Finding a reliable quiet motor toothbrush factory has become a priority for global distributors and private-label brands seeking premium user experience and strong product differentiation. Noise levels are increasingly important in consumer purchasing decisions, especially for adult sonic toothbrushes marketed as premium or travel-friendly models. As a result, buyers now focus on sourcing manufacturers with advanced motor engineering, stable QC systems, and customizable OEM solutions.

Consumers expect electric toothbrushes to provide both strong cleaning power and quiet operation. Therefore, suppliers that specialize in low-noise motor design can offer a significant competitive advantage to oral-care brands. Meanwhile, the demand for low-decibel models continues to grow in Europe, the U.S., Japan, and the Middle East.

Professional suppliers such as:

https://powsmart.com/electric-toothbrush/

provide proprietary motor systems, stable PCBA tuning, and advanced damping structures.

Additionally, buyers can refer to the American Dental Association for brushing recommendations and product safety guidelines:

https://www.ada.org/

A qualified supplier meets global standards through consistent engineering and material selection. Moreover, noise optimization is performed through multiple elements including:

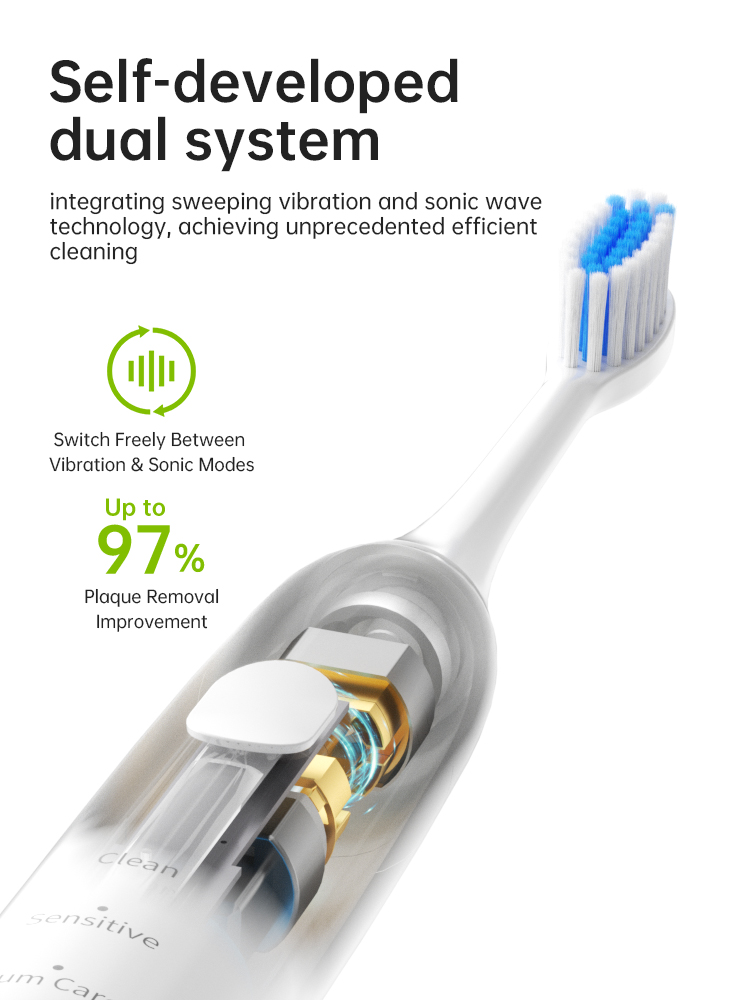

Customized high-frequency sonic motors

Balanced counterweight structures

Sound-dampening internal frames

Vibration and resonance control

Optimized gear transmission

A quiet sonic toothbrush helps brands market:

Premium user comfort

Better nighttime usability

Improved perception of product quality

Enhanced brand positioning

A strong quiet motor toothbrush factory integrates these elements into scalable production.

Distributors often require flexible customization to launch competitive product lines. Therefore, factories offer:

