In dental device manufacturing and oral appliance engineering, occlusal interference and resulting jaw fatigue are critical yet often overlooked consequences of inadequate product design. When an appliance—whether a night guard, aligner, or occlusal splint—introduces unwanted bite interferences, it can lead to cumulative strain on the masticatory system. Could this be more than just a patient adaptation issue? Does it reflect a fundamental design flaw? This article explores that possibility in depth.

Occlusal interference occurs when a dental device disrupts the natural contact between upper and lower teeth during function or rest. Unlike physiologic occlusion, where contact is evenly distributed and harmonious, interference results in:

These small discrepancies, if consistent, can initiate or aggravate myofascial discomfort and alter the natural bite pattern.

When occlusal surfaces are poorly calibrated, they force the masticatory muscles to work harder to reach a comfortable bite. Over time, this triggers jaw fatigue, marked by:

While these symptoms may appear subjective, their underlying cause is often mechanical, rooted in how the device is engineered and fitted.

Several product design choices directly impact whether occlusal interference occurs:

Failure to anticipate these during design and production can introduce functional conflicts that patients experience as fatigue or pain.

For years, jaw fatigue following use of occlusal devices has been dismissed as temporary adaptation. However, mounting clinical evidence shows that prolonged fatigue:

This positions fatigue not as a harmless byproduct but a warning sign—possibly signaling a mismatch between device mechanics and human physiology.

To avoid jaw fatigue caused by occlusal interference, manufacturers should integrate the following design optimizations:

Proactive innovation at the CAD/CAM stage can significantly reduce user discomfort while enhancing clinical outcomes.

When occlusal interference leads to jaw fatigue, the issue cannot solely be attributed to user tolerance or practitioner error. Often, the root lies in insufficient attention to dynamic occlusion and load management during product development.

For B2B clients, this means scrutinizing whether your occlusal devices are engineered for precision, comfort, and long-term safety. At scale, even small design misalignments can result in widespread user dissatisfaction—or worse, compromised oral health.

Looking to optimize your oral appliance designs to eliminate such flaws? Contact our development team to collaborate on next-generation solutions that deliver both functionality and biomechanical harmony. Contact Kiwibird

How Can You Turn Your Users into Loyal Users of Your Oral Care Brand?

The importance of the roundness of toothbrush bristles

What Competitive Oral Care Products Are Needed in the Highly Competitive Dental Care Market?

Cheap vs High-End Electric Toothbrushes : 5 Key Differences You Should Know

.jpg)

Pressure Sensor Failure with Taste Distortion – Related?

.jpg)

Sync Disruption with Tray Deformation – Tech Failure?

.jpg)

How to Build a Differentiated Oral Care Brand?

.jpg)

Swivel Blockage Leading to Saliva Depletion – Preventable?

.jpg)

Biofilm Regrowth Inducing pH Imbalance – Vicious Cycle?

.jpg)

Small-Batch Customization Orders: How Low MOQ Opens Doors for New Oral Care Brands

.jpg)

Bristle Splaying Worsening Demineralization Zones – Negligence?

High After-Sales Costs: How They Cripple Oral Care Brand Profits & Reputation

Oral health facts & tips: Teeth whitening

How Long Does It Take for a Teeth Whitening Device to Show Results?

.jpg)

Gel Crystallization with Gingival Discoloration – Alarming?

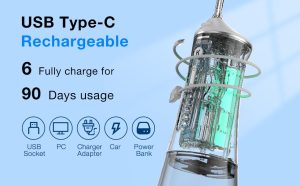

Which Charging Method for Electric Toothbrushes Is Better and Has a Lower Charging Failure Rate?