As the demand for high-performance electric toothbrushes continues to grow, consumers are not only looking for superior cleaning efficiency but also for a quieter and more comfortable brushing experience. A key technological breakthrough in achieving this lies in the Gearbox Assembly, which plays a crucial role in optimizing power transmission while incorporating Noise Reduction techniques.

In this blog, we will explore the significance of Gearbox Assembly in electric toothbrushes, focusing on its impact on Noise Reduction, durability, and overall user experience. Analyzing six key technologies reveals how advanced engineering revolutionizes silent, high-efficiency electric toothbrushes.

The Gearbox Assembly is the heart of an electric toothbrush, responsible for converting motor power into precise oscillations or vibrations that drive the brush head. A well-engineered gearbox ensures smooth power transmission, minimizing energy loss and optimizing brushing effectiveness.

Traditional gear mechanisms often produce unwanted noise and vibrations, which can lead to discomfort during brushing. By refining the Gearbox Assembly design, manufacturers can enhance efficiency while addressing these common user concerns.

One of the biggest challenges in electric toothbrush engineering is controlling noise levels. Without proper Noise Reduction measures, the high-speed rotation of the motor and gears can create excessive vibrations and sound, affecting the user’s experience—especially in quiet environments such as early mornings or late at night.

To counteract this, advanced Gearbox Assembly solutions integrate noise-dampening materials, precision-cut gears, and optimized lubrication systems to significantly lower noise output. By reducing mechanical friction and unwanted vibrations, manufacturers can achieve a near-silent brushing experience while maintaining powerful cleaning performance.

Achieving Noise Reduction starts at the design level. Traditional gear mechanisms use standard plastic/metal gears, generating excess noise from friction and misalignment.

By employing high-precision molded gears with optimized tooth profiles, manufacturers can ensure smoother interaction between gear components. Additionally, using materials with enhanced acoustic dampening properties further minimizes operational noise. This meticulous design approach results in an ultra-quiet brushing experience without compromising performance.

The choice of materials in the Gearbox Assembly is another crucial factor affecting both durability and Noise Reduction. Modern electric toothbrush gearboxes utilize:

By integrating these material innovations, manufacturers can extend product lifespan while ensuring a more pleasant user experience.

Beyond just noise, excessive vibrations can also negatively impact the user experience. Without proper vibration control, an electric toothbrush can feel harsh on the gums and teeth.

Advanced Gearbox Assembly technology helps mitigate this issue by:

These enhancements boost brushing comfort and extend toothbrush longevity by minimizing mechanical wear and tear.

Looking ahead, the evolution of Gearbox Assembly in electric toothbrushes will continue to focus on precision engineering and Noise Reduction innovations. Emerging trends include:

As consumer expectations for a quieter and more efficient brushing experience rise, manufacturers must remain at the forefront of innovation, refining Gearbox Assembly designs to push the boundaries of Noise Reduction and overall performance.

The Gearbox Assembly is a fundamental component in the design and function of modern electric toothbrushes. By prioritizing Noise Reduction, material optimization, and vibration control, manufacturers can develop high-performance toothbrushes that deliver an ultra-quiet yet powerful cleaning experience.

As technology advances, continued innovation in Gearbox Assembly will pave the way for smarter, more efficient, and virtually silent electric toothbrushes—enhancing both user satisfaction and market competitiveness.https://www.powsmart.com/about-powsmart/

Are IPX7 Kids Brushes Truly Waterproof?

How Important Is Waterproof Testing for Electric Toothbrushes?

.jpg)

Water Spray Scattering Plus Whitening Rebound – Design Flaw?

Highly Effective Electric Toothbrush Changes Your Oral Care Habits

The Science of Light: How Red & Blue LED Technology Enhances Modern Oral Care

How Can Oral Care Product Brands Improve Customer Trust Through Content Marketing?

.jpg)

Multi-Mode Electric Toothbrush Manufacturer for OEM Oral Care Projects

How Does Colorimeter Calibration Ensure Accurate Opalescence Enhancement in Whitening Products?

Why Is It Important to Use a Water Flosser Instead of Dental Floss?

Analysis of the Core Competitiveness of Electric Toothbrushes: How to Win the Market Through Technological Innovation?

.jpg)

Allergic Reactions and Taste Alteration – Whitening’s Hidden Cost?

