When sourcing from overseas factories, many buyers face challenges related to Toothbrush minimum order quantity (MOQ). For small and mid-sized distributors, retailers, or brand startups, a high MOQ can create barriers to entry and strain cash flow. Understanding how to navigate MOQ requirements—and leveraging toothbrush sample requests effectively—can make your procurement process more flexible, cost-efficient, and low-risk.

In this blog, we’ll explore six practical strategies for managing MOQ expectations, optimizing supplier communication, and securing better production terms with your toothbrush manufacturing partner.

The Toothbrush minimum order quantity represents the smallest number of units a manufacturer is willing to produce in a single batch. It’s typically based on production efficiency, mold setup costs, and material purchasing requirements.

For toothbrush manufacturers, MOQ helps maintain consistent production flow and quality control. However, buyers should view MOQ not as a fixed rule but as a negotiation starting point—especially when dealing with suppliers experienced in export manufacturing.

Submitting toothbrush sample requests before confirming bulk orders serves two important functions: product verification and relationship building. Samples allow you to evaluate material quality, ergonomics, and packaging before committing to large-scale production.

Suppliers that accommodate flexible toothbrush sample requests demonstrate reliability and customer focus. This approach also opens discussions about potential MOQ adjustments if the buyer is testing new designs or entering new markets.

High toothbrush minimum order quantity requirements can lead to excess inventory and higher warehousing costs. To prevent overstocking, buyers can explore tiered order models—placing smaller initial orders with scaling potential as market demand grows.

In many cases, suppliers may offer pilot production runs or shared-mold arrangements that reduce MOQ while maintaining production quality. This flexibility is ideal for private-label toothbrush brands or market test phases.

Not all suppliers operate under rigid MOQ terms. Many modern toothbrush factories—especially those serving multiple export markets—offer adaptive solutions such as mixed-model production or partial runs.

When evaluating factories, prioritize those open to toothbrush sample requests and transparent about MOQ flexibility. A supplier with diverse production lines and in-house tooling can adjust manufacturing quantities more efficiently without compromising timelines.

Strong supplier relationships can significantly influence toothbrush minimum order quantity terms. By establishing trust through consistent communication, timely payments, and repeat orders, buyers gain leverage for negotiating smaller batches or customized runs.

Suppliers often reward long-term clients with lower MOQ thresholds, better lead times, and access to exclusive designs. Over time, this collaboration builds a more strategic sourcing model rather than transactional, short-term procurement.

To effectively negotiate MOQ terms, present data-driven forecasts and distribution plans. If you can demonstrate clear sales projections or marketing rollouts, your manufacturer may be more willing to adjust MOQ or provide extended payment terms.

Combine this with initial toothbrush sample requests and prototype evaluations to show commitment and reduce supplier risk perception. A well-documented sourcing plan reflects professionalism and increases the chances of more favorable order conditions.

Managing toothbrush minimum order quantity challenges requires strategic communication, market understanding, and supplier cooperation. By making smart use of toothbrush sample requests, developing long-term relationships, and presenting reliable demand forecasts, buyers can achieve flexible, cost-effective production outcomes.

? Looking for a manufacturer that balances MOQ flexibility with top-quality toothbrush production? Contact our team to explore customized solutions tailored to your order scale and market goals.

.jpg)

.jpg)

.jpg)

Compact Size Sonic Toothbrush Wholesale | Lightweight Travel-Friendly OEM Supply

.jpg)

OEM smart toothbrush manufacturer

.jpg)

Electric Toothbrush for Elderly Care Facilities – Gentle, Efficient, and Hygienic Oral Care for Seniors

.jpg)

How Does a Thermochromic Indicator Provide Safety With an Oral Mucosa Barrier in Whitening Gels?

