toothbrush molding factory China sourcing is a foundational step for brands developing electric or manual toothbrush products. Injection molding quality directly affects product durability, waterproof performance, and visual consistency.

For B2B buyers, selecting the right molding partner reduces long-term production risk and cost variability.

A professional toothbrush molding factory China focuses on precision tooling and material control. Handle geometry, internal cavity accuracy, and sealing structures are all formed during the molding stage.

Moreover, high-quality molds ensure repeatability across millions of units. This consistency is essential for maintaining product specifications over extended production cycles.

Factories with in-house tooling capabilities provide faster iteration and better confidentiality protection.

Advanced molding factories support mold flow analysis, prototype validation, and durability testing. These steps help prevent defects such as warping, shrinkage, or uneven wall thickness.

In addition, material selection plays a key role. ABS, TPE, and food-grade plastics are commonly used depending on product positioning and regulatory requirements.

Powsmart works with integrated molding solutions to support electric toothbrush OEM and ODM projects. Related manufacturing services can be reviewed at:

https://www.powsmart.com/

Long-term mold performance requires routine maintenance and inspection. Professional factories track mold usage cycles and perform preventive servicing.

Furthermore, dimensional inspections ensure molded parts remain within tolerance. These practices reduce assembly issues and improve final product quality.

Manufacturing best practices for injection molding can be referenced through ISO resources:

https://www.iso.org/

Local sourcing within China allows molding factories to access mature material supply chains. This advantage helps stabilize costs and lead times for B2B buyers.

At the same time, integrated molding and assembly shorten production cycles and reduce coordination complexity.

From a business perspective, strong molding capability enables faster product updates and better cost control. Brands benefit from consistent quality and scalable output.

In conclusion, choosing a reliable toothbrush molding factory China provides the technical foundation for durable, compliant, and scalable toothbrush production.

.jpg)

Do Mode Malfunction and Pulse Instability Compromise Device Stability?

The Working Principle of Sonic Electric Toothbrushes

.jpg)

Travel Size Electric Toothbrush Wholesale

.jpg)

Smart Toothbrush Austin – High-Tech Oral Care Solutions

.jpg)

Premium electric toothbrush OEM China

.jpg)

Kids Electric Toothbrush Bulk Supplier for Schools and Clinics

Life cycle of Electric Toothbrushes! Its Components and Effects

Is a Quiet Electric Toothbrush Best for Seattle Apartments?

.jpg)

Battery Depletion with Pressure Fluctuation – Linked?

Hydrogen Peroxide vs. Carbamide Peroxide: Which Whitening Gel Formula is Right for You?

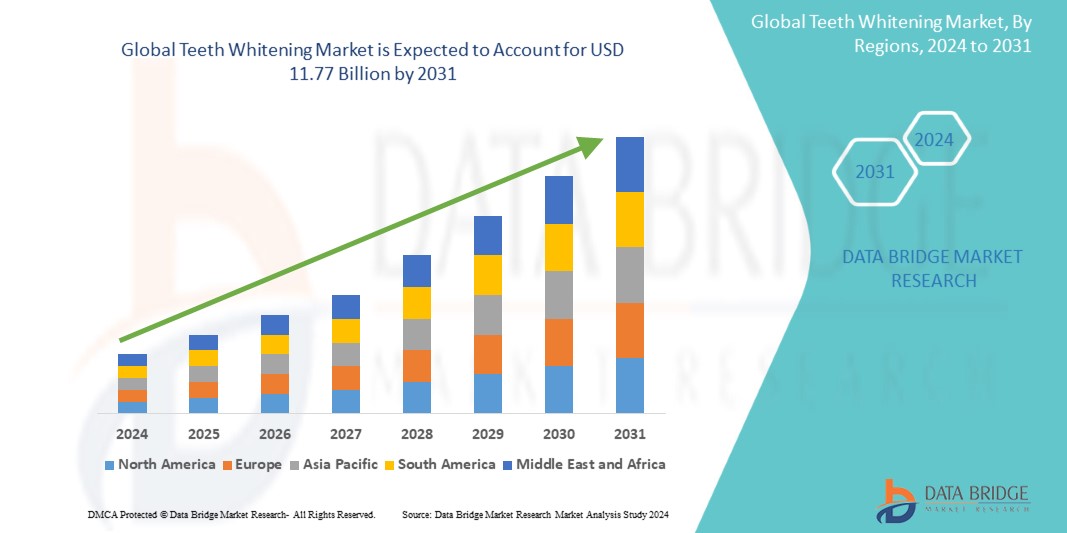

Global teeth whitening Device Market : Fastest Growing Regions and Consumer Group Portraits

.jpg)

Electric Toothbrush with App Connectivity – Smart Oral Care for B2B Markets

.jpg)

Best Toothbrush Heads Compared

How Can Smart App Connectivity Boost User Engagement Through Bluetooth App Integration?

New Year Present for Tech-Savvy Users: Premium Oral Care Products Options

.jpg)

Teeth Whitening Device OEM | Professional Smile Technology