In the rapidly evolving oral care market, manufacturers are constantly seeking ways to differentiate their products. One key area of innovation lies in self-developed motor technology, particularly in electric toothbrushes. By designing and producing their own magnetic suspension sonic motors, manufacturers can achieve superior performance, reliability, and cost efficiency—giving them a significant advantage in the B2B marketplace.

A self-developed motor allows manufacturers to fine-tune the high-intensity vibration frequency to optimize cleaning efficiency. Unlike generic motors, custom-engineered solutions can deliver precise oscillations that effectively clean oral food residues and plaque, even in hard-to-reach areas. This level of performance ensures end-users receive a superior brushing experience, fostering brand loyalty.

Noise levels can make or break a consumer’s perception of an electric toothbrush. With an in-house magnetic suspension sonic motor, manufacturers can minimize mechanical friction, resulting in low noise operation. This refinement enhances user comfort, making the product more appealing in both home and travel settings.

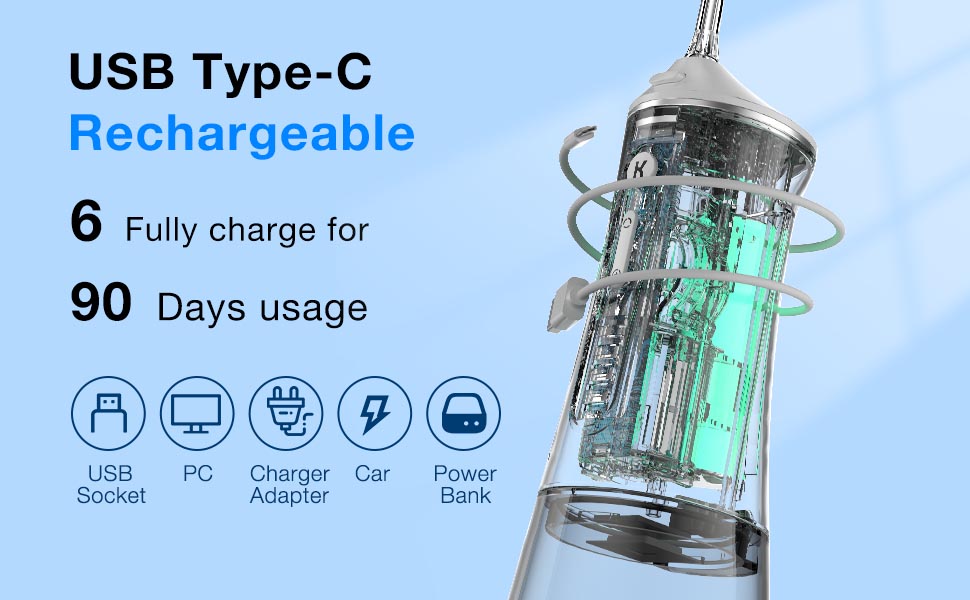

Battery life is a critical factor in consumer satisfaction. A self-developed motor can be optimized for energy efficiency, ensuring long-lasting power without compromising performance. This reduces the frequency of recharging and extends the product’s lifespan, reducing returns and increasing customer trust.

Relying on third-party motor suppliers can lead to higher costs and supply chain vulnerabilities. By developing proprietary motor technology, manufacturers gain greater control over production costs and lead times. This independence allows for scalable manufacturing and faster adaptation to market demands.

With countless electric toothbrush brands competing for attention, a self-developed motor serves as a unique selling proposition. Highlighting features like high-intensity vibration frequency, low noise, and long-lasting power in marketing materials can position a manufacturer as an innovator rather than a follower.

Owning motor technology means manufacturers can continuously upgrade and adapt their designs. Whether improving magnetic suspension sonic motor efficiency or integrating smart sensors, in-house development ensures agility in responding to industry trends and consumer demands.

For B2B manufacturers, self-developed motor technology is more than just an engineering feat—it’s a competitive necessity. By delivering high-intensity vibration frequency, low noise, and long-lasting power, brands can ensure their electric toothbrushes effectively clean oral food residues while standing out in a saturated market. https://www.powsmart.com/

.jpg)

Eco-Friendly Electric Toothbrush Manufacturer | Sustainable Oral Care

How Does a Plume Evacuation System Improve Safety in Photo-accelerated Oxidation Whitening Devices?