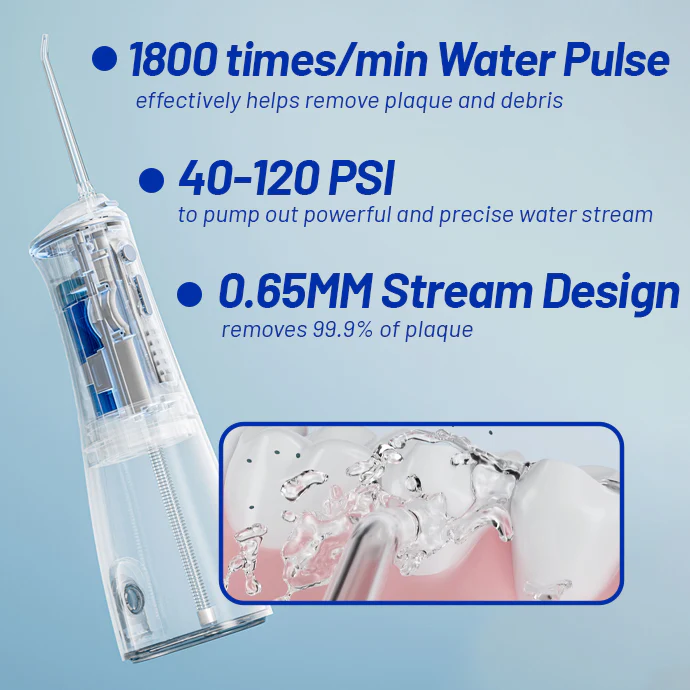

Solutions for Water Flosser Having Unstable and Intermittent Water Flow

.jpg)

How Does Battery Leakage Cause Valve Sticking?

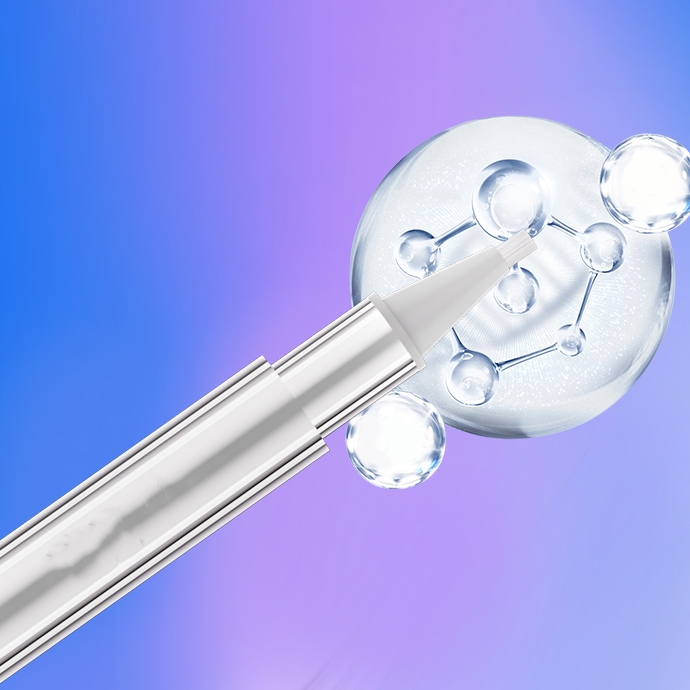

Teeth Whitening Pen OEM: On-the-Go Whitening Solutions

Want Hollywood smiles? Dental veneers via cosmetic dentistry — worth it?

.jpg)

Wholesale Waterproof Electric Toothbrush Washington Outdoor | Adventure Ready

Proper Teeth Cleaning Techniques with Electric Toothbrushes: Guide for OEM Manuals

Benefits of Travel-Sized Oral Care Products

.jpg)

How Crown Compatibility Aligns with Pressure Sensors Tech?

.jpg)

Compact Electric Toothbrush for Boston Dorms

New Trends in the Electric Toothbrush Industry: How Can Intelligent Connectivity Enable Brand Premium?

.jpg)

water flosser OEM factory

What Electric Toothbrush Do Periodontists Recommend? Insights for OEMs