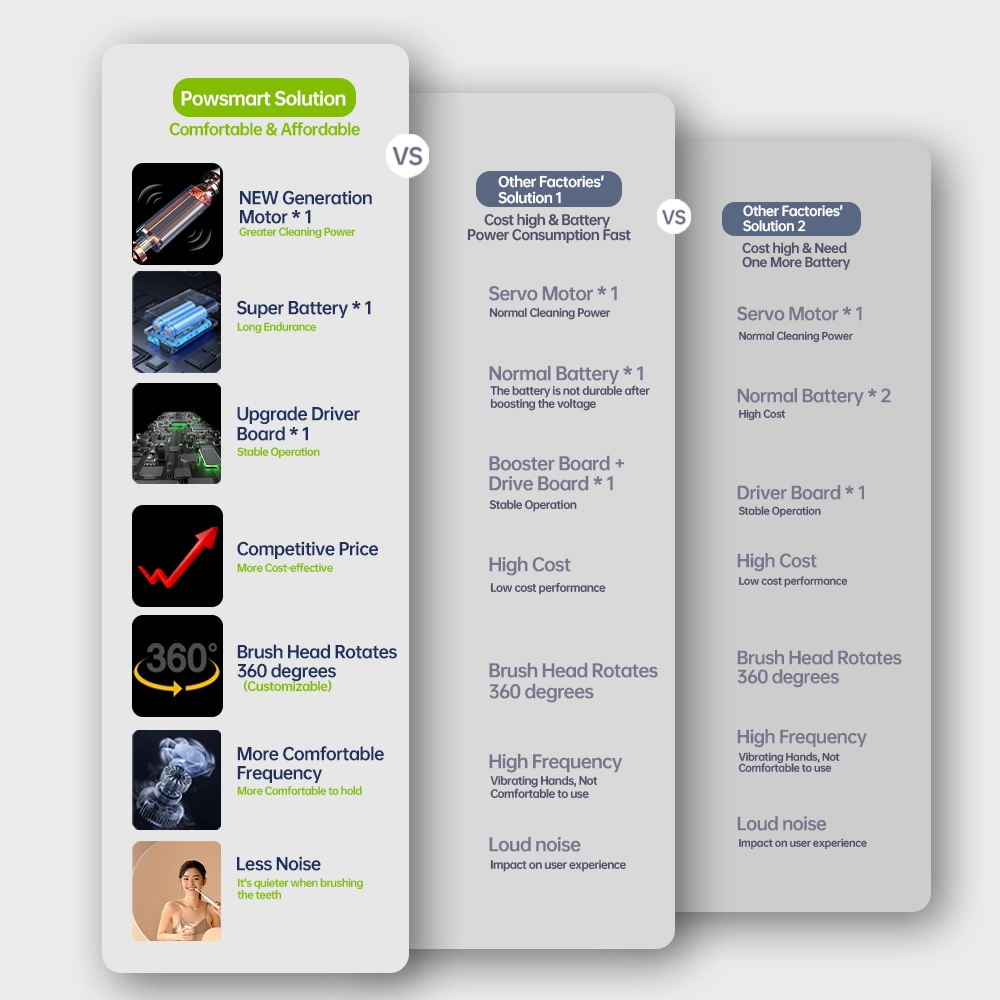

Custom motor tuning

Soft or medium bristle configurations

Mold customization

USB-C charging modules

Multiple brushing modes

Color and surface finishing

These capabilities allow buyers to build a complete product range tailored to different markets.

Low-noise performance requires strict QC. Consequently, export factories perform:

Decibel level testing

Motor vibration testing

Waterproof sealing verification

Brush-head pull testing

Drop and durability tests

This ensures product consistency across large orders.

Export-focused manufacturers offer benefits such as:

CE / RoHS / FCC documentation

Flexible MOQs

25–35 day mass-production timelines

FOB, CIF, or DDP shipping options

Stable brush-head replenishment

Partnering with an experienced quiet motor toothbrush factory enables brands to launch superior low-noise sonic toothbrushes with enhanced user experience, stable engineering, and scalable OEM options.

Is it Good for Teeth That the Power Level of a Water Flosser Is Too Strong?

Seeking a Toothbrush for Dental Clinics Produced by an ISO13485 Electric Toothbrush Factory?

.jpg)

Preparing for Toothbrush Supplier Negotiation?

.jpg)

Electric Toothbrush for Elderly Care Facilities – Gentle, Efficient, and Hygienic Oral Care for Seniors

New Year Health Goal Products Category Expansion

Analysis of the Core Components of the Electric Toothbrush: Technical Secrets from the Motor to the Brush Head

How to Store a Toothbrush? Best Practices for Hygiene and Longevity

Environmentally Friendly Manufacturing and Sustainable Development of Electric Toothbrushes

How to Maintain Good Oral Hygiene Without Irritation?

Waterproof Technology Patent in LED Teeth Whitening Devices: How to Improve Product Life?

Application of Phototherapy Technology in Teeth Whitening and Oral Care

.jpg)

When Selecting Products, How Can You Make the Pricing of Electric Toothbrushes Best Suit Your Brand Image?

.jpg)

Electric Toothbrush with Travel Case OEM

.jpg)

How Can a Travel-Friendly Water Flosser Open Up the Young Market Through Portable Size + IP Collaboration?

.jpg)

Bulk Personalized Electric Toothbrush Gifts | Corporate & Dental

What Functions Are the Most Concerned by Electric Toothbrush Users?