When users experience a loose brush head, they often overlook its downstream impact—specifically how unstable connections can diminish low filament roundness, undermining both cleaning performance and user safety. For B2B manufacturers, recognizing and addressing this hidden quality trap is critical to delivering reliable electric toothbrushes.

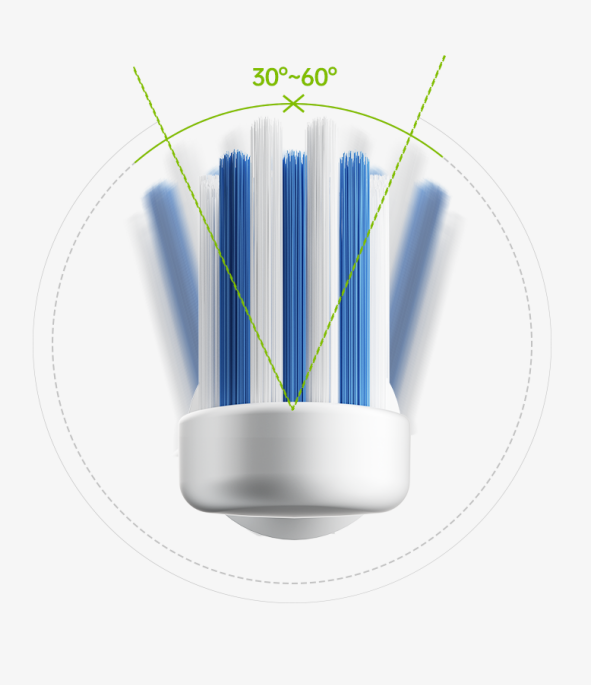

First, any micro-movement at the head-handle junction forces bristles to bend unevenly:

Consequently, head stability is the foundation for maintaining filament shape.

Moreover, bristles that lose their circular cross-section create multiple issues:

Therefore, preserving filament geometry is essential for both efficacy and comfort.Company web:https://www.powsmart.com/product/electric-toothbrush/

To eliminate this dual failure mode, manufacturers should optimize both assembly and materials:

A combined approach fortifies both the head coupling and filament integrity.

Additionally, a robust quality regime must span every production stage:

Integrating these checks into your QMS catches defects before they reach the market.

Equally important is empowering your distribution and service network:

By equipping partners, you ensure consistent quality at every touchpoint.

Finally, use field data to drive product evolution:

A feedback-driven process guarantees your toothbrushes become more robust with each generation.

Conclusion

A seemingly minor loose brush head can trigger low filament roundness, setting off a chain of cleaning inefficiencies and user discomfort. By synchronizing threaded interfaces, dampening solutions, filament materials, stringent QA, partner training, and iterative development, B2B manufacturers can overcome this quality trap and deliver truly reliable electric toothbrushes. Contact us to co-create your next-generation, high-performance oral-care products!

.jpg)

Is Chewing Ice Bad for Your Teeth? The Hidden Dangers Explained

What Brush Head types are Suitable for You?

.jpg)

What Should Be Noted When Developing or Selecting Children’s Oral Care Products?

.jpg)

Rechargeable Sonic Toothbrush Wholesale | High-Performance Oral Care Supplier

.jpg)

How to Measure Bio-film Removal Efficiency with a Plaque Disclosure Indicator?

.jpg)

Kids Electric Toothbrush Hyderabad | Fun & Gentle Care

.jpg)

Jaw Fatigue After Taste Alteration – Coincidence?

.jpg)

Managing LED Whitening Device Production?

OEM Electric Toothbrush Quality Manufacturing in USA Texas

.jpg)

BPA Free Electric Toothbrush Bulk Supply | Health-Focused OEM Solutions

The Core Component of an Electric Toothbrush – electric Motors

.jpg)

pH Imbalance with Biofilm Regrowth – Vicious Cycle?

.jpg)

Sustainable Electric Toothbrush Factory China | Eco-Friendly Oral Care

.jpg)

What’s Next in Smart Toothbrush Technology for Advanced Dental Health Monitoring?

.webp)

How Do Electric Toothbrush Market Trends Influence Electric Toothbrush Supplier Certification?

.jpg)

Can Osmotic Pressure Regulation Enhance Jet Stream Collimation in Oral Irrigators?