As oral care devices become more personalized and technology-driven, electric toothbrush head customization is gaining traction, especially among brand owners and private label clients. For OEMs and B2B buyers, understanding the range of customization options available is essential to meeting diverse consumer demands.

In this blog, we explore the complete toothbrush head OEM solution, covering materials, structure, compatibility, and performance — to help you develop a product line that stands out in today’s competitive oral care market.

A successful toothbrush head OEM project starts with selecting the right materials and defining core parameters. Manufacturers can customize:

Head shape (round, oval, diamond-cut)

Base material (ABS, PP, or eco-friendly alternatives)

Color schemes to align with brand identity

Logo imprinting on the neck or base of the brush head

By offering complete control over design and aesthetics, OEM partners can help businesses establish unique product lines.

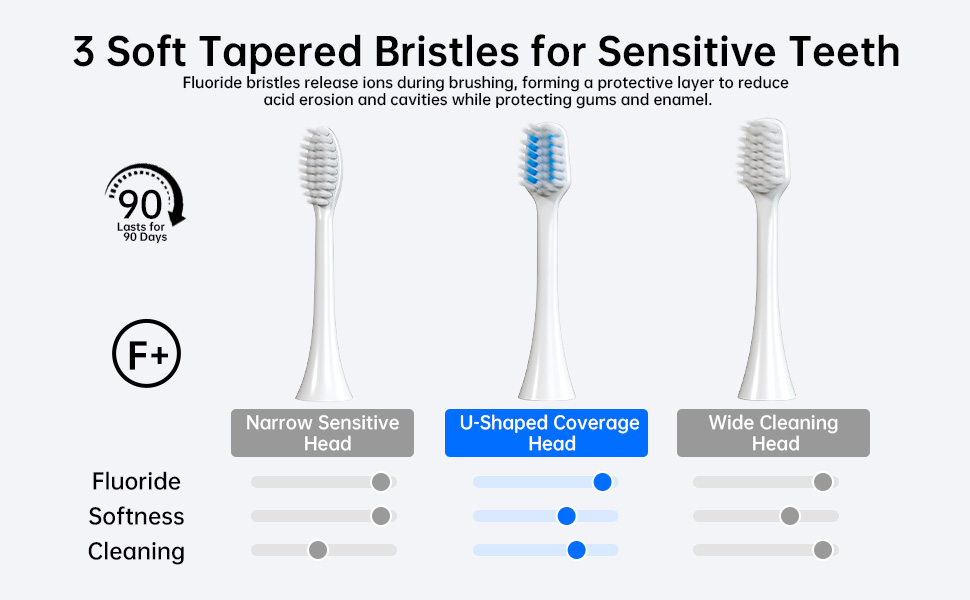

The type of bristles used greatly influences brushing efficiency and comfort. Customizing nylon wire specifications involves selecting:

Diameter (commonly 0.15mm to 0.22mm)

Hardness (soft, medium, or hard)

Tip processing (tapered, end-rounded, polished)

Material types (Dupont Tynex®, PBT, antibacterial filaments)

Adjusting bristle specs not only supports brand differentiation but also tailors the user experience for different demographics — such as sensitive teeth users or orthodontic patients.

The bristle implant aperture design directly impacts the density, layout, and lifespan of the brush head. Customization options include:

Number and shape of holes

Spacing to optimize plaque removal

Directional layout (e.g., crisscross or wave pattern)

A well-designed implant aperture ensures effective brushing while maintaining structural integrity, even under high-frequency vibrations.

For brands producing compatible brush heads for major electric toothbrush systems (such as Philips Sonicare®, Oral-B®, etc.), a critical step is the brush head compatibility test. This includes:

Ensuring secure attachment and detachment

Verifying vibration transmission efficiency

Checking for noise or motor drag during operation

Compatibility testing ensures seamless integration across devices, enhancing customer satisfaction and reducing returns.

