Sustainability only works when engineering, retail, and reverse logistics move together. For electric-toothbrush brands and OEM/ODM partners, the Seattle recycling program is the perfect stage to prove circular design—especially when showcased at a high-visibility Seattle demo store. Below are six B2B essentials to launch, measure, and scale a credible take-back loop for brushes, heads, chargers, and batteries.

First, establish what the Seattle recycling program accepts and why it matters to your P&L.

Next, turn the Seattle demo store into a hands-on circularity hub.

Moreover, recycling performance starts at CAD, not at the bin.

Meanwhile, align incentives so customers want to return parts.

Furthermore, design a backend that’s safe, auditable, and cost-controlled.

Finally, instrument the pilot and let data drive expansion.

To make circularity real for electric toothbrushes:

Want a turnkey package (store signage, SOPs, CAD DfD checklist, QR/credit flows, and KPI dashboard) tailored to your electric toothbrush SKUs? I can deliver a production-ready draft for immediate deployment. Contact us

.jpg)

.jpg)

Is replacement head cost an important factor when choosing an electric toothbrush?

Capitalizing on the LED Oral Care Boom: Essential Market Insights for Brands

Effects of an Electric Toothbrush Combined with 3-Color Light: An OEM Analysis

.jpg)

Electric Toothbrush for Senior Living Facilities | Gentle & Easy-Care Design

.jpg)

Why Water Flosser Pressure Calibration Matters for OEM Buyers

Hydrogen Peroxide vs. Carbamide Peroxide: Which Whitening Gel Formula is Right for You?

How Does Packaging Customization Service Assist with Aesthetic Device Compliance?

No Designer? No Problem. The OEM Path to Your Successful Oral Care Brand

.jpg)

Electric Toothbrush Supplier China for OEM & Bulk Distribution

.jpg)

Electric Toothbrush Private Label Supplier | Build Your Custom Brand Line

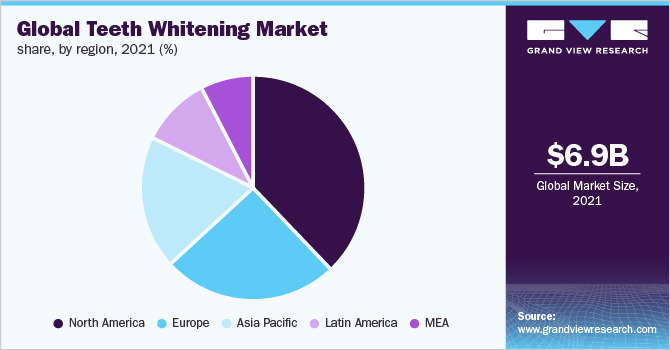

Analysis of Differences in Preferences for Teeth Whitening Devices in the European and American Markets vs. Asian Markets

.jpg)

Professional Dental Care Toothbrush Bulk | Trusted Hygiene for Clinics

How Does Bulk Toothbrush Heads Wholesale Benefit from Innovative Electric Toothbrush Mold Design?

.jpg)

Can a kids electric toothbrush make childrens dental care fun?

How Long Should I Use Blue Light on My Teeth? OEM Manufacturer’s Guide

How to Keep Teeth Clean with Braces: A Complete Care Guide