.jpg)

Why Dentist Consultations Mitigate Home Treatment Risks?

.jpg)

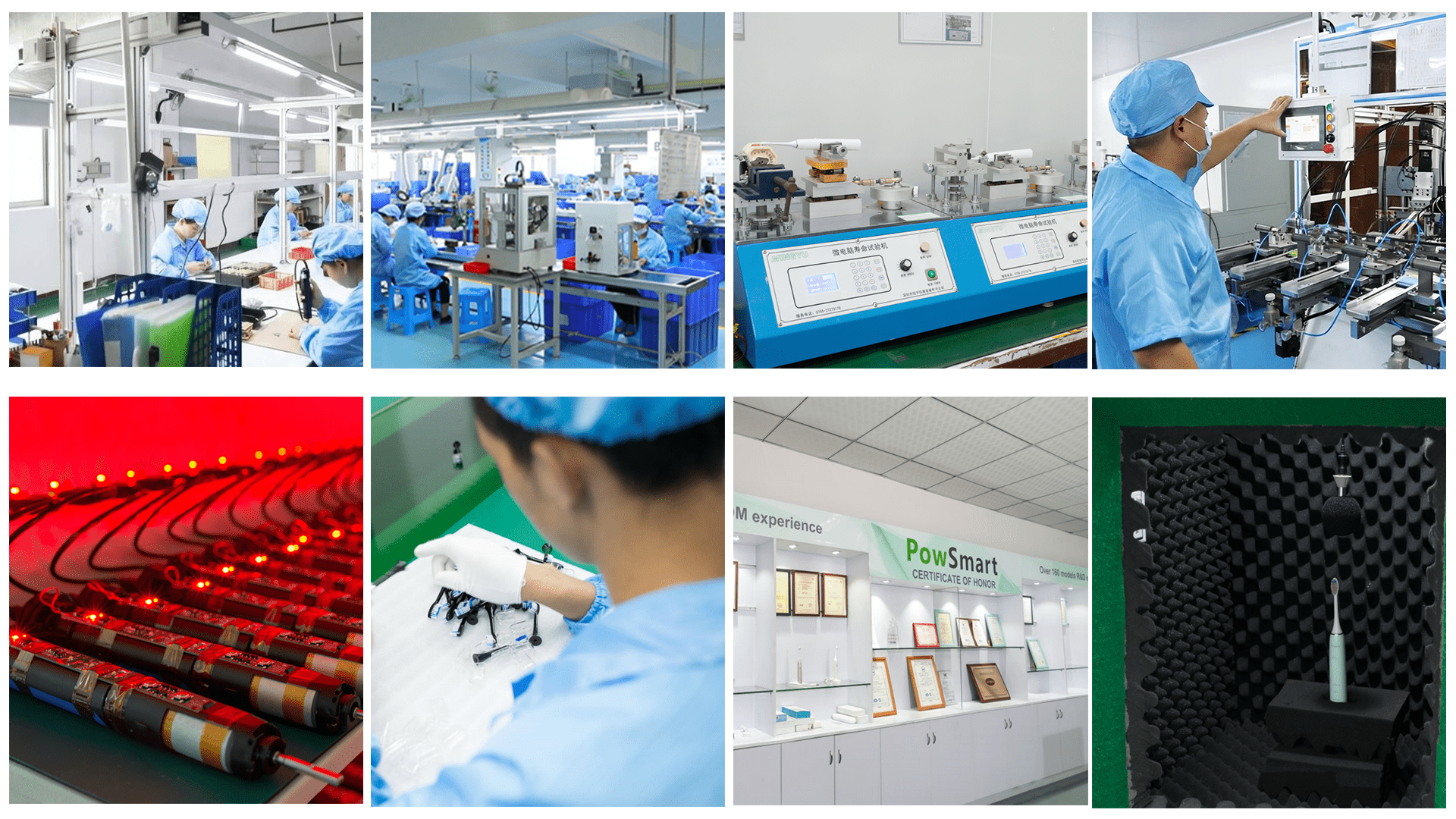

Electric Toothbrush Production Factory for OEM Manufacturing

The Ultimate Checklist for Evaluating an Oral Care Product Manufacturer

How to claim a Boston student discount on Boston clinic recommended brushes

.jpg)

Electric Toothbrush Manufacturing Company for OEM & ODM Projects