.jpg)

Antimicrobial Bristles & Precision Brush Head Molding for Electronic Toothbrush Production

Basic Steps and Tips for Oral Care

.jpg)

EU USB-C Regulation: How It Affects Electric Toothbrush Production

Key factors in selecting water flossers

-2-scaled.png)

Different Selling Points of Teeth Whitening Devices: Portable, APP-Linked, Gel Customization. Which Selling Point Attracts the Most Attention from Brands?

.jpg)

Kids Smart Sonic Toothbrush OEM | Professional Manufacturer for Global Brands

.jpg)

Can Short Tank Runtime Delay Oral Ulcer Care?

.jpg)

Hose Rupture and Gum Discomfort – Related?