With the increasing popularity of electric toothbrushes, ensuring their durability and longevity has become a key concern for both manufacturers and consumers. One of the most common issues affecting product performance is the water ingress problem in electric toothbrush charging ports. When water seeps into the charging port, it can cause short circuits, corrosion, and device failure.

From a manufacturing perspective, preventing water damage requires careful engineering, material selection, and production techniques. In this article, we will analyze the causes of water ingress, explore effective prevention tips for water ingress problems, and discuss advanced solutions to enhance the reliability of charging ports.

The charging port of an electric toothbrush is exposed to a high-moisture environment due to regular use in bathrooms. Water ingress can occur due to:

Condensation: Steam from hot water can accumulate inside the device.

Direct exposure: Splashes from rinsing or accidental submersion in water.

Capillary effect: Water creeping into small gaps in the charging port design.

If not addressed properly, water ingress can lead to:

Electrical failure – Short circuits and malfunctions.

Corrosion – Internal components degrade over time.

Reduced lifespan – Frequent replacements and increased warranty claims.

Manufacturers need to be aware of key weaknesses in electric toothbrush charging ports that can make them vulnerable to water ingress:

Poor Sealing Mechanism – Inadequate waterproofing around the charging port allows moisture to enter.

Inferior Materials – Non-water-resistant materials degrade quickly when exposed to humidity.

Ventilation Issues – A lack of proper ventilation can trap moisture inside the device.

By understanding these weaknesses, manufacturers can develop more effective prevention tips for water ingress problems.

To enhance the durability of electric toothbrush charging ports, manufacturers should consider the following strategies:

✅ IP Rating Enhancement

Utilize IPX7 or higher waterproof ratings to ensure protection against water immersion.

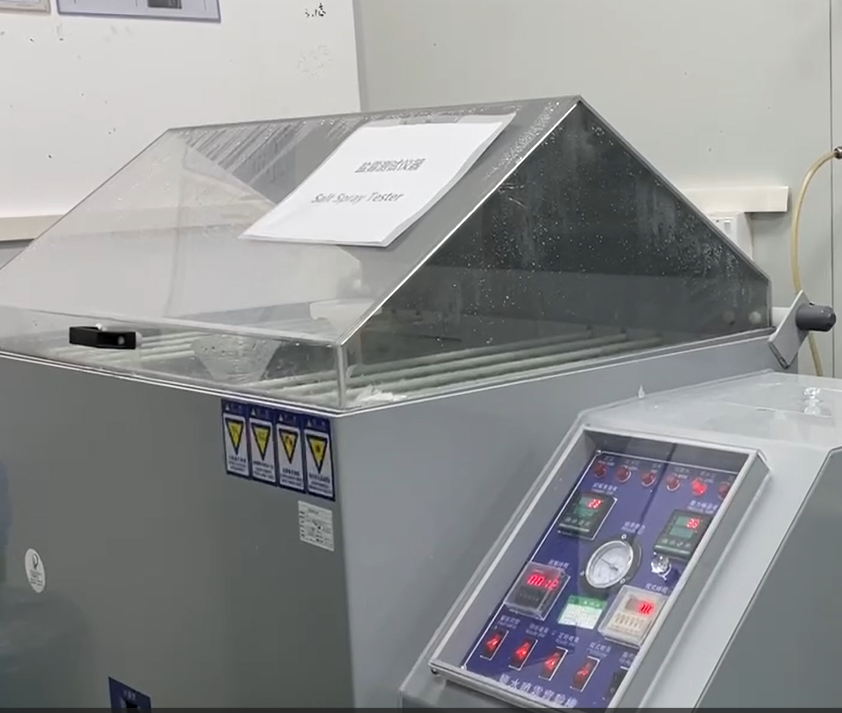

Implement rigorous testing to verify compliance with waterproof standards.

✅ Improved Sealing Technologies

Apply silicone gaskets or rubber seals around the charging port.

Use ultrasonic welding to eliminate small gaps where water could enter.

✅ Hydrophobic Coating Application

Coat the charging port and internal components with water-repellent nanocoatings to reduce moisture absorption.

✅ Wireless Inductive Charging

Consider eliminating exposed metal connectors by adopting inductive charging technology.

Wireless charging removes direct contact points, significantly reducing the risk of water ingress.

✅ Drainage and Ventilation Design

Incorporate small drainage channels to direct water away from the charging port.

Use breathable membranes to prevent moisture buildup inside the device.

By integrating these prevention tips for water ingress problems into the design process, manufacturers can produce more reliable and long-lasting electric toothbrush charging ports.

