In many industrial applications, persistent Noise Amplification and recurring Vibration Issues not only create operational inefficiencies but also potentially damage equipment and compromise product quality. These challenges often emerge from a complex interplay of design, materials, and external factors, and their impact on machinery performance can be significant. In this blog, we will delve into the root causes behind these phenomena, examine their broader effects on operations, and suggest strategic measures to mitigate them effectively.

As industries push toward higher productivity and precision, controlling environmental disturbances becomes critical. Unwanted noise and vibration not only disrupt workflow but can also indicate underlying problems within systems. When Noise Amplification occurs, it often signifies that sound energy is being magnified rather than dampened, leading to ergonomic and mechanical strains. Similarly, persistent Vibration Issues can cause premature wear on components and lead to costly maintenance downtime. Recognizing and addressing these challenges is vital in preserving operational reliability and ensuring safety.

To solve these challenges, it is important to analyze their origins. Several factors contribute to Noise Amplification:

Likewise, Vibration Issues can originate from:

Understanding these foundational causes is the first step toward implementing robust solutions.

The repercussions of unmanaged noise and vibration are both broad and deep:

Thus, addressing these issues is not only about improving performance but also about ensuring long-term sustainability and workplace safety. Web:https://www.powsmart.com/product/electric-toothbrush/

Effective diagnosis is essential for targeted intervention. Manufacturers should consider the following techniques:

Combining these diagnostic methods creates a comprehensive picture of where and why the issues are occurring.

Once the sources of noise and vibration are identified, manufacturers can adopt the following strategies:

These measures, when integrated, can significantly reduce noise levels and vibrations, ensuring smoother, more reliable operations.

The challenge of managing Noise Amplification and Vibration Issues is an ongoing one, but emerging technologies offer promising solutions:

By embracing these future innovations, manufacturers can continuously improve product reliability and remain competitive in the global market.

Conclusion

Addressing Noise Amplification and Vibration Issues is essential for maintaining high standards of operational efficiency and product durability. By understanding the causes, employing advanced diagnostic tools, and implementing robust mitigation strategies, manufacturers can protect their equipment from premature wear and operational disturbances. Continuous innovation and a commitment to quality control will ensure that systems remain stable, safe, and efficient in an ever-evolving industrial landscape.

Interested in exploring how advanced technologies can help reduce noise and vibration in your systems? Contact us today to learn more about our tailored solutions and expert services.

How Does Maintenance Difficulty Worsen Enamel Weakness?