.jpg)

7 At-Home Dental Care Products Your Kids Will Love

.jpg)

Graduation Gift Sonic Toothbrush Houston

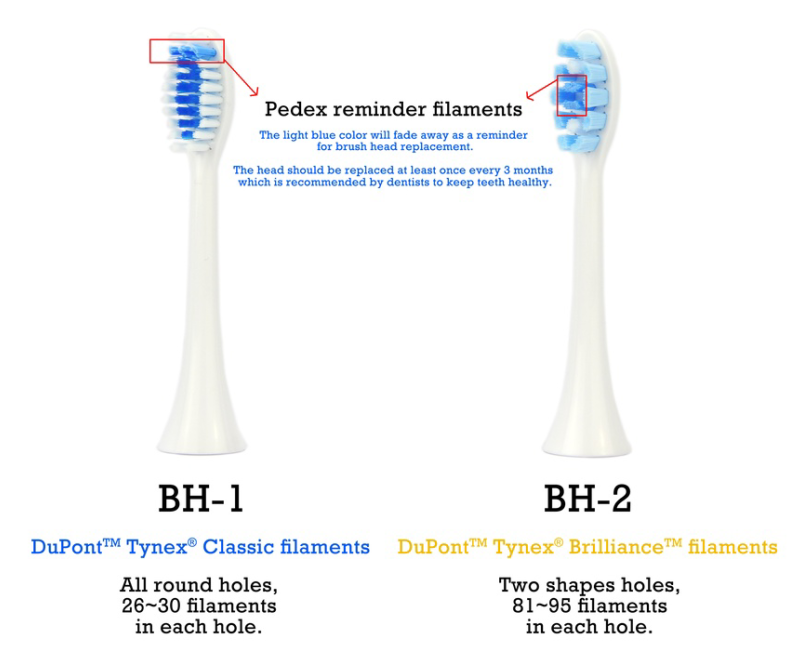

The Advantages of the Brush Head Subscription Service for Oral Care Brand Growth

.jpg)

Waterproof Sonic Toothbrush Exporter for Global B2B Distribution

Application of Water Transfer Printing and Thermal Transfer Printing on Electric Toothbrush Shell: 3D Texture and Wear Resistance Test

How Can a Sonic Toothbrush Manufacturer Collaborate on Portable Water Flosser Designs for Travel-Friendly Oral Care?

.jpg)

Can Electric Toothbrush Private Label Models Leverage Electric Toothbrush Bulk Pricing?

.jpg)

Planning Bulk Orders for a Smart Toothbrush OEM Product?

Waterproof & Fast Charging? Inside High-End electric Toothbrush Charging Stations

.jpg)

Senior-Friendly Oral Care: Design & Sourcing Considerations for Aging Adults

Oral Care Brand Style Trends 2026 – Connecting Aesthetics with OEM Strategy

Concerned About High Toothbrush Minimum Order Quantity?

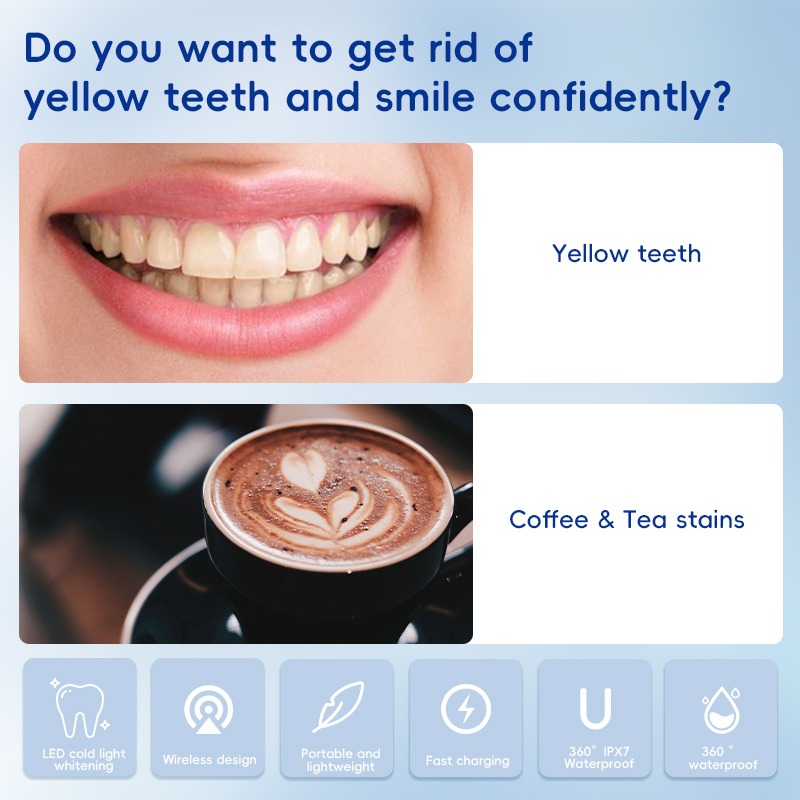

Popular At-Home Teeth Whitening Solutions

Water Flosser vs. Traditional Dental Floss: A Manufacturing Perspective