In advanced whitening systems, Micro Bubble Technology and Colorimeter Calibration work together to deliver more precise, consistent, and measurable whitening outcomes. As manufacturers increasingly focus on quantifiable results and reliability, combining high-efficiency stain removal with accurate color evaluation has become essential. This blog explores how these two technologies enhance each other and why they are critical for next-generation whitening devices.

Micro Bubble Technology generates ultra-fine bubbles that penetrate microscopic crevices on the tooth surface. Their implosive cleaning action dislodges stains more effectively than traditional mechanical or chemical cleaning. This higher cleaning resolution creates a more uniform starting point for measuring changes in tooth color.

Accurate whitening evaluation requires precisely calibrated instruments. Colorimeter Calibration ensures that each device measures color values consistently across multiple sessions, batches, and user groups. For manufacturers, this helps verify product performance and maintain quality assurance standards.

When Micro Bubble Technology removes stains more thoroughly, the results can be more precisely captured by a calibrated colorimeter. Clean, debris-free enamel reduces measurement noise and enables more stable readings in Lab* or HSL color models, improving both clinical and consumer evaluation.

Whitening systems often suffer from variability due to surface contamination, lighting conditions, or device drift. By combining powerful micro-bubble cleaning with routine Colorimeter Calibration, manufacturers can significantly reduce variability and produce whitening results that are more predictable and repeatable across different users.

Reliable color data obtained through calibrated instruments helps R&D teams analyze whitening progression with greater accuracy. This supports formula optimization, LED wavelength adjustments, and timing improvements—ultimately enabling better integration of Micro Bubble Technology into future whitening systems.

For B2B buyers—such as dental brands, OEM partners, and distributors—demonstrable whitening accuracy is a key selling point. The dual use of Micro Bubble Technology for enhanced cleaning and Colorimeter Calibration for objective verification increases brand trust, device credibility, and long-term customer satisfaction. Contact us

.jpg)

.jpg)

Does the 40000 Strokes/Min Sonic Brush Trigger Gum Recession?

.jpg)

low noise sonic toothbrush supplier | Quiet Sonic Toothbrush OEM Manufacturer

How to Start a Private Label Teeth Whitening Brand?

.jpg)

OEM Electric Toothbrush Kirkland | Custom Dental Solutions

Can Custom Tray Design services coexist with Whitening Pen OEM production in a portfolio?

.jpg)

Charcoal-Infused Bristle Electric Toothbrush Wholesale – Premium Oral-Care Solutions

Why Should You Cover Your Toothbrush in the Bathroom? Hygiene Insights from Manufacturers

.jpg)

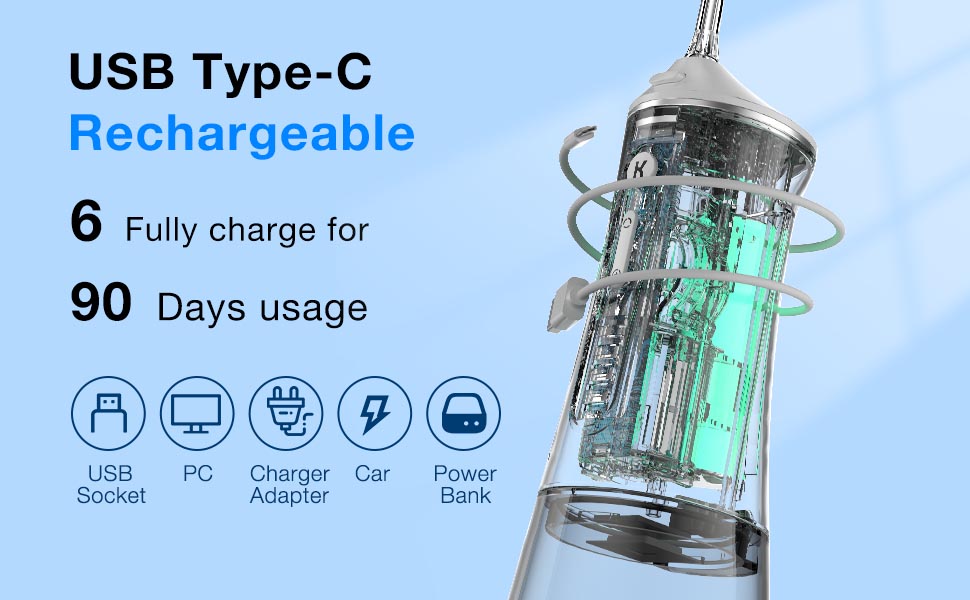

Whitening Mode USB-C Toothbrush OEM | Rechargeable Sonic Solutions

How to Fix Vibrating Toothbrush Issues via DIY Motor Troubleshooting?

Sonic Toothbrush and Internationally Certified

How to Judge Whether a factory’s R&D capabilities Is Strong?

.jpg)

What Is the Safest Teeth Whitening Method?

Are IPX7 Kids Brushes Truly Waterproof?

.jpg)

How does the UV sterilization function provide you with a sterile and clean brush head every time you brush?

Comparing Motor Types in Electric Toothbrushes: Sonic vs. Rotary for OEM Designs

Cost Control and Quality Assurance Strategy of Electric Toothbrush OEM Production