Excessive gel leakage from ill-fitting trays or low-viscosity formulations can cause whitening agents to pool inconsistently—ironically triggering teeth yellowing instead of brightening. To help B2B manufacturers and channel partners safeguard end-user outcomes, our experts examine six critical facets of this hidden hazard and recommend actionable solutions.

First, understanding why gel escapes its intended boundaries is key:

Identifying these root causes enables targeted design improvements.

Next, examine the mechanism linking leakage to discoloration:

This cascade of effects undermines the “one-size-fits-all” whitening promise.

Moreover, unchecked gel leakage impacts both users and brands:

Proactive mitigation is therefore essential to maintain market competitiveness.

To control leakage at the source, incorporate these refinements:

Combining precision trays with smart delivery tames gel migration.

Beyond design, robust QMS and enablement keep standards high:

Empowering your channels turns product specs into real-world success.

Finally, an iterative feedback loop drives lasting results:

By closing the loop between field performance and R&D, you ensure ever-improving whitening reliability—and guard against teeth yellowing surprises.

Conclusion

While whitening gels promise dazzling smiles, uncontrolled gel leakage can reverse results into uneven bleaching and teeth yellowing. By addressing tray design, gel rheology, rigorous QC, partner training, and continuous feedback, B2B manufacturers can deliver truly predictable whitening outcomes. Contact us to co-develop leak-resistant, high-performance whitening systems that delight both clinicians and end users.

.jpg)

.jpg)

Electric Toothbrush for IT Employees | Tech-Friendly Oral Care

.jpg)

Electric Toothbrush Gift Set Supplier

.jpg)

Charging Corrosion with Mucosal Lesions – Fatal?

.jpg)

low noise electric toothbrush OEM factory | Quiet Sonic Manufacturer

.jpg)

Electric Toothbrush Private Label Supplier | Build Your Custom Brand Line

.jpg)

Frequent Allergy Reactions to Whitening Kits: Is Cold-Light Technology to Blame?

Why Should You Cover Your Toothbrush in the Bathroom? Hygiene Insights from Manufacturers

.jpg)

Compact Whitening Device Wholesale for Global Distributors and Brands

AI Powered Toothbrush: Next-Generation OEM Technology

.jpg)

Adapter Overheating with Circuit Shorting – Fire Risk?

.jpg)

Split Bristles Linked to Enamel Cracks? 90% of Users Ignore This Danger!

What makes Portable Flosser Design dependent on integrating a Quiet Flosser Motor?

How Does Supply Chain Logistics Affect the Integration of a Battery Management System?

-2-scaled.png)

Small Business – Health & Household Oral Care Products

Does Continuous Bluetooth Connectivity Significantly Affect Overall Battery Life of Electric Toothbrushes?

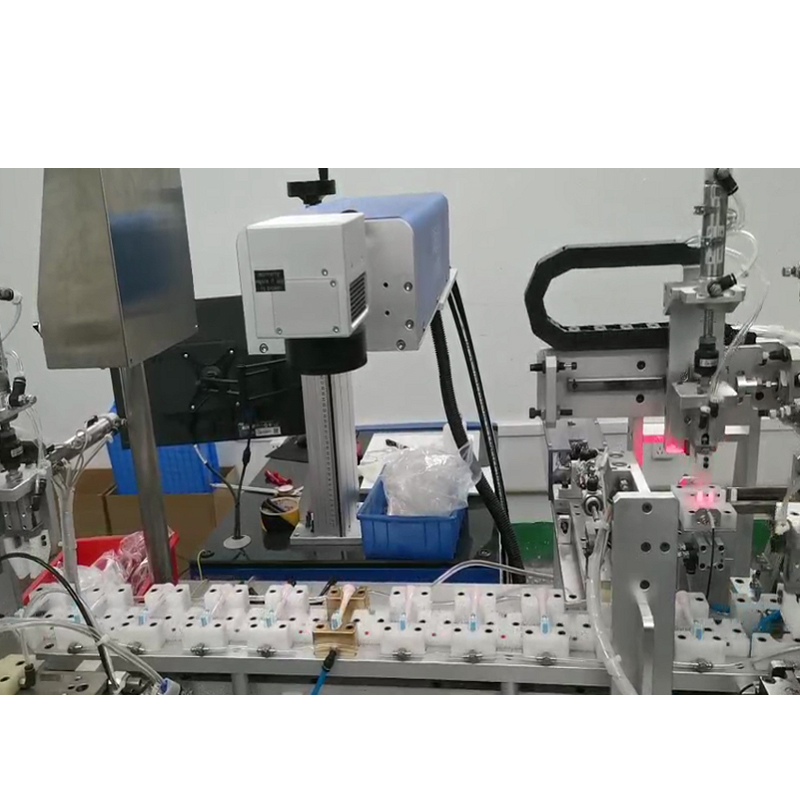

Electric Toothbrush Laser Engraving LOGO Process: How to Set the Depth, Speed and Power Parameters?