The quality of electric toothbrush bristles plays a crucial role in ensuring an optimal brushing experience. The Electric toothbrush bristle Implantation process has evolved to provide enhanced durability, comfort, and efficiency. However, choosing the right bristles requires an understanding of various factors, including material composition, manufacturing techniques, and implantation methods. In this article, we will explore how to select the most suitable bristles for electric toothbrushes, comparing different transplantation processes and analyzing bristle materials. https://www.powsmart.com/

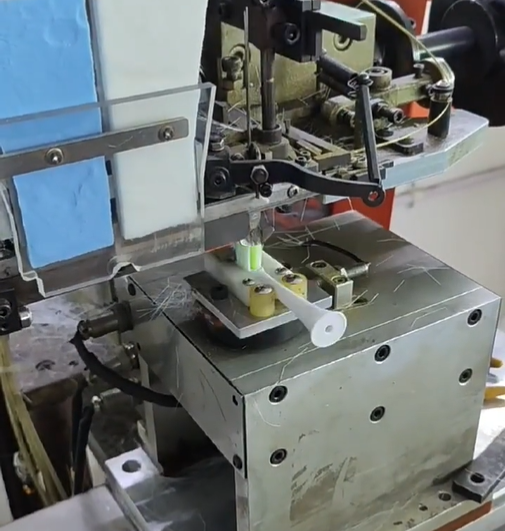

The Electric toothbrush bristle Implantation process involves embedding bristles into the toothbrush head using specialized technology. This process impacts bristle retention, durability, and overall user experience. The most common methods include:

Staple-type implantation: Traditional and widely used, this method involves embedding bristles into a brush head with the help of metal staples.

Hot-melt implantation: A more advanced technique that melts bristle bases into the toothbrush head, eliminating the need for metal staples and ensuring a softer feel.

Ultrasonic welding: This method uses ultrasonic waves to fix the bristles securely, offering superior strength and longevity.

Each technique affects the firmness and lifespan of the bristles, making it essential to choose the right transplantation method based on the target audience and usage scenarios.

Electric toothbrush bristle selection is crucial to delivering an effective and comfortable brushing experience. Consider the following factors:

Softness and Hardness: Soft bristles are ideal for sensitive gums, while harder bristles provide deeper cleaning for users with strong enamel.

Tapered vs. Flat-tip Bristles: Tapered bristles penetrate deep between teeth for better plaque removal, whereas flat-tip bristles focus on surface cleaning.

Bristle Density: Higher density bristles enhance the cleaning effect but may require a more robust implantation process.

FDA & ISO Certifications: Compliance with safety and hygiene standards ensures reliability and consumer trust.

Choosing the right bristle material is essential for both performance and safety. Below is a Bristle material analysis covering the most commonly used types:

Nylon (Nylon 610, Nylon 612, PBT): Durable, flexible, and widely used in electric toothbrushes.

Silicone Bristles: Soft and gentle, ideal for users with sensitive gums.

Charcoal-infused Bristles: Known for antibacterial properties and enhanced plaque absorption.

Bio-based Bristles: Eco-friendly alternatives that appeal to environmentally conscious consumers.

Each material has its advantages and trade-offs, influencing how well the bristles perform in different brushing scenarios.

When evaluating the Bristle transplantation process comparison, it’s essential to consider key performance factors:

| Transplantation Method | Durability | Comfort | Manufacturing Cost |

| Staple-type | High | Moderate | Low |

| Hot-melt | Medium | High | Medium |

| Ultrasonic welding | High | High | High |

The right method depends on the desired balance between production efficiency, cost, and user comfort.

High-quality bristle implantation techniques enhance brushing effectiveness, reduce gum irritation, and extend the toothbrush’s lifespan. Manufacturers must carefully select their implantation process and bristle materials to align with consumer preferences and industry trends.

Selecting the right bristles and implantation technology is critical for ensuring a high-quality electric toothbrush. By understanding the Electric toothbrush bristle Implantation process, conducting thorough Electric toothbrush bristle selection, and comparing different Bristle transplantation process comparison methods, manufacturers can create superior products. Additionally, detailed Bristle material analysis helps in choosing the most suitable materials for durability, comfort, and safety. Investing in the right technology and materials will ultimately lead to better performance, higher customer satisfaction, and long-term brand success. Powsmart offers OEM/ODM, wholesale, distribution, one-stop private label service for customer from all over the world.https://www.powsmart.com/contact-us/

The Power of Teeth Whitener & Toothbrush Bundles

Electric Toothbrush Certificate

Application and Effectiveness of Electric Toothbrush in Oral Care

College Student-Friendly Electric Toothbrush Features – Budget OEM Designs

Is a Smart Timer Whitening Kit the Ultimate Upgrade for At-home Whitening Kit Effectiveness?

.jpg)

Pregnancy Contraindications & Noise Level Concerns: Safe?

Can I Use an Electric Toothbrush in the Shower?

.jpg)

Why Do Design Flaws Cause Gum Injury in Water Flossers?

.jpg)

Electric Toothbrush Waterproof IPX7 for OEM & ODM Manufacturing

.jpg)

How Do Dock Failure and Battery Swelling Threaten Safety?

Why Is a Dental Recommended Brush with BPA-Free Brush Heads Safer?

.jpg)

Florida Periodontal Gum Care Electric Toothbrush Manufacturers: A Guide for Brand Owners

What Functions Are the Most Concerned by Electric Toothbrush Users?

.jpg)

Brush Head Blockage Causing Motor Stalling?

.jpg)

Electric Toothbrush with Extra Battery Life for RV Travelers

Technological Breakthrough in Solving Water Flosser Leakage Problem: How to Achieve Complete Leakage Prevention?