As portability and convenience become key selling points in oral care, the Travel Electric Toothbrush is seeing a surge in demand across global B2B channels. However, with compact size and mobile usage comes a heightened reliance on waterproof integrity. A frequently overlooked but critical concern is: Can waterproof failure in a travel electric toothbrush lead to internal circuit corrosion?

The short answer is yes—and the implications for reliability, safety, and brand credibility are severe. This blog dives deep into how waterproof failure occurs, its direct link to circuit corrosion, and how manufacturers can proactively address the issue.

A Travel Electric Toothbrush typically integrates a compact high-speed motor, lithium-ion rechargeable battery, microcircuit control board, and pressure-sensitive brushing feedback—all within a slim enclosure.

Because these components are tightly packed and often exposed to water during brushing, waterproofing becomes not just a cosmetic feature, but a critical functional protection barrier. Failure in this area can compromise the entire device’s integrity.

To defend against moisture infiltration, quality toothbrush manufacturers employ:

However, cost-cutting, inconsistent production, or aging seals can compromise these protective measures, leading to waterproof failure over time.

Despite the engineering precautions, several factors contribute to waterproof failure in travel electric toothbrushes:

B2B buyers must be aware that even slight seal failure can create a pathway for moisture intrusion.

Once moisture breaches the inner housing, it may not trigger immediate device failure. Instead, it slowly degrades the circuit board via:

What starts as a waterproof failure silently evolves into performance degradation, reduced lifespan, or even hazardous malfunction during travel.

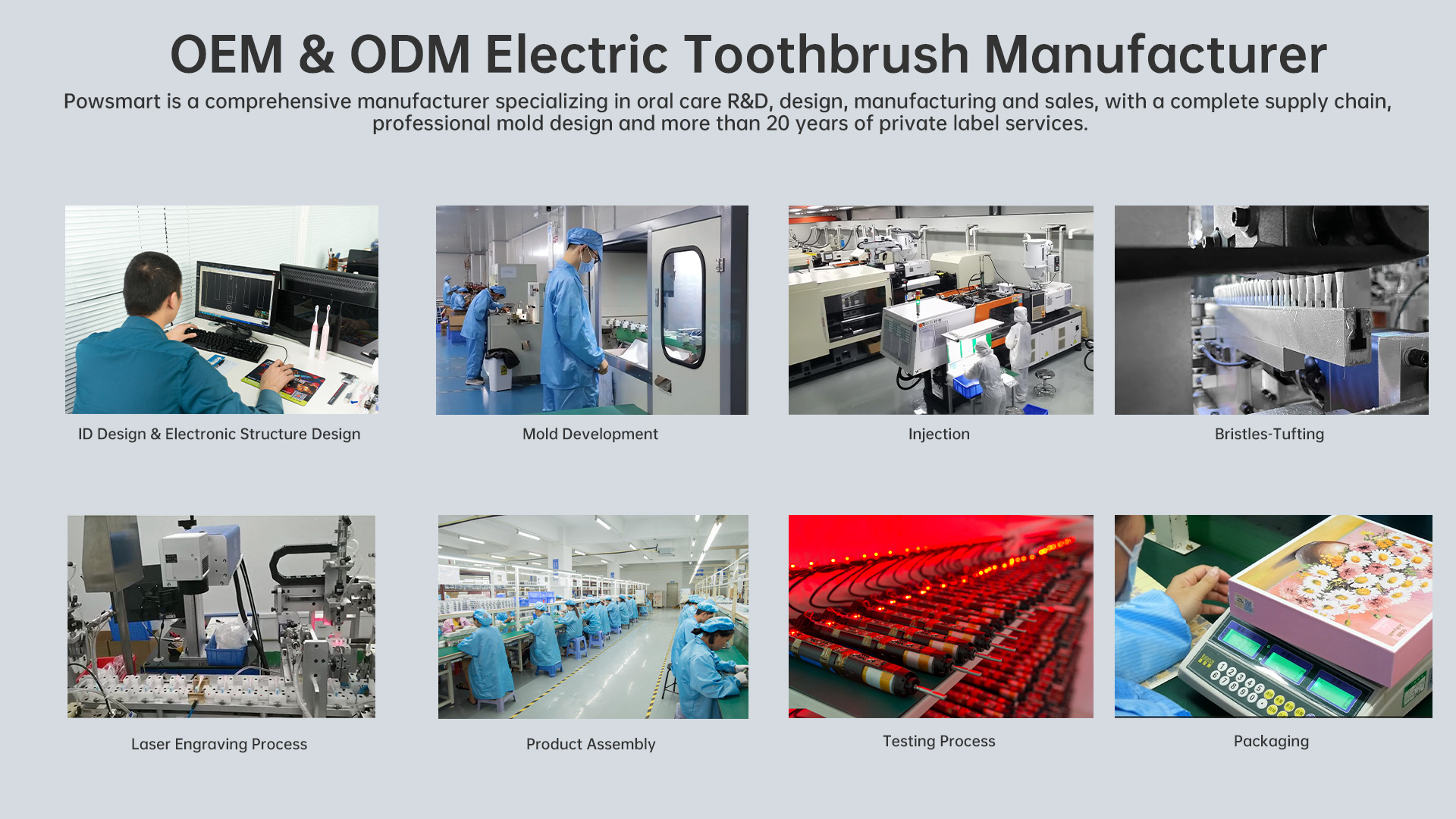

At POWSMART, we recognize these risks and integrate multiple anti-corrosion defenses into our travel toothbrush line:

These investments help our OEM/ODM partners guarantee reliability, even in challenging portable environments.

Toothbrush portability shouldn’t come at the cost of product longevity or user safety. Waterproof failure in a Travel Electric Toothbrush may seem minor at first—but left unaddressed, it can corrode internal circuits, lead to device failure, and erode user trust.

For B2B brands sourcing through OEM/ODM partnerships, verifying waterproof engineering is not just about IP ratings—it’s about understanding failure pathways and selecting suppliers who proactively mitigate them. With the right design and quality controls in place, circuit corrosion can be avoided—and long-term reliability ensured. Contact us

-300x300.jpg)

.jpg)

Why Choose a Toothbrush Sourcing Agent for Toothbrush with Pressure Sensor?

How to choose a reliable electric toothbrush factory?

.jpg)

Corporate Gift Electric Toothbrush Wholesale | Premium Business Gifts

Benefits of Electric Toothbrushes: Why Brands Should Invest in electric toothbrush Quality Manufacturing

.jpg)

electric toothbrush OEM with timer

.jpg)

How to Prevent Water Discoloration and Microbial Growth?

Efficient production line optimization and quality improvement for tooth flosser factory

.jpg)

Ayurvedic Electric Toothbrush | Natural Meets Modern

.jpg)

Water Flosser with UV Sanitizer ODM | Smart Oral Care Solutions

Are More Expensive Electric Toothbrushes Better?

Is Blue Light Under 480nm Safe for Teeth Whitening Devices?

.jpg)

Whitening Mode USB-C Toothbrush OEM | Rechargeable Sonic Solutions

.jpg)

How can a wedding guest brush be a Texas culture brush masterpiece?

.jpg)

Can a Magnetic Levitation Motor Define a Quiet Toothbrush Manufacturer?

Meeting the Demand for Advanced Oral Hygiene – Points of view from Innovative Water Flosser Supplier

water Flosser Technology Innovation Leads to New Oral Care Trends