EU vs. US Whitening Gel Regulations for Global Brands

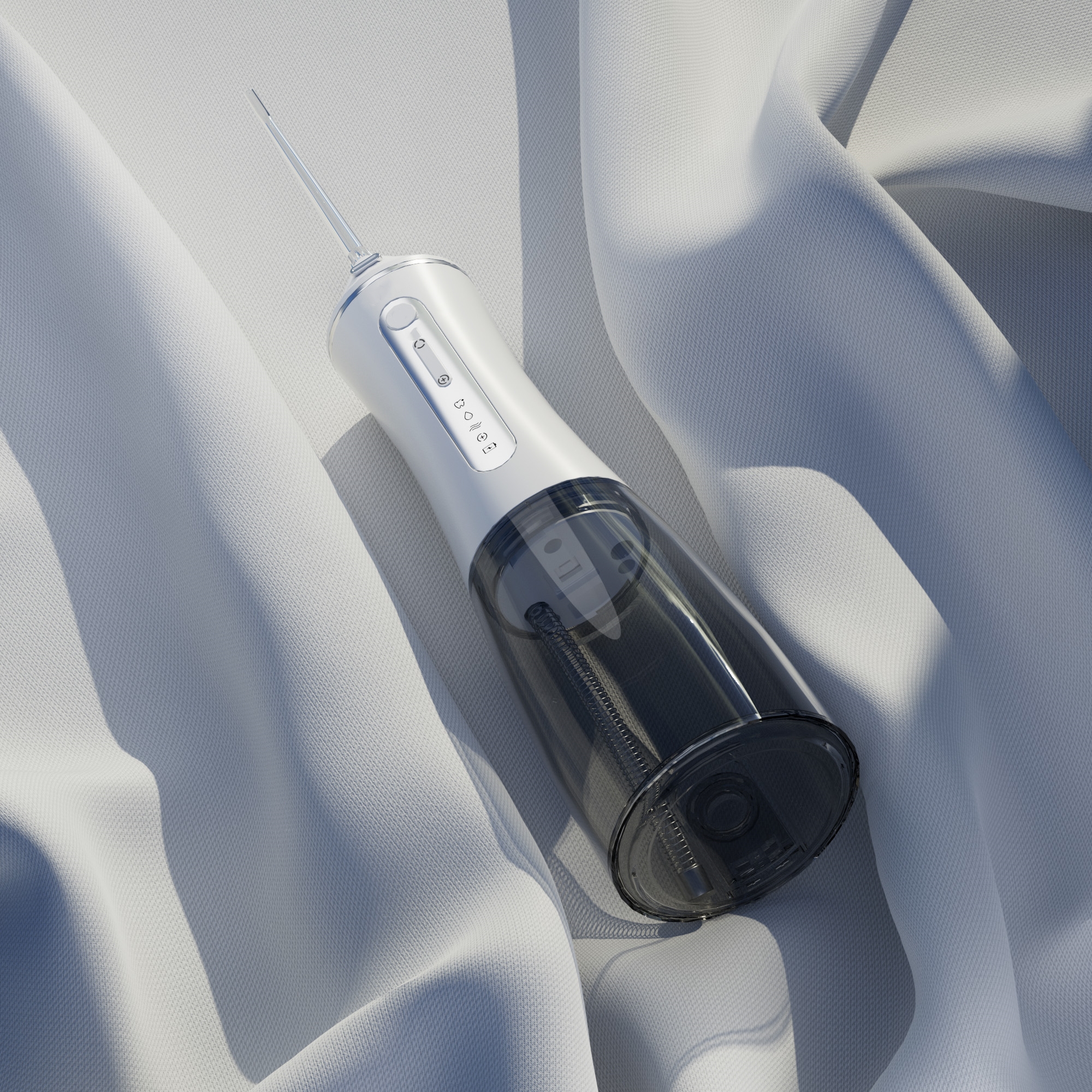

Compatibility of Water Flosser Accessories: How to Increase User’s Repurchase Rate Through Replaceable Nozzles?

Can Chemical Burns from Whitening Kits Cause Crown Discoloration?

-2-scaled.png)

Different Selling Points of Teeth Whitening Devices: Portable, APP-Linked, Gel Customization. Which Selling Point Attracts the Most Attention from Brands?

How to Fix LCD Glitches and Sensor Errors?

Understanding and Treating Gum Bleeding When Brushing

Can Blue Light Teeth Whitening Devices and Whitening Gels Be Used During Pregnancy?

Can Brush Head Rotation Cause Enamel Erosion?

Does Cold-Light Teeth Whitening Aggravate Enamel Wear?

Child Compatibility Meets Cold Light Sensitivity: Safe?

Why Is Allergen Testing Critical for Post-Whitening Diets?

What is the Electric Toothbrush Market Forecast?

A Must-Have Guide for Brands to Deal with Water Leakage, Unstable Pressure, and charging failure repair of Water Flosser

.jpg)

A Guide to Designing Good-Looking Electric Toothbrush: How Can Macaron Colors + APP Interconnection Increase Product Premium?

Are Button Malfunctions and Circuit Shorts the Cause?

electric toothbrush heads Regular Clean

electric toothbrush heads Ultra Soft

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Customization Teeth Whitening Gel

Private Label Whitening Gel

electric toothbrush heads Deep Clean

electric toothbrush heads Charcoal Infuse-Round

Electric toothbrush heads Charcoal Infused-Diamond

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638