For B2B buyers — safety managers, corporate procurement, occupational-health teams and OEM partners — the toothbrush you specify for industrial crews is not a trivial accessory. In Texas oilfields, oral hygiene affects comfort, communication, and even productivity. A purpose-built electric toothbrush marketed as an oil worker toothbrush can raise the bar on crew welfare and contribute to broader Texas worker dental safety programs. Below are six manufacturer-focused areas to consider when designing, spec’ing and selling an electric toothbrush for this demanding channel.

First, understand the work environment. Oilfield crews face long shifts, exposure to dust, hydrocarbon vapors, irregular meal schedules and limited access to dental care between rotations. Consequently, quick and effective at-shift cleaning helps reduce discomfort, bad breath and the likelihood of neglecting oral care altogether. Therefore, offering an oil worker toothbrush that actually gets used — because it is fast, effective and durable — becomes a simple but high-impact element of any Texas worker dental wellbeing program.

Next, durability is non-negotiable. Electric toothbrushes for oil workers must tolerate grit, splashes, oil and occasional drops. As a result, manufacturers should specify robust sealing, corrosion-resistant materials, and high waterproof ratings so the device keeps working after exposure. In other words, an electric toothbrush with industry-appropriate ruggedization will last longer in harsh Texas field conditions, lowering replacement cycles and warranty costs for employers. Company web: https://www.powsmart.com/

Moreover, battery life and charging matter in remote deployments. Long-run batteries, fast USB-C charging or vehicle-friendly charging adaptors let crews recharge between shifts. Additionally, consider low-maintenance charge docks or portable charging cases that can live in toolboxes or crew vehicles. Thus, ensuring reliable power means the oil worker toothbrush is ready when workers are — a critical operational requirement for any Texas worker dental initiative.

Furthermore, hygiene controls are central to occupational health. Design the electric handle and head with easy-to-clean materials, offer replaceable disposable brush heads, and consider optional UV or antimicrobial storage docks for shared crew facilities. From a B2B perspective, straightforward head-replacement logistics (bulk packs, subscription SKUs) reduce cross-contamination risks and simplify procurement for safety teams managing Texas worker dental protocols.

In addition, on-site use often happens with gloves, under time pressure, or in low-light conditions. Therefore, make the interface simple: large one- or two-button controls, tactile feedback, visible timers and audible cues. Also, a compact head profile and tapered bristles help reach interdental areas quickly without aggressive force. By prioritizing ergonomics, the oil worker toothbrush becomes genuinely usable during short breaks — improving compliance and overall oral hygiene.

Finally, manufacturers should help customers quantify value. Offer bulk-pack pricing, clinic-supply bundles (handles + head replenishment), branded kits for onboarding, and demo units for safety training. Moreover, present simple ROI metrics: lower sick days from dental discomfort, higher worker satisfaction, and fewer emergency dental calls during rotations. In this way, positioning an electric toothbrush as an oil worker toothbrush with clear support for Texas worker dental programs moves it from a perk to a justified occupational-safety purchase.

Conclusion:

An oil worker toothbrush that combines rugged hardware, long-lasting power, hygienic replaceability and field-friendly ergonomics is more than a convenience — it is a practical tool that supports Texas worker dental safety and occupational wellbeing. For manufacturers, the opportunity is clear: design with the environment in mind, simplify procurement, and demonstrate measurable value to safety managers. If you’d like, I can convert this into a product-spec checklist (IP rating, battery mAh, head-replacement cadence, suggested materials) or a one-page procurement brief tailored for oilfield safety teams. Contact us

.jpg)

Does Your Brush Fight Plaque Smartly?

Comparison of Sonic Vibration and Rotary Electric Toothbrush Technology

.jpg)

AI-Powered Electric Toothbrush OEM – Smart Oral-Care Solutions for Modern Brands

Teeth whitening kit: For Healthier, Whiter Teeth

.jpg)

Private Label Dental Products China | OEM & Wholesale

Why Choose a Quiet Water Flosser Supplier Sourced from a Cordless Water Flosser Factory?

Need a Wholesale Toothbrush Distributor Partnered with a Top Sonic Toothbrush Manufacturer China?

The Process of Developing a Private Electric Toothbrush

Why Pair Enamel Micro-abrasion With Chromophore Targeting Gel for Effective Teeth Whitening?

There Are Different Ways to Whiten Your Teeth, Which One Is Best for You?

Creating the Ultimate Oral Care Combo: Keys to the Best Toothbrush Water Flosser Design

.jpg)

Soft Bristle Toothbrush Bulk Order Solutions for Importers

.jpg)

Travel-Friendly Water Flosser: From Foldable Nozzles to Globally Voltage-Compatible Solutions

Teeth Whitening Kit OEM Manufacturing Compliance Standards

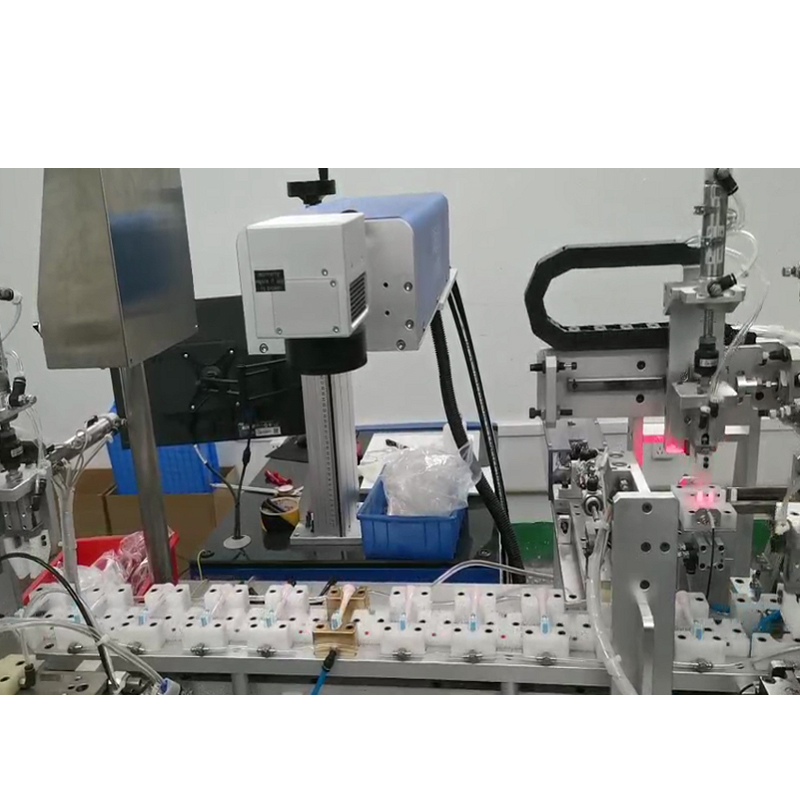

Electric Toothbrush Production Process Diagram: Complete Process from Injection Molding to Assembly and Key Points of Quality Inspection

.jpg)

Battery Overheating Inducing Ear Discomfort – Dangerous?