In Chicago, an electric toothbrush subscription service can convert trial into recurring sales. The city offers dense demand, fast delivery options, and rich dental channels. Therefore, brands can build steady cash flow if unit economics and supply chains align.

First, define the audience. Urban professionals want convenience. Families want bundle value. Clinics want credible products and simple billing.

Channels: neighborhood pharmacies, dental clinics, D2C, marketplaces.

Moments: back-to-school, Black Friday, insurance renewal periods.

Next, build a simple model. Keep it visible to your team.

CAC: ad cost + samples + promos.

Gross margin per kit: (AOV − COGS − pick/pack − shipping).

Refill cadence: 3 months is standard; test 2 or 4 months.

LTV: starter margin + Σ(refill margin × cycles) − churn costs.

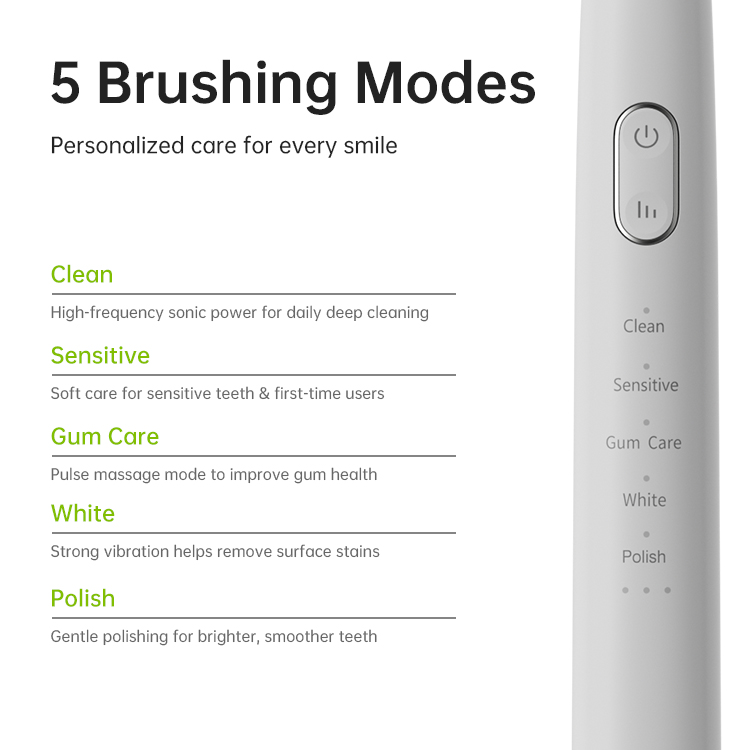

Then, design what customers actually use.

Bundles: handle + 3 heads + USB-C cable + travel cap.

Tracks: Kids, Sensitive, Ortho, Whitening.

Controls: skip, pause, swap head types anytime.

In-box aids: QR quick-start, brush charts, refill calendar stickers.

Moreover, align with a modular OEM platform.

Reuse motors, PCBs, and batteries across SKUs.

Standardize head hubs and color rings for family sorting.

Co-develop gentle and ortho heads under one tool set.

Pre-kit subscription cartons at the factory to cut 3PL time.

However, profit dies without tight ops.

3PL: place inventory in a Midwest node for 1–2-day ground.

SLA: same-day pick/pack before 2 p.m.; weekend surge plan.

RMA: drop-and-go returns with instant credit.

Repair/replace: fast-swap handles; recycle or refurbish returned units.

Finally, scale with partners.

Dental clinics: co-label starter kits; staff sampling; chair-side QR signups.

Employers and schools: benefits add-on; payroll or PTA bundles.

Local media: CTA ads, neighborhood newsletters, transit-station demos.

In short, Chicago supports a profitable electric toothbrush subscription service when math, design, and logistics align. Price for value, not just discount. Use OEM modularity to cut cost and delays. Then, anchor recurring sales with clinic partnerships and fast local fulfillment. Do this, and one starter kit becomes a reliable cash engine for your brand.

How Does a Hydro-mechanical Seal Ensure Consistent Spectral Output Optimization in LED Kits?

.jpg)

Rechargeable Oral Care Kit Supplier | Complete OEM/ODM Solutions

Why Is Universal Brush Head Compatibility a Challenge for Certification Compliance?

.jpg)

sonic electric toothbrush Chicago

How Does Osmotic Pressure Regulation Fare in Accelerated Aging Tests for Product Longevity?

.jpg)

Premium electric toothbrush OEM China

.jpg)

Electric Toothbrush with UV Cleaning Base | Advanced Oral Hygiene Solutions

How Does Integrated UV Sanitization Affect the Cartridge Replacement Cycle for Flossers?

How Does Including a Wireless Charging Module Influence Kit Packaging Design?

How Can Intuitive Touch Interface Design Incorporate a Reliable Child Lock Function?

.jpg)

Electric Toothbrush Packaging Compliance for Global Markets

Does an FDA Approved Device Inherently Guarantee Sensitivity Reduction?

.jpg)

Toothbrush Private Mold Development for OEM & ODM Brands

.jpg)

Chicago holiday deals on a Chicago subscription toothbrush — worth it?

.jpg)

Downtown Chicago Electric Toothbrush Repair Services

.jpg)

Toothbrush Export Documentation for Global OEM Shipments