Whether you’re targeting entry-level consumers or premium users, a flexible electric toothbrush head customization range enables you to design products that match functional requirements and market positioning. From nylon wire specifications to bristle implant aperture design and full OEM solutions, our engineering and quality teams support every step of the process.

By conducting a thorough brush head compatibility test and offering scalable OEM customization, we ensure that your product not only meets industry standards — but exceeds customer expectations.

Need a custom solution? Contact us today to explore your options in electric toothbrush head OEM manufacturing.https://www.powsmart.com/oral-care-products-private-label/

.jpg)

Professional IPX7 Toothbrush Supplier for Global Importers

.jpg)

How Do Motor Noise and Pump Noise Disrupt User Experience?

.jpg)

What’s Next in Smart Toothbrush Technology for Advanced Dental Health Monitoring?

-2-scaled.png)

The Scientific Principle of Red and Blue Light Teeth Whitening Device: How Can 460nm Blue Light and 630nm Red Light Safely Whiten Teeth?

Can a Long Battery Life Toothbrush Attract Global Buyers with Multi-language Manual Customization?

How to Ensure That a Factory’s Quality Control Process is Strict and Standardized

Frequency and Tips for Using Your At-Home Mouthpiece Recommended by Your Dentist

Factory Tells You If Electric Toothbrushes Turn On Automatically at Night – What Can We Do?

.jpg)

As the global dentist’s first choice, where is Oral-B’s professionalism reflected?

What is the general lifespan of electric toothbrush

How Does Bulk Toothbrush Heads Wholesale Benefit from Innovative Electric Toothbrush Mold Design?

The Higher the Frequency of the Electric Toothbrush, the Better the Cleaning Ability?

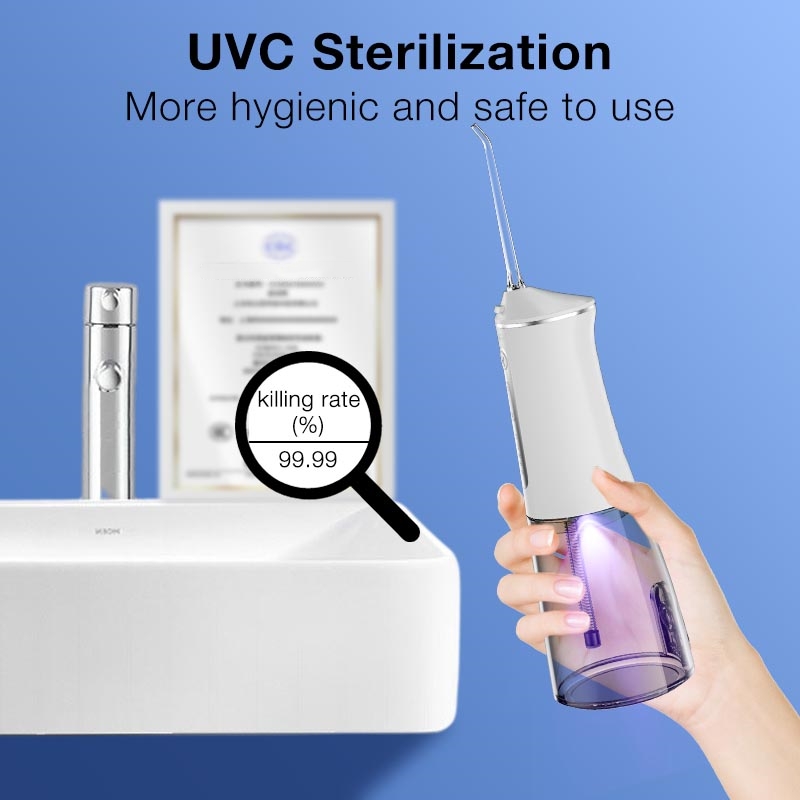

What is the Most Important Test Process in the Production of Water Flosser?

Key Factors Affecting Electric Toothbrush Cleaning Performance

Oral Irrigator Product Upgrade: Revolutionize Dental Care with Advanced Water Flossing Tech

.jpg)

Gentle Electric Toothbrush for Sensitive Aging Gums