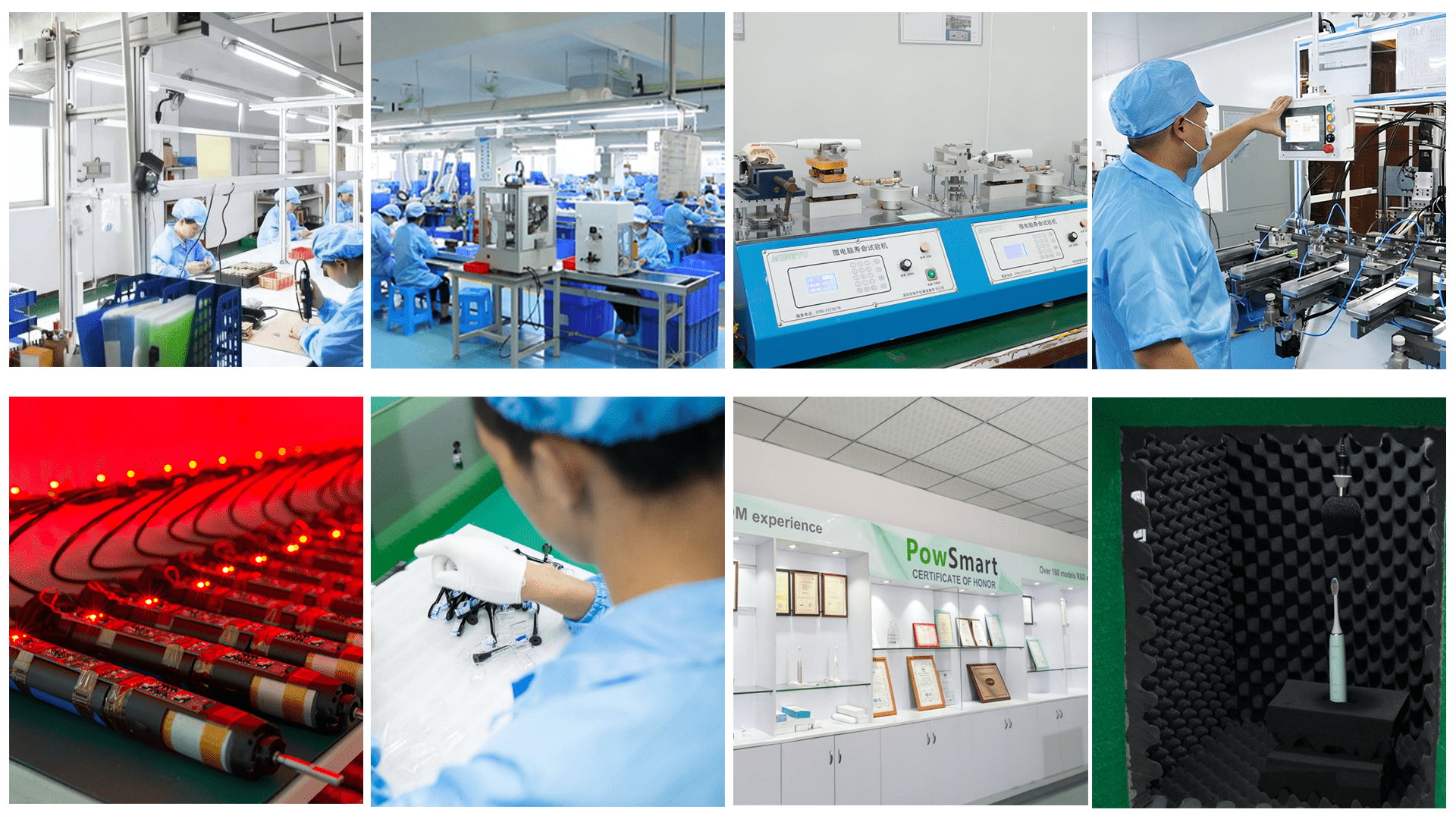

To achieve superior water resistance, manufacturers are adopting cutting-edge production techniques, including:

Injection Molding with Waterproof Materials – High-precision injection molding ensures a tight seal around the charging port.

Laser Welding for Seamless Joints – Eliminates gaps and enhances durability.

Automated Quality Control Inspections – Using AI-powered cameras to detect micro-leaks in waterproof enclosures.

By leveraging these innovations, manufacturers can enhance the reliability of electric toothbrush charging ports and extend product lifespan.

As the industry evolves, future electric toothbrushes will feature:

Completely Sealed Designs – No exposed charging ports, fully relying on wireless charging.

Smart Moisture Sensors – AI-driven sensors that detect and prevent water damage in real time.

Eco-Friendly Waterproof Materials – Sustainable, biodegradable coatings that provide long-term protection.

By staying ahead of these trends, manufacturers can continue to improve product durability and customer satisfaction.

Preventing the water ingress problem in electric toothbrush charging ports is a crucial aspect of product design and manufacturing. By implementing advanced waterproofing strategies, using high-quality materials, and adopting innovative sealing techniques, manufacturers can significantly improve product reliability.

For brands looking to enhance their charging port technology, investing in waterproofing advancements will not only increase consumer trust but also reduce long-term maintenance costs. By focusing on these prevention tips for water ingress problems, the industry can continue to deliver high-performance, durable electric toothbrushes.

.jpg)

Texas Electric Toothbrush – Powsmart PTR-C8 Long Battery

Waterproof Electric Toothbrush OEM Solutions for Healthcare Workers in Texas

Tooth Flosser Market Demand Forecast and Capacity Planning

Battery Drain and Compatibility Issues Triggering Claims?

Deep Clean Interdental Electric Toothbrush Manufacturing Solutions

How to Find an Electric Toothbrush Factory with Strong Comprehensive Capabilities

Biofilm Regrowth Inducing pH Imbalance – Vicious Cycle?

How Do Water Flosser Connector Parts Enable Versatile Multi-mode Water Flosser Functionality?

Is Your Water Flosser Leakage Due to Poor ESD Packaging?

Does Your Brush Fight Plaque Smartly?

The Role of Blue and Red Light in Teeth Whitening Devices You Should Know

How does a sonic toothbrush work?

Integrating App Connectivity in OEM Electric Toothbrushes: A Tech Overview

The Higher the Frequency of the Electric Toothbrush, the Better the Cleaning Ability?

Electric Toothbrush Christmas Gift Texas

Water Flosser Toothbrush Combo: 2-in-1 Oral Care Solution

electric toothbrush heads Deep Clean

Electric toothbrush heads Charcoal Infused-Diamond

electric toothbrush heads Ultra Soft

electric toothbrush heads Charcoal Infuse-Round

.jpg)

Florida Electric Toothbrush – Powsmart PTR-C8

Customization Teeth Whitening Gel

Private Label Whitening Gel

electric toothbrush heads Regular Clean

whstapp

whstapp

National Toll-Free Service Hotline

+86 755 86238638