The electric toothbrush market is growing rapidly, and consumers are demanding not only high-performance devices but also aesthetically pleasing and durable designs. As manufacturers, finding the right balance between aesthetics and durability in electric toothbrush precision mold manufacturing is crucial.

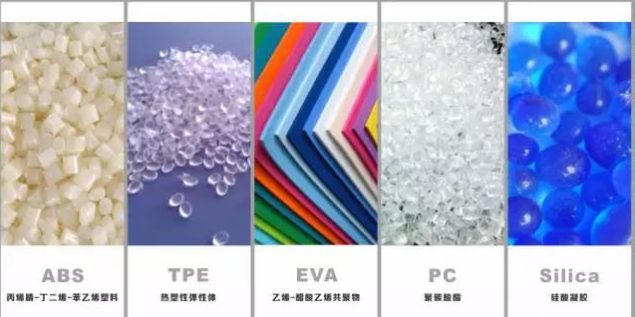

This blog explores how to achieve high-quality electric toothbrush handle shell customization, the best material choices like ABS/PP material, and how industrial design support plays a key role in developing innovative, durable, and visually appealing products.

Choosing the right material is the foundation of manufacturing durable and aesthetically pleasing toothbrush shells.

ABS (Acrylonitrile Butadiene Styrene):

High impact resistance and durability

Smooth surface finish, ideal for premium design

Excellent mechanical strength for long-term use

PP (Polypropylene):

Lightweight and resistant to moisture

High flexibility and chemical resistance

Cost-effective for large-scale production

By selecting the appropriate ABS/PP material, manufacturers can ensure that the electric toothbrush shell meets both design and durability requirements.

Electric toothbrush precision mold technology is essential for achieving high-quality production. The precision molding process ensures:

Consistency in design: Every toothbrush handle shell must have a uniform shape and finish.

Minimized defects: Advanced molding techniques reduce warping, shrinkage, and surface imperfections.

Enhanced production efficiency: High-precision molds lower waste and improve overall yield.

Investing in high-quality precision mold technology ensures a perfect balance between functionality and aesthetics.

With increasing competition in the oral care industry, electric toothbrush handle shell customization is a key differentiator. Manufacturers can offer:

Custom colors and textures to enhance brand identity

Ergonomic designs that improve grip and user experience

Waterproof coatings and anti-slip finishes for better durability

Customization not only meets consumer preferences but also enhances the overall value of the product.

Successful electric toothbrush manufacturing goes beyond just material selection and molding—it requires strong industrial design support. Design teams collaborate with engineers to:

Optimize shell thickness for maximum durability

Ensure a sleek, modern aesthetic that appeals to customers

Integrate seamless assembly for better structural integrity

This partnership between design and engineering ensures the final product is both visually appealing and structurally sound.

To guarantee the durability of an electric toothbrush shell, manufacturers must conduct rigorous testing, including:

Drop tests to assess impact resistance

Heat and moisture resistance tests for long-term usability

Chemical resistance tests to prevent material degradation

Comprehensive quality control ensures that the toothbrush shell withstands daily usage without compromising its appearance or function.

Balancing aesthetics and durability in electric toothbrush precision mold manufacturing requires a combination of:

High-quality ABS/PP material selection

Advanced molding technology for consistency

Customizable designs to enhance brand differentiation

Strong industrial design support for a superior user experience

Durability testing to maintain long-term performance

By integrating these elements, manufacturers can develop electric toothbrush handle shells that are both visually appealing and built to last, ensuring a competitive edge in the market.

If you’re looking for expert guidance in electric toothbrush handle shell customization, our team provides complete industrial design support and precision manufacturing solutions. Contact us today to explore your options!

What Should I Do If I Produce a Lot of Saliva When Using a Teeth Whitening Device?

Do You Know What PAP+ Is? Why Is It So Popular in Teeth Whitening?

Electric Toothbrush Quality Control: The Whole Process from Production to Delivery

.jpg)

Crown Compatibility with Pressure Sensors Tech?

.jpg)

Travel-Friendly Water Flosser: From Foldable Nozzles to Globally Voltage-Compatible Solutions

Sustainable Materials for Eco-Conscious Oral Care OEM Manufacturing

Concerned About High Toothbrush Minimum Order Quantity?

What Are the Specific Performances After Water Ingress of the Automatic Boot of the Electric Toothbrush?

Prediction of the Future Development Trend of the Water Flosser Industry: Technological Innovation and Market Opportunities

Electric toothbrushes vs. other oral care tools

Professional vs. Home Use: Key Technical Differences in Teeth Whitening Blue Lights

Understanding MOQ Variations for Custom Electric Toothbrush Colors

Can a Bangalore AI toothbrush boost your Efficient brushing tech routine?

UV Mode in Water Flossers: A Key Feature for Modern OEM Oral Care Products

.jpg)

ADA FDA dental product certifications

Navigating Toothbrush Import Regulations: What Every Buyer Should Know?