In today’s competitive oral care market, cleaning performance is a key differentiator for any electric toothbrush brand. Whether you’re launching a new line or improving your current offering, choosing the right electric toothbrush factory can make or break product performance. Key factors such as sonic technology, brush head design, and quality OEM manufacturing standards all influence the outcome. This blog explores how different factories vary and what to consider when selecting the right partner.

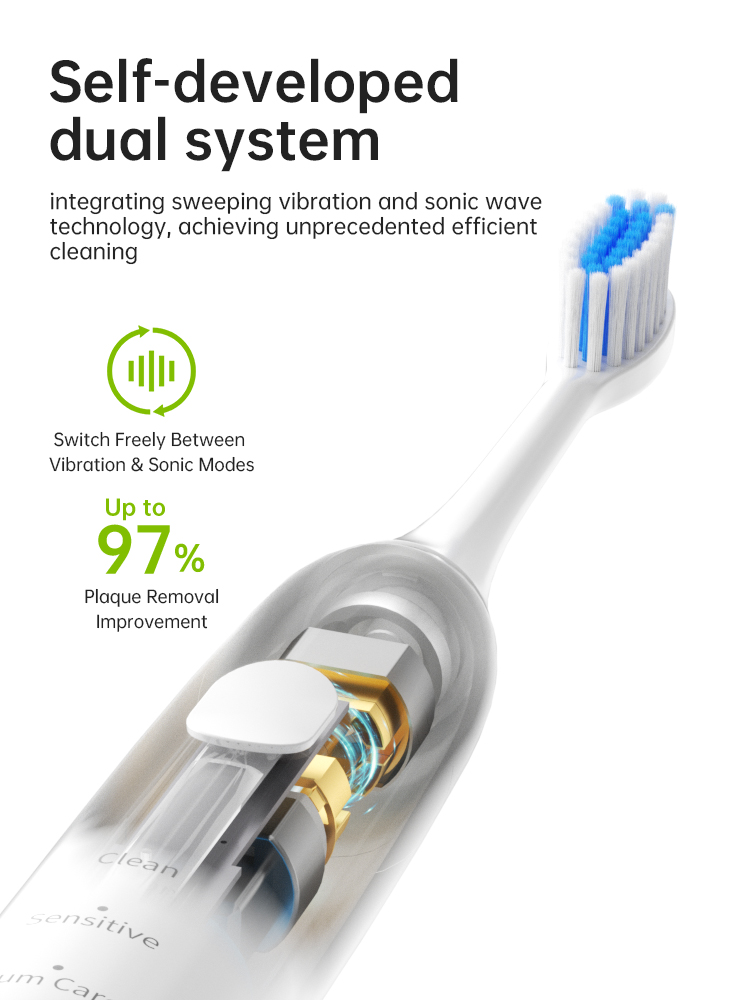

One of the primary factors impacting cleaning efficiency is the type of motor technology used. Advanced sonic technology enables toothbrushes to deliver up to 40,000 strokes per minute, creating microbubbles that reach deep between teeth and along the gum line. However, not all electric toothbrush factories implement this technology equally.

Top-tier factories invest in high-frequency, stable sonic motors.

Lower-end suppliers may compromise on vibration strength and consistency.

When selecting a supplier, always evaluate their motor sourcing and engineering capabilities to ensure your brand offers a true deep cleaning toothbrush experience.

Another critical but often overlooked component is the brush head design. Factors such as bristle material, tufting density, and head shape directly impact how effectively a toothbrush cleans.

High-quality manufacturers offer custom head molds with ergonomic angles and DuPont bristles.

Others rely on generic designs that may not deliver optimal coverage or comfort.

When comparing electric toothbrush factories, ask for prototype comparisons and test reports related to brush head design performance. Better design = better user satisfaction.

For oral care brands, OEM manufacturing is about more than just putting a logo on a product. The best factories provide full-stack support, including:

PCB & motor integration

Mold customization

Private labeling

Regulatory documentation (FDA, CE, RoHS)

The level of support and flexibility offered by a factory will impact your speed to market, product uniqueness, and compliance. Not all factories are equally equipped—some only provide white-label options with minimal adjustments.

Cleaning performance must be consistent across batches. Reliable electric toothbrush factories implement strict quality control processes, including:

Motor vibration testing

Bristle strength/durability tests

Waterproof sealing checks (IPX7 rating)

Battery and charging system validations

Ask potential partners about their QC systems, certifications, and whether they conduct real-use testing simulating consumer behavior. Without robust QC, even the best product design may result in poor market feedback.

.jpg)

To ensure your brand delivers a truly effective cleaning performance Electric toothbrush, the choice of manufacturing partner is critical. From sonic technology to brush head design and overall OEM manufacturing capabilities, there are significant differences among electric toothbrush factories.

By conducting a thorough product performance audit and assessing customization, QC, and innovation levels, you can find a partner that aligns with your product vision and business goals. Don’t settle—partner with a factory that powers your brand’s success.

Interested in sourcing high cleaning performance electric toothbrushes with proven results?

Contact us today for factory tours, prototype samples, and performance demos tailored to your brand.https://www.powsmart.com/about-powsmart/

.jpg)

Corporate Gift Supplier Alabama Dental | Custom Oral Care

Building a Zero-Waste Oral Care Line: Sourcing Eco-Conscious OEM Products

How to Choose the Right Electric Toothbrush: A Comprehensive Guide

Highly Effective Electric Toothbrush Changes Your Oral Care Habits

Forecast of the Teeth Whitening Device Industry in the Next 5 Years: Changes in Technology, Policies, and Consumption Scenarios

Retiree Toothbrush Florida vs. Florida Whitening Brush — Which One Should You Make?

.jpg)

Battery Overheating Inducing Ear Discomfort – Dangerous?

.jpg)

Electric toothbrush factory revealed: the key to efficient production and quality control

.jpg)

Ayurvedic neem toothbrush as an Indian household toothbrush

Horizontal vs Vertical Brushing: How Smart Toothbrush Design Guides Proper Technique

.jpg)

Toothbrush Product Lifecycle Management for Global OEM Buyers

Cutting-edge tech makes us apart from other electric toothbrush manufacturers

.jpg)

Chicago Black Friday: Best Electric Toothbrush Deals

Customized Packaging for Electric Toothbrushes: A Necessary Investment for Brands?

How to Care for Your Teeth While Traveling? Essential Oral Hygiene Tips for Travelers

Can a Hawaii saltwater toothbrush really outperform a standard Hawaii waterproof toothbrush?